- 4 -

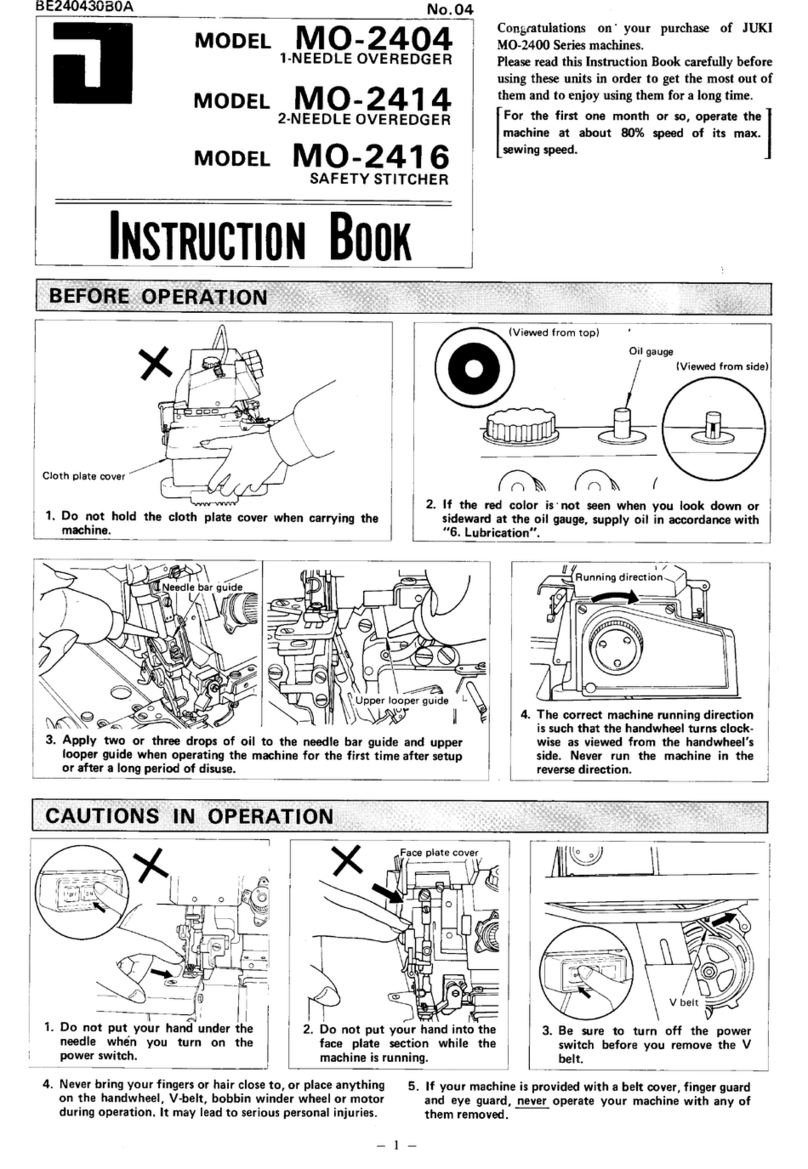

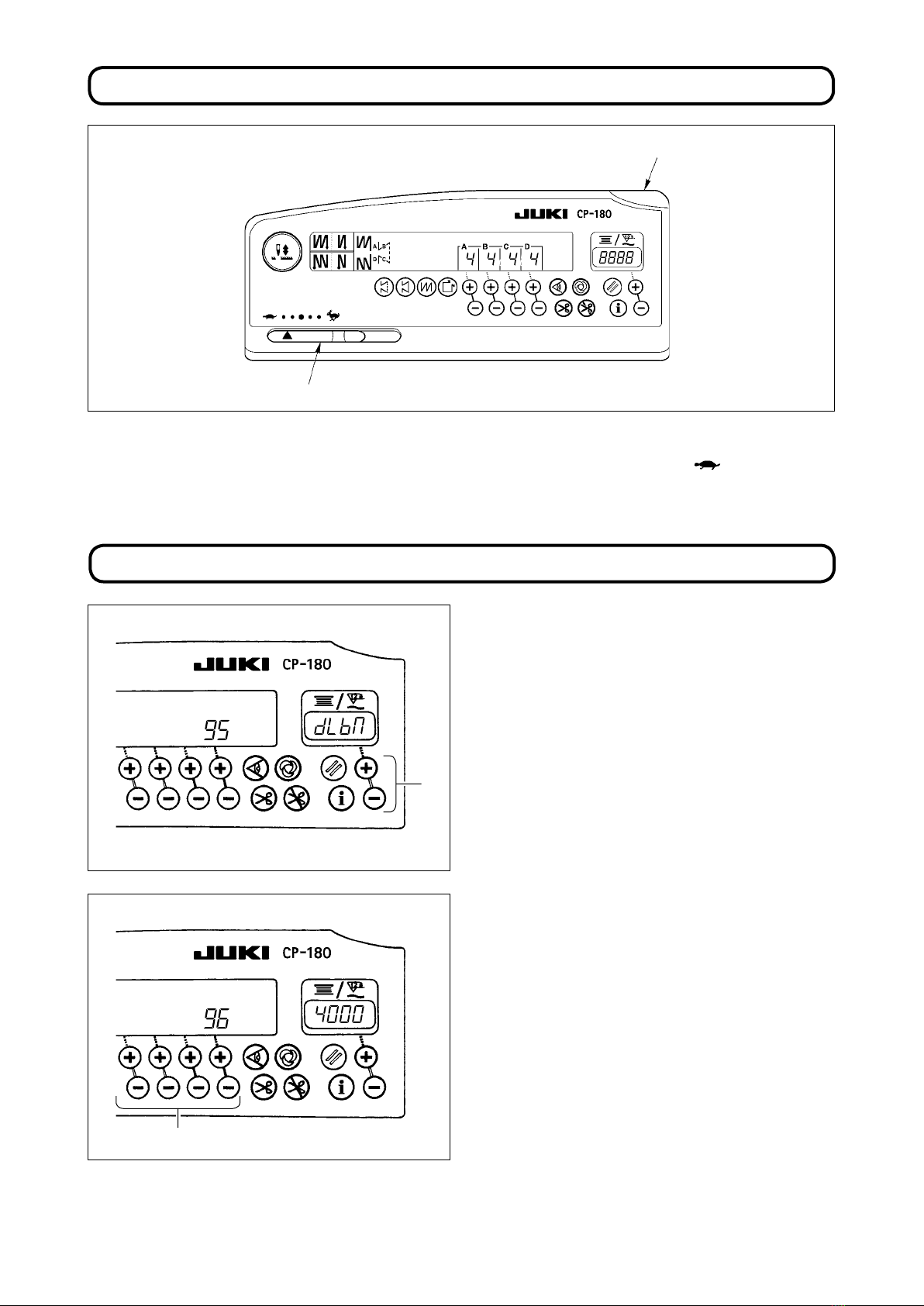

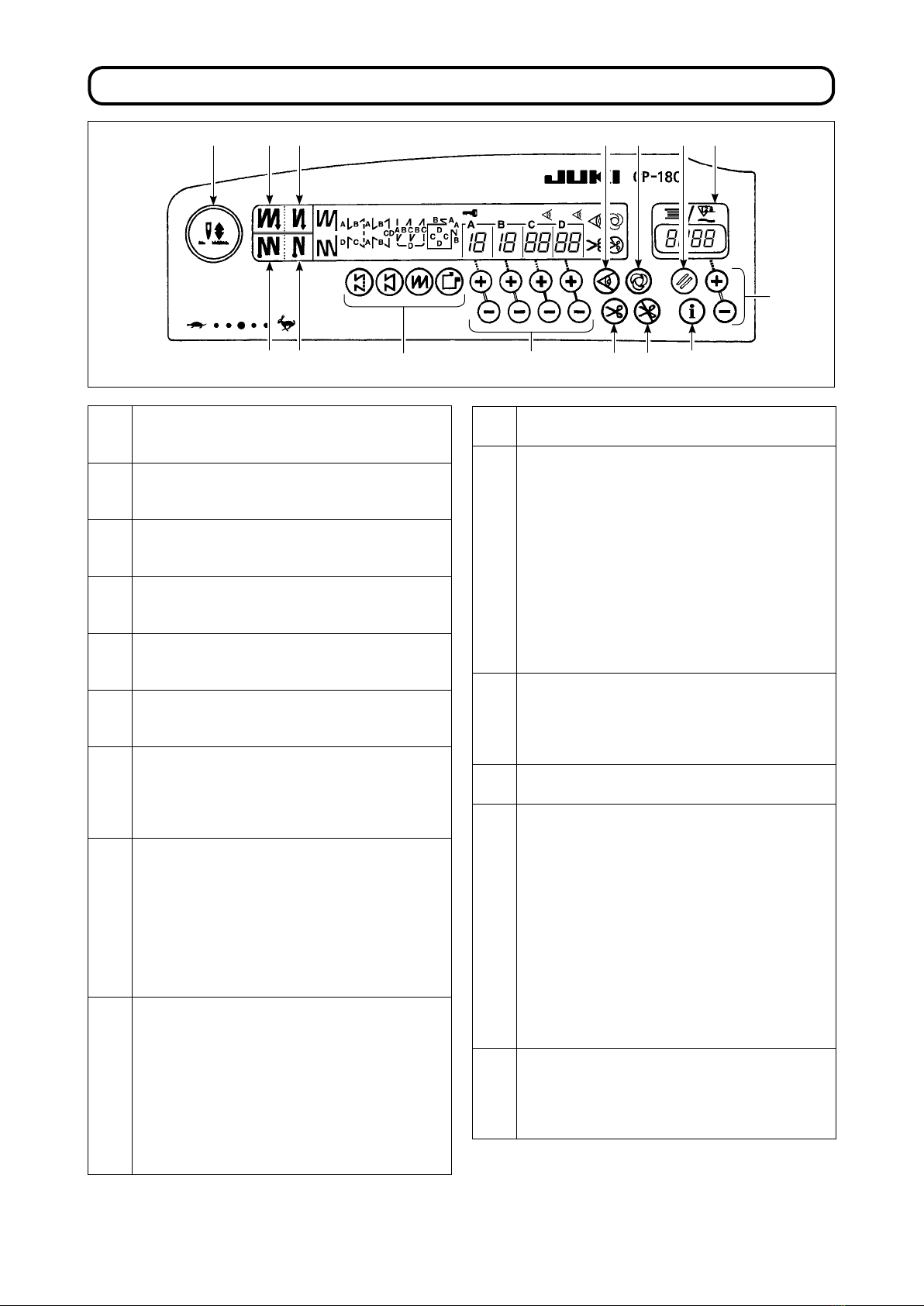

6. EXPLANATION OF THE CONTROL PANEL

1Pattern selector switch

• Used for selecting a pattern from among the

four different patterns.

2Double reverse stitching (for start) switch

• Used for turning ON/OFF the double reverse

stitching for start.

3Double reverse stitching (for end) switch

• Used for turning ON/OFF the double reverse

stitching for end.

4Automatic reverse stitching (for start) switch

• Used for turning ON/OFF the automatic

reverse stitching for start.

5Automatic reverse stitching (for end) switch

• Used for turning ON/OFF the automatic

reverse stitching for end.

6Switches for setting the number of stitches

• Used for setting the number of stitches to be

sewn in processes A through D.

7Material edge sensor ON/OFF switch

• Rendered effective when the material edge

sensor is installed on the machine.

• Used for setting whether or not the material

edge sensor is used during sewing.

8One-shot automatic stitching switch

• Rendered effective when the material edge

sensor is installed on the machine or when

