Be sure to observe the following to protect against a re, electrical shock, injury or damaged components.

* Be sure to unplug the machine before disassembly, assembly or adjustment of the machine.

* Be sure to carefully prevent electric cords from being caught, coated surfaces from being damaged as well

as wrong wiring during assembly.

* Be sure to use the proper genuine parts when changing any of the machine parts.

CAUTION:

CONTENTS

[1] Specications of HZL-X Series ............................................................................1

[2] Search by trouble (related to mechanical components) ...................................3

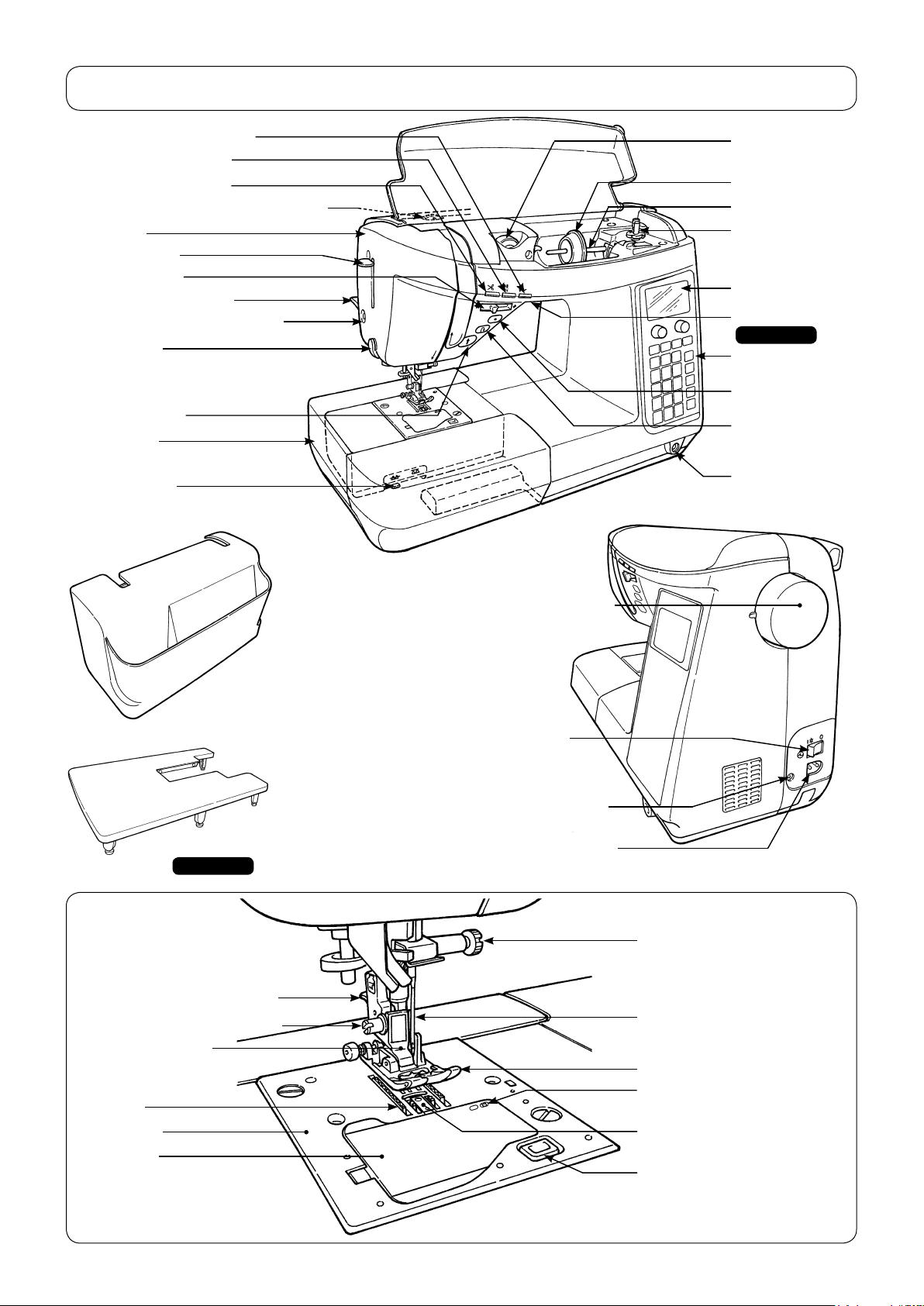

[3] Principal parts .......................................................................................................4

