SAFETY PRECAUTIONS

DANGER

To prevent from receiving an electric shock, always turn off a power switch

and

unplug power supply

when opening a control

box, and then open after ten minutes passes.

CAUTION

Please do not operate the sewing machine under the following conditions.

In the ambient temperature of 35 degrees (95°F) or more than 35 degrees, or the

temperature of 5 degrees or less than 5 degrees (41°F).

In the ambient temperature of 55 degrees (131°F) or more than 55 degrees, or the

temperature of -10 degrees or less than -10 degrees (18°F) during transportation.

In the relative humidity exceeding 85% or less than 45%.

In the open-air place or the location that receives direct sunlight.

In the place near heat sources such as heating devices.

In the atmosphere filled with dust, explosive gas, or corrosive gas.

In the place where the

fluctuation in the power voltage of 10% or more than 10%, or the power

voltage of -10% or less than -10% of the fixed power voltage.

In the place where the power source cannot supply enough voltage to keep the motor running.

(9)

In the place filled with strong electric noises such as high-frequency welders.

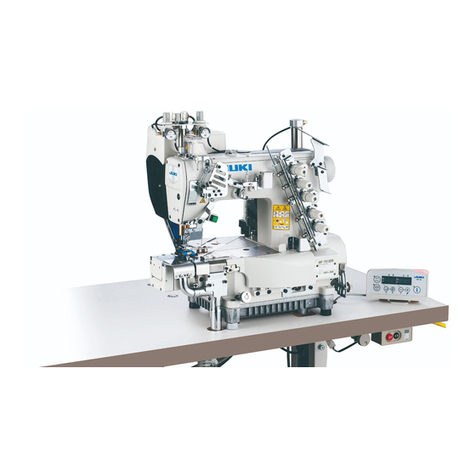

Please have some specialists, who have enough experience for the sewing machine installations,

install the sewing machine.

Please have a qualified electrician perform necessary electric wiring.

Please do not operate until the sewing machine is repaired when any damage or fault is found on

the sewing machine at the installation.

Please do not refurbish the sewing machine.

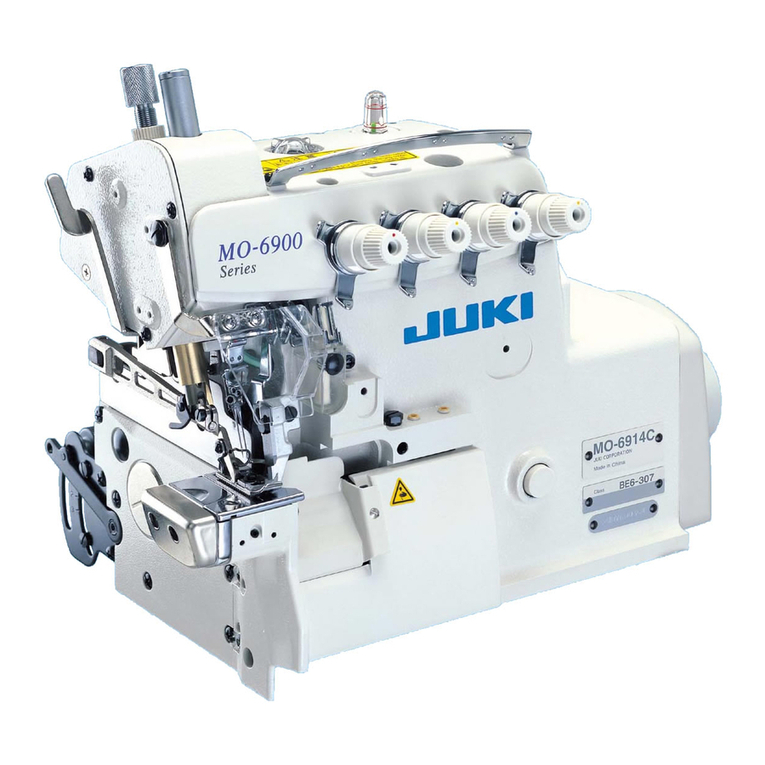

The sewing machine is heavy. For the safety, please make sure to

install the sewing machine head

by more than one person.

Please make sure to fit the safety protective equipment (the motor cover or the others) and the

accessory protective equipment (the eye guard) that removed temporarily for installation.