the sewing machine is operated under the

constant-dimension stitching mode.

• Start the sewing machine with this switch, and

the sewing machine will run automatically until

the material edge is detected or the end of a

constant-dimension stitching is reached.

9Automatic thread trimming switch

• Rendered effective when the material edge

sensor is installed on the machine or when

the sewing machine is operated under the

constant-dimension stitching mode.

• Even keep depressing the front part of the

pedal, the sensor can detect the material

edge, or after the completion of the constant-

dimension stitching mode, the machine will

automatically perform thread trimming.

!0 Thread trimming prohibition switch

•

Used for prohibiting thread trimming at any occasion.

!1

Bobbin thread counter/thread trimming counter

• Bobbin thread counter/thread trimming counter

can be changed over by the function of the control

box main body.

Bobbin thread counter :

• Indicates the amount of bobbin thread while

counting it by subtracting from the set value.

• When the bobbin thread remaining amount

detecting device is installed on the machine, the

counter indicates the number of times of detecting.

Thread trimming counter :

• Every time thread trimming is performed, the

counter value is added.

!2 Bobbin counter reset switch

• Used for returning the value shown on the

bobbin thread counter to the initial value.

• When the thread trimming counter is selected,

it is reset to [0].

!3 Bobbin thread amount setting switch

• Used for setting the amount of bobbin thread.

!4

Needle up/down compensation switch

• Used for performing needle up/down

compensation stitching.

[Changeover selection of needle bar stop position

when the pedal is in its neutral position]

• Pressing the needle up/down compensation

switch, turn ON the power to the machine, and

the needle bar stop position when the pedal is

in its neutral position is changed over to down

position/up position.

• Conrmation of the stop position can be

performed at the front cover of the control box.

When up position stop is specied : " nP UP "

When down stop position is specied : " nP Lo "

!5 Information switch

• Used for calling the production support

function and calling the one-touch setting

(by keeping the switch held pressed for one

second.)

!4 2 4 8 !1

3 5 9!5

61

!3

7!2

!0