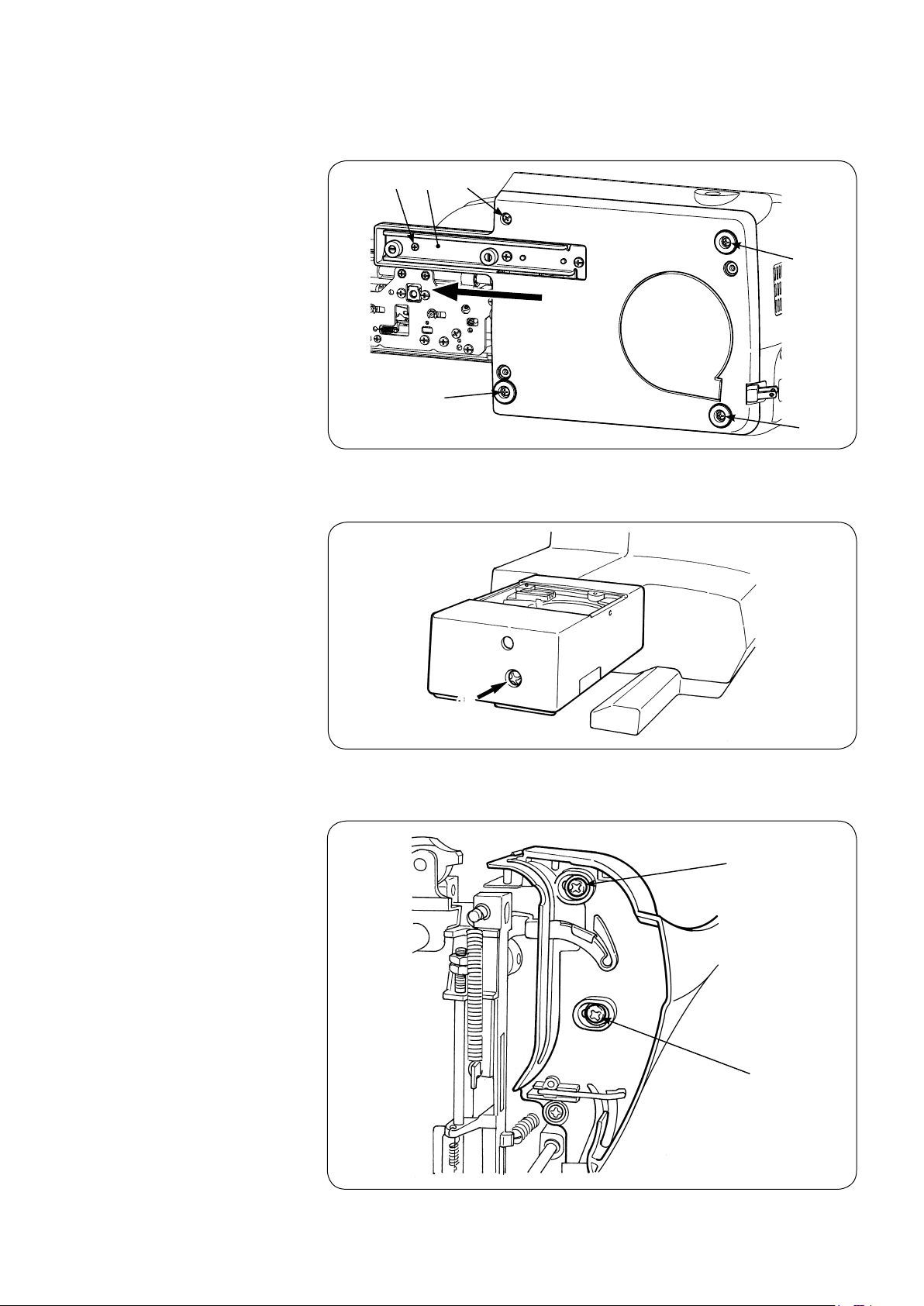

[4] Disassembling the machine covers ....................................................................5

[5] PCB connection diagram .....................................................................................9

[6] Adjustment ..........................................................................................................13

6-1 Adjusting the needle bar height ................................................................13

6-2 Adjusting the needle entry point ...............................................................14

6-3 Feed dog height ..........................................................................................14

6-4 Timing belt ...................................................................................................15

6-5 Feed timing ..................................................................................................15

6-6 Timing between the needle and the hook .................................................16

6-7 Clearance between the needle and the blade point of hook ...................17

6-8 Position of the hook rotation stopper plate .............................................18

6-9 Adjusting the bobbin thread tension ........................................................18

6-10 Adjusting the disk opening amount ........................................................19

6-10-1 Adjusting the thread tension release adjusting plate ................................19

6-10-2 Pretension disk opening amount .................................................................19

6-10-3 Tension disk opening amount ......................................................................20

6-10-4 Base tension opening amount .....................................................................20

6-11 Adjusting the needle thread tension .......................................................21

6-12 Vertical position of the needle threading hook ......................................22

6-13 Adjusting the auxiliary hook height ........................................................23

6-14 Adjusting the opening amount of auxiliary hook ...................................24

6-15 Adjusting the presser bar height .............................................................24

6-16 Motor belt ...................................................................................................25

6-17 Automatic thread trimming ......................................................................26

6-17-1 Lateral position of the thread trimming mechanism base .........................26

6-17-2 Phase of the catching unit driving cam .......................................................27

6-17-3 Replacing the thread trimming blade ..........................................................28

6-18 Longitudinal feed ......................................................................................29

6-19 Knee lifting wire ........................................................................................30

6-20 Automatic presser foot lifting ..................................................................31

6-20-1 Auto-lifter cam lever ......................................................................................31

6-20-2 Presser-lifter position sensor .......................................................................32

6-20-3 Adjusting the height of the presser foot when it is lifted ...........................33

6-21 Straight stitch slide plate .........................................................................35

6-21-1 Adjusting the position of the straight stitch slide plate .............................35

6-21-2 Straight stitch slide plate sensor PCB .........................................................36

6-22 Service mode .............................................................................................37

6-22-1 Service mode screen .....................................................................................37

6-22-2 Service-mode items and descriptions .........................................................37