5-1 TAIL DRIVE SHAFT ASSEMBLY...........................................................................................................................31

5-2 TAIL BOOM INSTALLATION...............................................................................................................................31

5-3 TAIL GEAR CASE INSTALLATION 1...................................................................................................................32

5-4 TAIL GEAR CASE INSTALLATION 2..................................................................................................................33

5-5 TAIL PITCH CONTROL LEVER INSTALLATION..............................................................................................34

5-6 TAIL CENTER HUB ASSEMBLY............................................................................................................................35

5-7 TAIL BLADE HOLDER ASSEMBLY......................................................................................................................36

5-8 TAIL BOOM BRACE ASSEMBLY..........................................................................................................................37

5-9 TAIL BOOM BRACE INSTALLATION.................................................................................................................37

5-10 TAIL BELL CRANK INSTALLATION....................................................................................................................38

5-11 TAIL CONTROL ROD ATTACHMENT................................................................................................................39

RADIO SYSTEM PREPARATION........................................................................................................................................40

UNDERSTANDING THE CCPM CONTROL SYSTEMS........................................................................................... 41–42

IMPORTANT CCPM PROGRAMMING DO’S AND DON’TS........................................................................................43

CCPM SOFTWARE INITIAL ADJUSTMENTS...................................................................................................................44

JR X9303 2.4 AND XP9303: PROGRAMMING........................................................................................................45–48

JR 7202 AND SPEKTRUM DX7: PROGRAMMING.................................................................................................49–52

SPEKTRUM DX6i SYSTEMS: PROGRAMMING........................................................................................................53–55

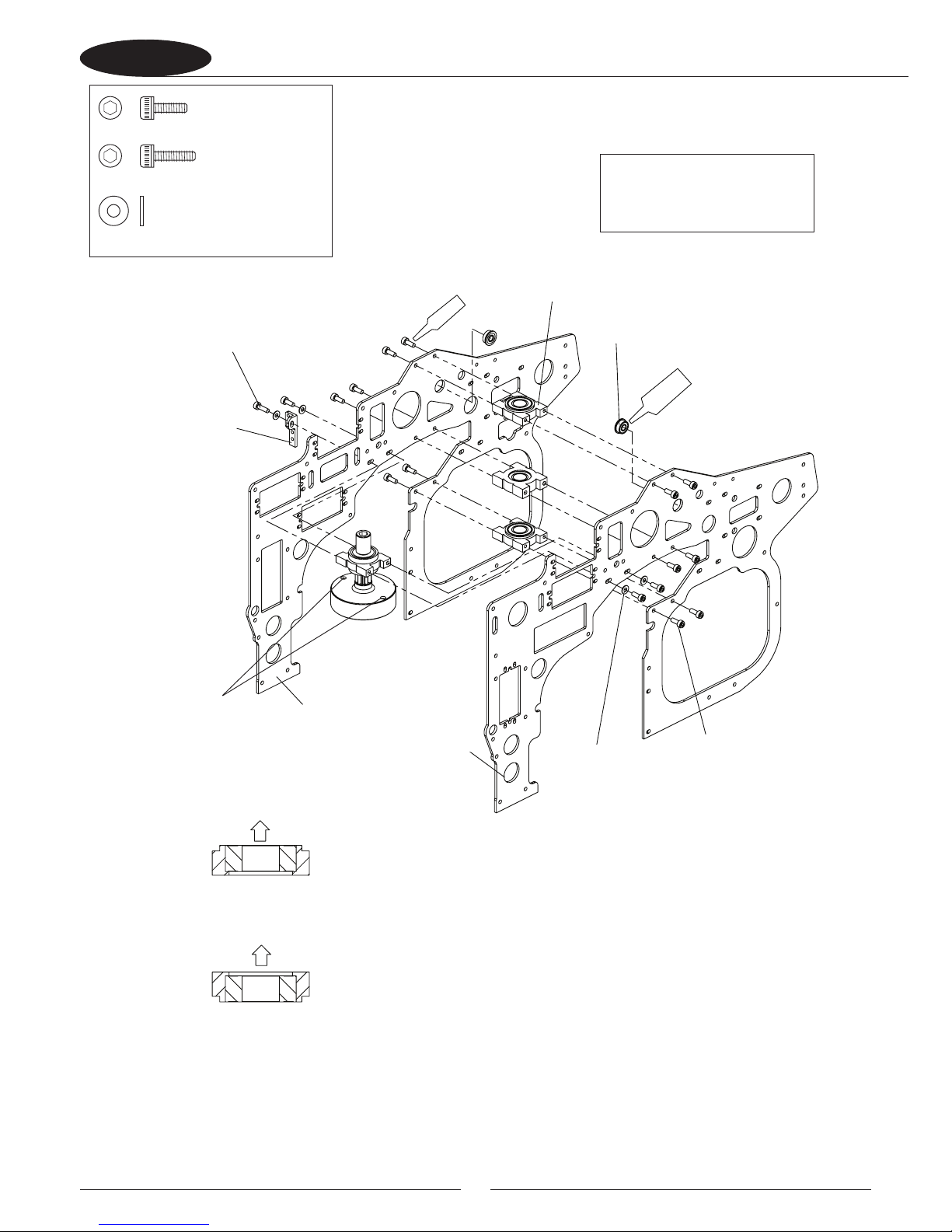

6-1 SERVO INSTALLATION 1.....................................................................................................................................56

6-2 SERVO INSTALLATION 2.....................................................................................................................................57

6-3 SERVO HORN INSTALLATION............................................................................................................................58

6-4 CCPM CONTROL ROD ASSEMBLY.................................................................................................................... 59

6-5 CCPM CONTROL ROD ATTACHMENT............................................................................................................ 60

6-6 CHECKING THE SWASHPLATE FOR LEVEL....................................................................................................61

6-7 TAIL CONTROL/THROTTLE LINKAGE ATTACHMENT.................................................................................62

6-8 GYRO/RECEIVER/BATTERY INSTALLATION..................................................................................................63

GENERAL RADIO SETUP INFORMATION................................................................................................................64–65

FINAL SERVO ADJUSTMENT AND RADIO SETUP........................................................................................................ 66

PITCH RANGE AND CURVE SETTINGS.............................................................................................................................. 67

7-1 BODY/MUFFLER ATTACHMENT.......................................................................................................................68

FINAL PREFLIGHT CHECK...................................................................................................................................................69

BLADE TRACKING ADJUSTMENT..................................................................................................................................... 69

BLADE TRACKING IDENTIFICATION................................................................................................................................70

GENERAL MAINTENANCE...................................................................................................................................................71

REPLACEMENT PARTS LISTING.................................................................................................................................. 72–93

WARRANTY INFORMATION........................................................................................................................................94–95