ii

CONTENTS

!. CAUTIONS BEFORE OPERATION ...............................................................................1

Precautions for use................................................................................................................................... 1

@. CONFIGURATION OF THE MACHINE..........................................................................2

#. OVERVIEW.....................................................................................................................3

1. Features ................................................................................................................................................. 3

2. Specications ........................................................................................................................................ 3

$. INSTALLATION ..............................................................................................................4

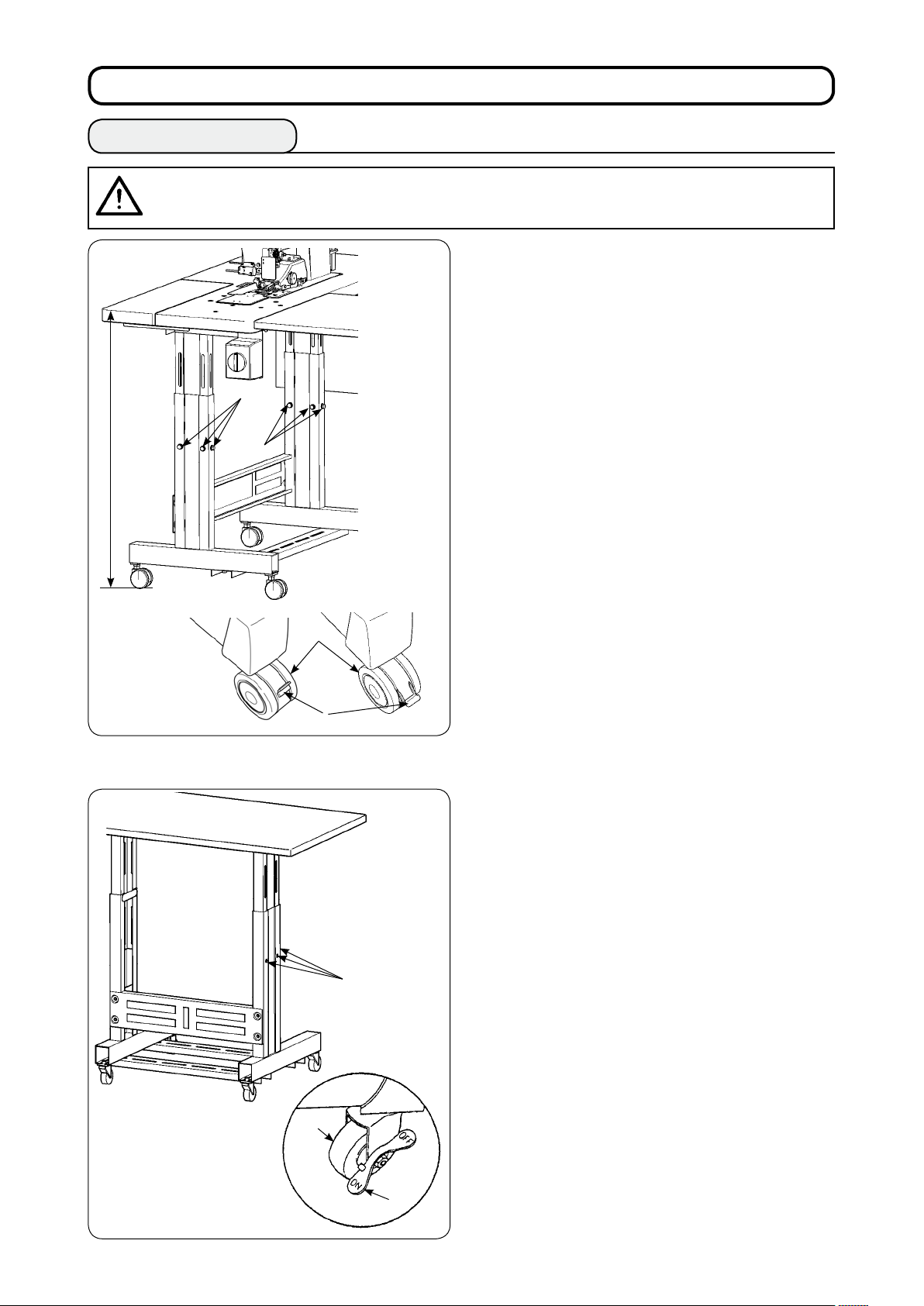

1. Table height............................................................................................................................................ 4

