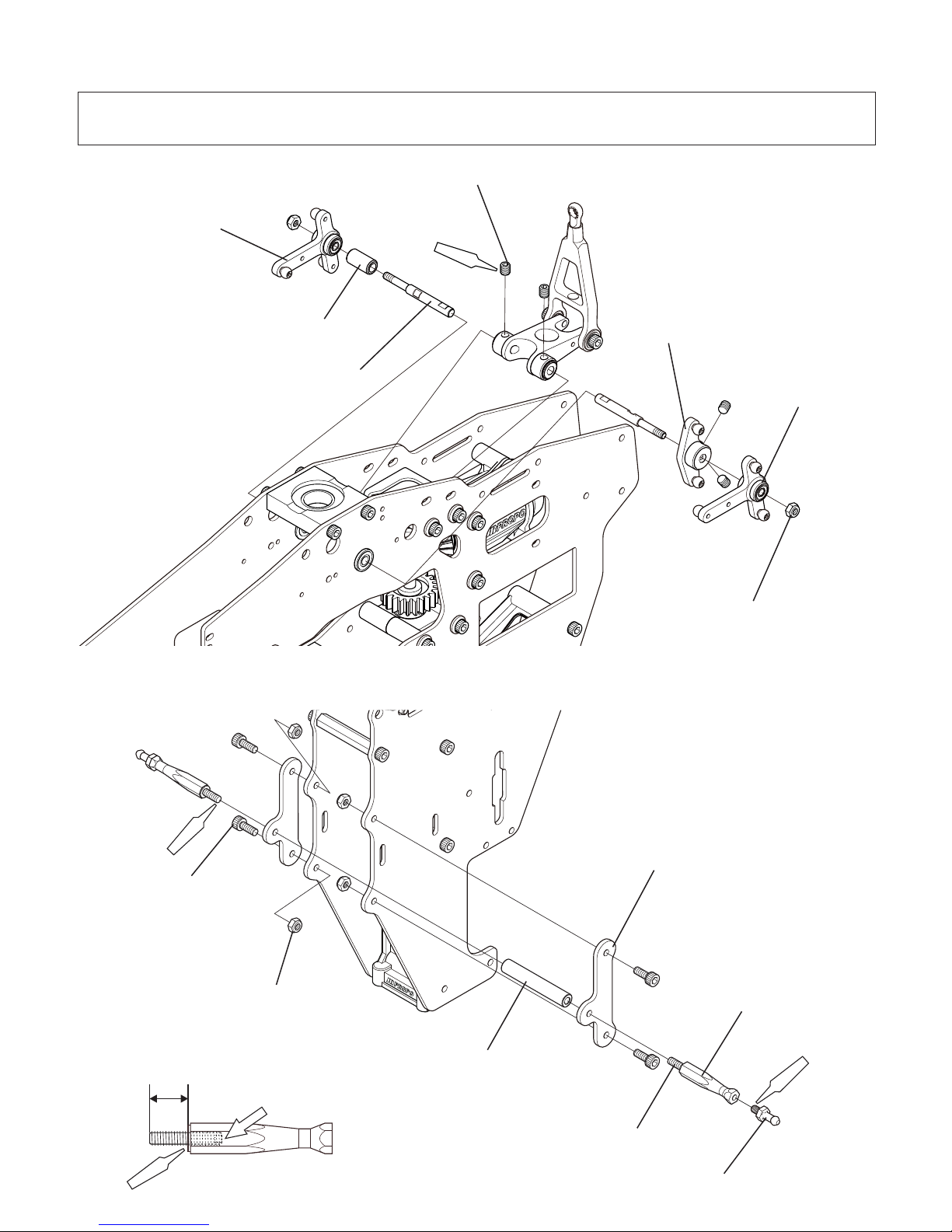

An adjustment hole for the alignment pin has been added to the T-arm.

There is no change to the assembly method.

