INTRODUCTION ....................................................................................................................................................................... 4

KEY FEATURES.......................................................................................................................................................................... 4

PRE-ASSEMBLY WARNING ................................................................................................................................................... 5

RECOMMENDED RADIO SYSTEM ...................................................................................................................................... 5

ITEMS REQUIRED TO COMPLETE ASSEMBLY................................................................................................................. 6

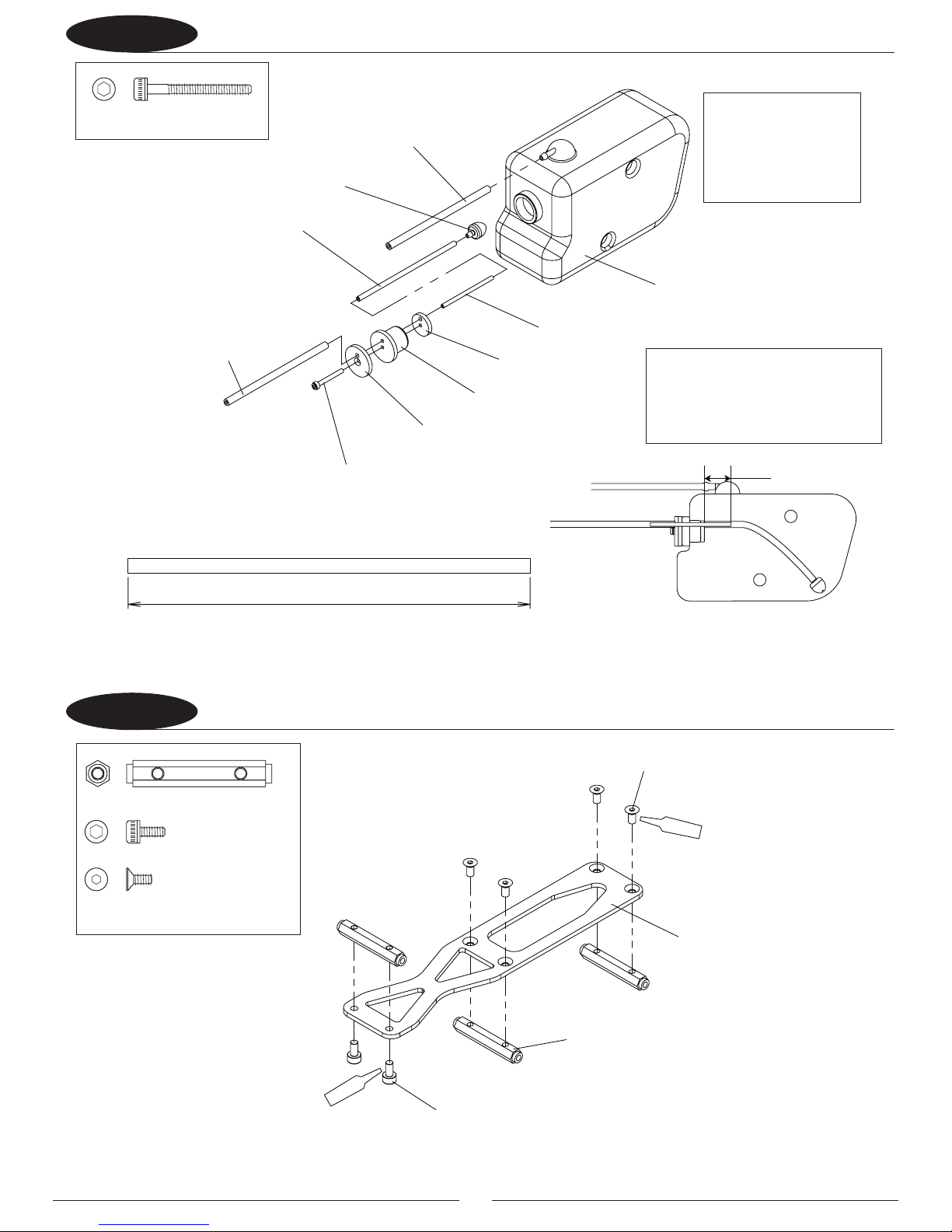

1-1 CLUTCH BELL/START SHAFT ASSEMBLY......................................................................................................... 7

1-2 BEVEL GEAR ASSEMBLY........................................................................................................................................ 7

1-3 TAIL DRIVE TRANSMISSION ASSEMBLY.......................................................................................................... 8

1-4 T-ARM LEVER ASSEMBLY..................................................................................................................................... 8

1-5 ELEVATOR A-ARM ASSEMBLY............................................................................................................................ 9

1-6 DOUBLE MAIN DRIVE GEAR ASSEMBLY.......................................................................................................... 9

1-7 FUEL TANK ASSEMBLY........................................................................................................................................10

1-8 FRAME SUPPORT ASSEMBLY ............................................................................................................................10

1-9 FRONT TRAY ASSEMBLY..................................................................................................................................... 11

2-1 MAIN FRAME ASSEMBLY 1 ................................................................................................................................ 12

2-2 MAIN FRAME ASSEMBLY 2 ................................................................................................................................13

2-3 MAIN FRAME ASSEMBLY 3 ................................................................................................................................14

2-4 CLUTCH BELL INSTALLATION .......................................................................................................................... 15

2-5 TAIL PINION UNIT INSTALLATION .................................................................................................................. 16

2-6 CCPM LEVERS INSTALLATION .........................................................................................................................17

2-7 FRONT BED INSTALLATION ..............................................................................................................................18

2-8 GYRO TRAY/BRACKET ATTACHMENT ........................................................................................................... 19

2-9 TANK FRAME ASSEMBLY ................................................................................................................................... 20

2-10 FUEL TANK INSTALLATION ............................................................................................................................... 21

2-11 LANDING STRUTS ADAPTER INSTALLATION ...............................................................................................22

2-12 LANDING GEAR INSTALLATION ......................................................................................................................23

3-1 MAIN SHAFT/MAIN DRIVE GEAR INSTALLATION ......................................................................................24

3-2 COOLING FAN/CLUTCH INSTALLATION ....................................................................................................... 25

3-3 ENGINE INSTALLATION ......................................................................................................................................26

3-4 COOLING FAN SHROUD INSTALLATION ...................................................................................................... 27

3-5 INSTALLATION OF THE MUFFLER/FUEL LINE CONNECTIONS .............................................................. 28

4-1 SWASHPLATE/WASHOUT INSTALLATION ................................................................................................... 29

4-2 MIXING ARM INSTALLATION ............................................................................................................................ 30

4-3 ROTOR HEAD ASSEMBLY ...................................................................................................................................31

4-4 SEESAW SHAFT INSTALLATION .......................................................................................................................32

4-5 ROTOR HEAD INSTALLATION ........................................................................................................................... 33

4-6 CONTROL ROD INSTALLATION ....................................................................................................................... 34

TABLE OF CONTENTS