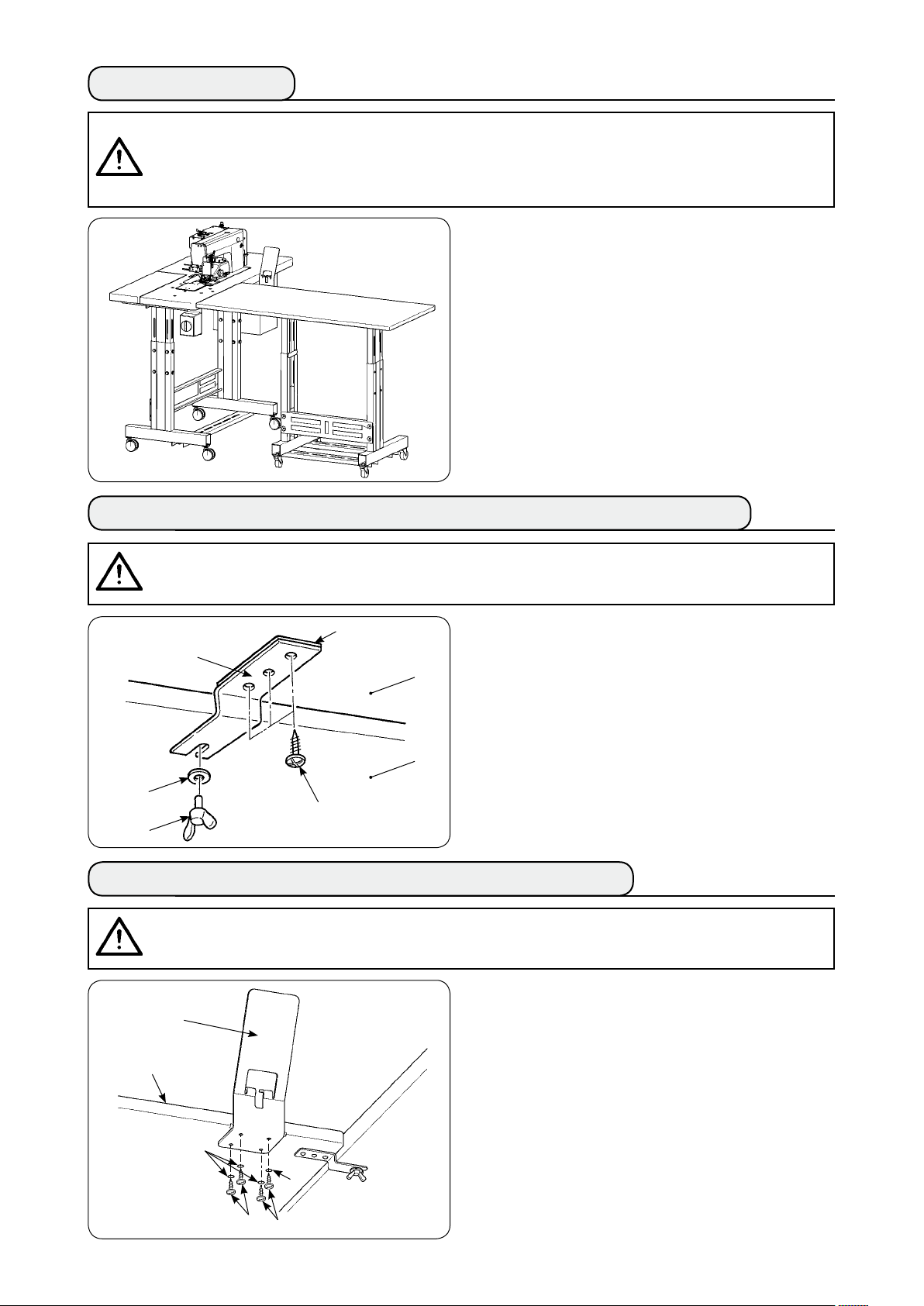

2. Auxiliary table ........................................................................................................................................ 5

3. Assembling the sewing machine table and auxiliary table ............................................................... 5

4. Installing the operation panel mounting plate.................................................................................... 5

5. Connecting the operation panel........................................................................................................... 6

6. Lubrication............................................................................................................................................. 7

7. Installing the thread stand.................................................................................................................... 7

8. Removing the covers ............................................................................................................................ 8

9. Threading the machine head................................................................................................................ 9

10. Adjusting the stitch length ............................................................................................................... 10

11. Fitting a needle .................................................................................................................................. 10

12. Loading the bobbin ........................................................................................................................... 11

13. Connecting and adjusting the air source........................................................................................ 11

%. INSTALLING THE OPTIONAL DEVICES ....................................................................12

1. Installing the 2-pedal unit ................................................................................................................... 12

2. Installing the stacker........................................................................................................................... 13

3. Installing and adjusting the bobbin winder ...................................................................................... 21

4. Assembling the thread breakage detecting device and setting of the operation panel ............... 23

5. Installing the bobbin thread remaining amount detecting device.................................................. 26

^. HOW TO USE THE OPERATION PANEL....................................................................33

1. Explanation about switches on the operation panel........................................................................ 33

2. Basic operation of the sewing machine............................................................................................ 35

3. Selecting a pattern .............................................................................................................................. 37

4. Winding a bobbin ................................................................................................................................ 38

5. Using the counter................................................................................................................................ 40

6. Changing the sewing data.................................................................................................................. 41

7. Using the initial value pattern ............................................................................................................ 42

8. Sewing data list ................................................................................................................................... 43

9. Copying a sewing pattern................................................................................................................... 50

10. Using the PATTERN REGISTRATION key........................................................................................ 51

11. Using the PARAMETER REGISTRATION key.................................................................................. 52

12. Performing the cycle sewing............................................................................................................ 53

13. Changing the memory switch data.................................................................................................. 55

14. List of memory switch data .............................................................................................................. 56

15. Setting the upper shirring................................................................................................................. 60

16. Setting the manipulator pressure .................................................................................................... 61

17. Using the teaching ............................................................................................................................ 62

18. Correcting the bottom feed amount readout potentiometer ......................................................... 64