1-4 T-ARM AND ELEVATOR ARM ASSEMBLY

1-5 SWASH CONTROL ARM ASSEMBLY

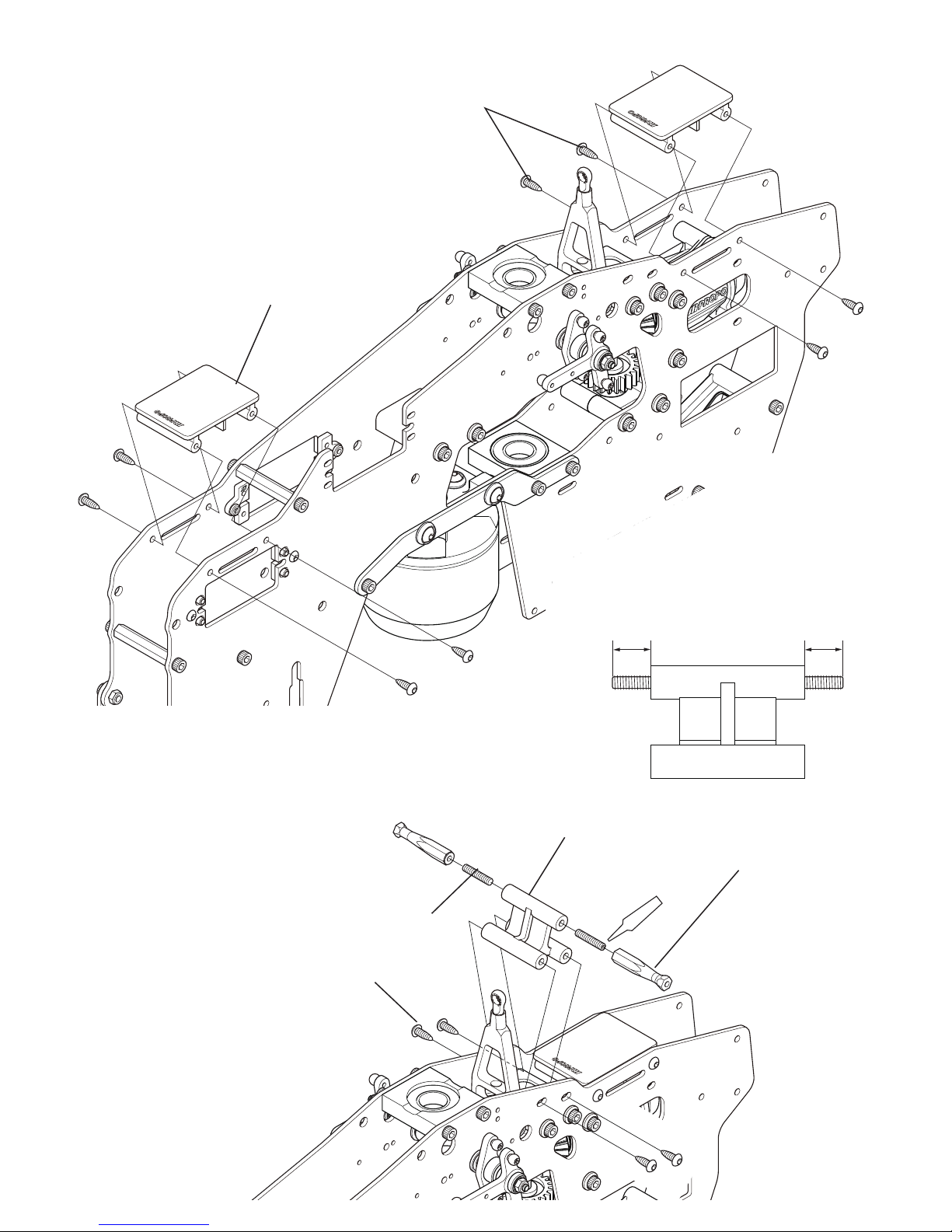

1-6 DRIVE GEAR ASSEMBLY

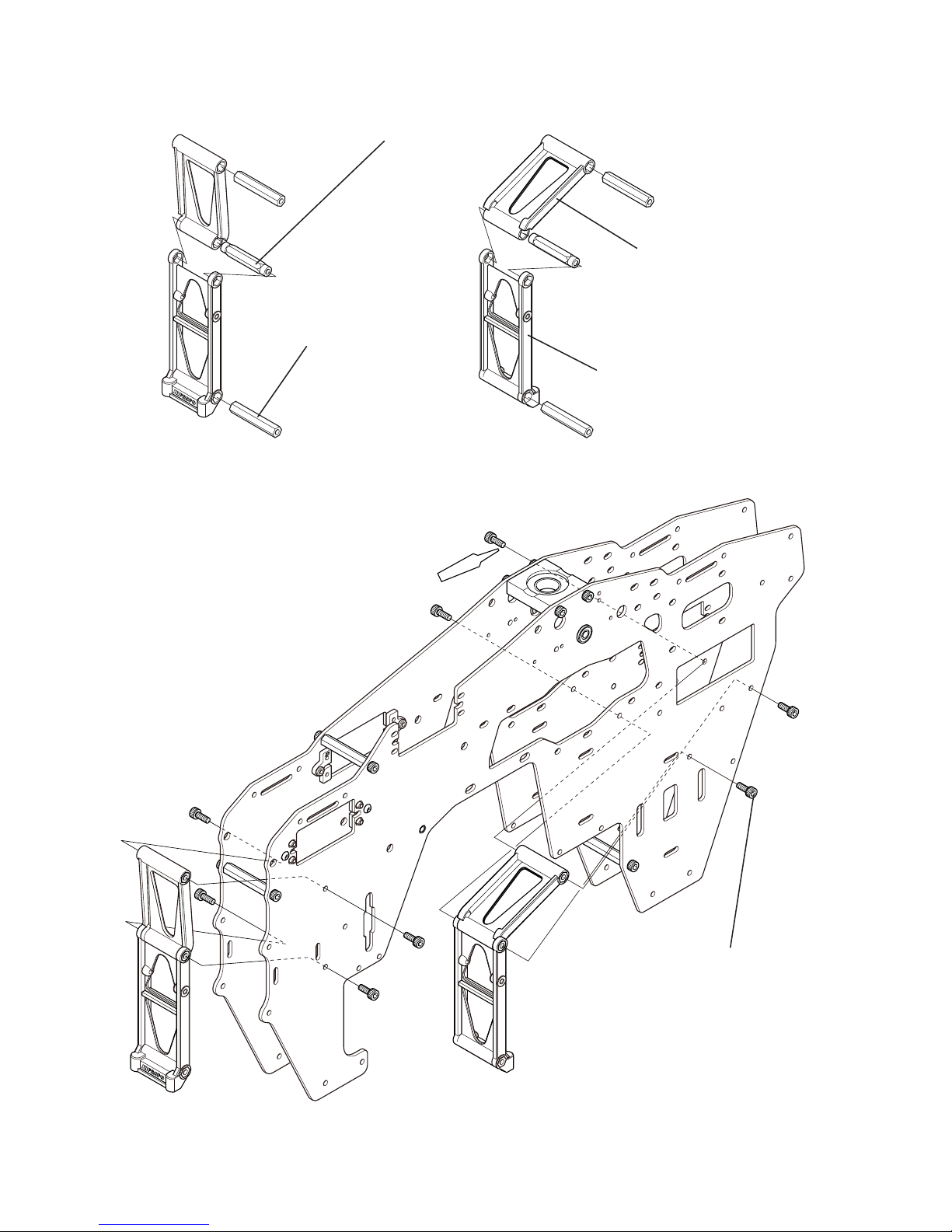

1-8 CARBON TOP TRAY ASSEMBLY

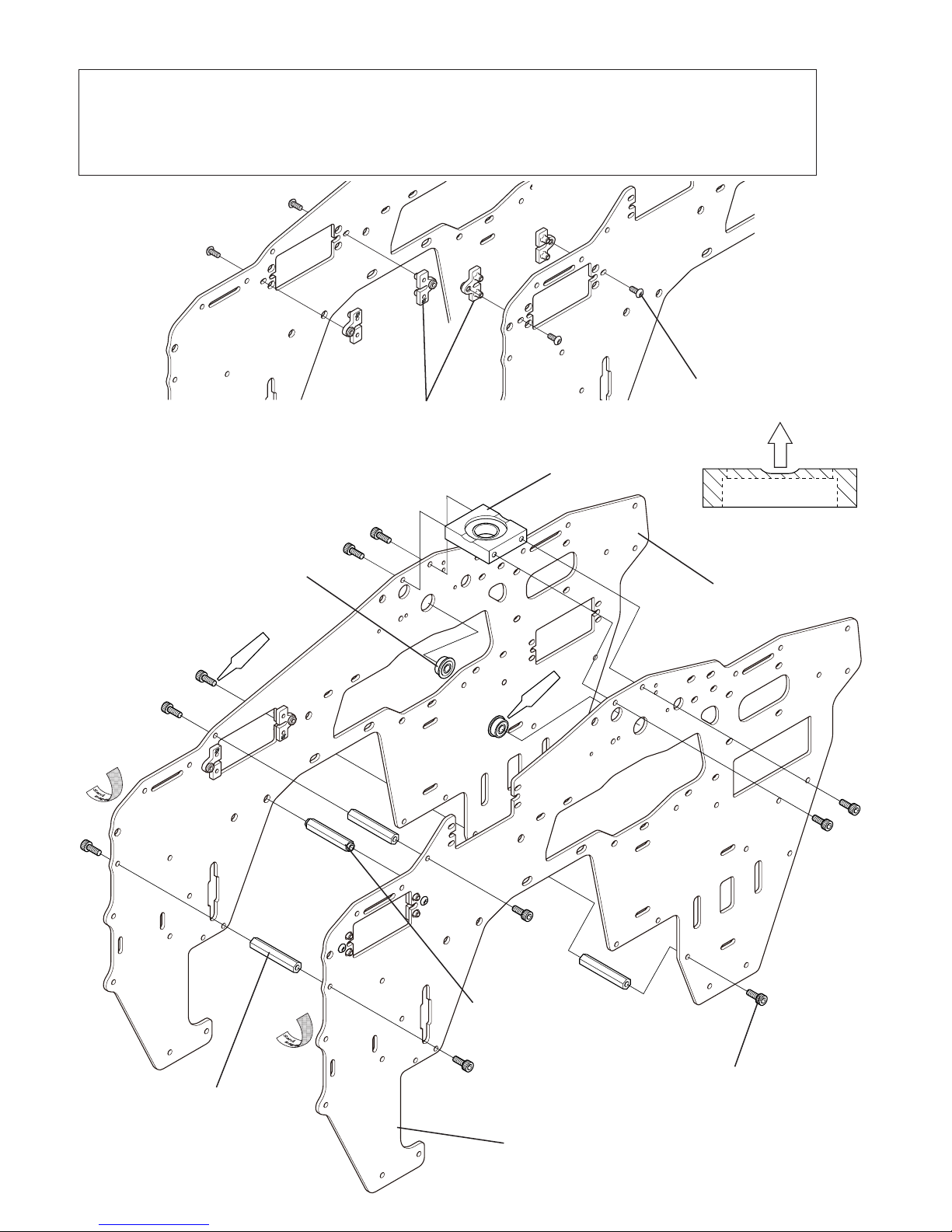

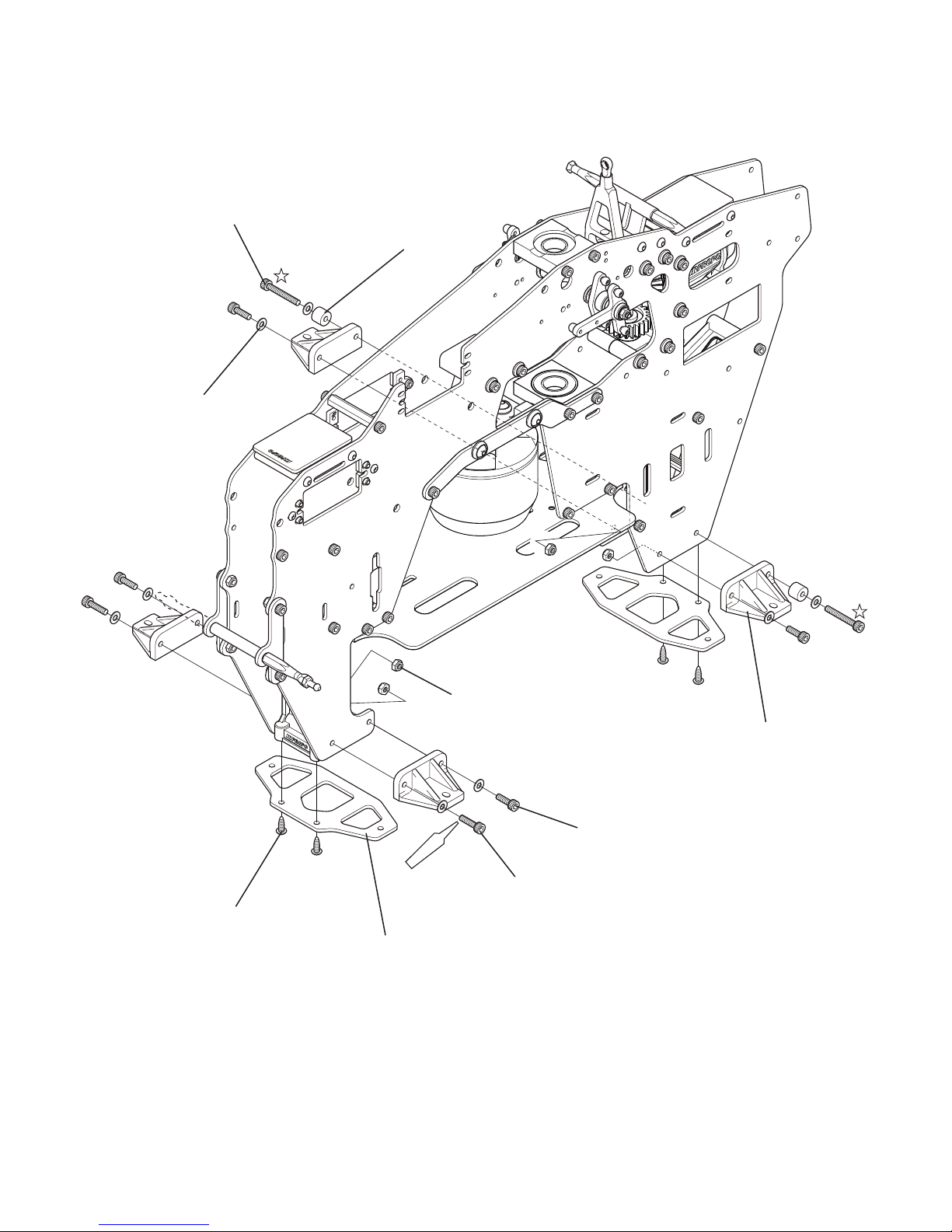

1-7 CARBON FRAME SUPPORT PLATE ASSEMBLY

1-9 FRONT TRAY OR BODY MOUNT PLATE ASSEMBLY

An adjustment hole for the alignment pin has been added to the Swash control base.

There is no change to the assembly method.

The drive gear thickness has been increased.

The side marked "T93" should face up when assembled.

This step has been deleted.

This step has been deleted.

This step has been deleted.

The body catch will be assembled in a later step.