CONTENTS

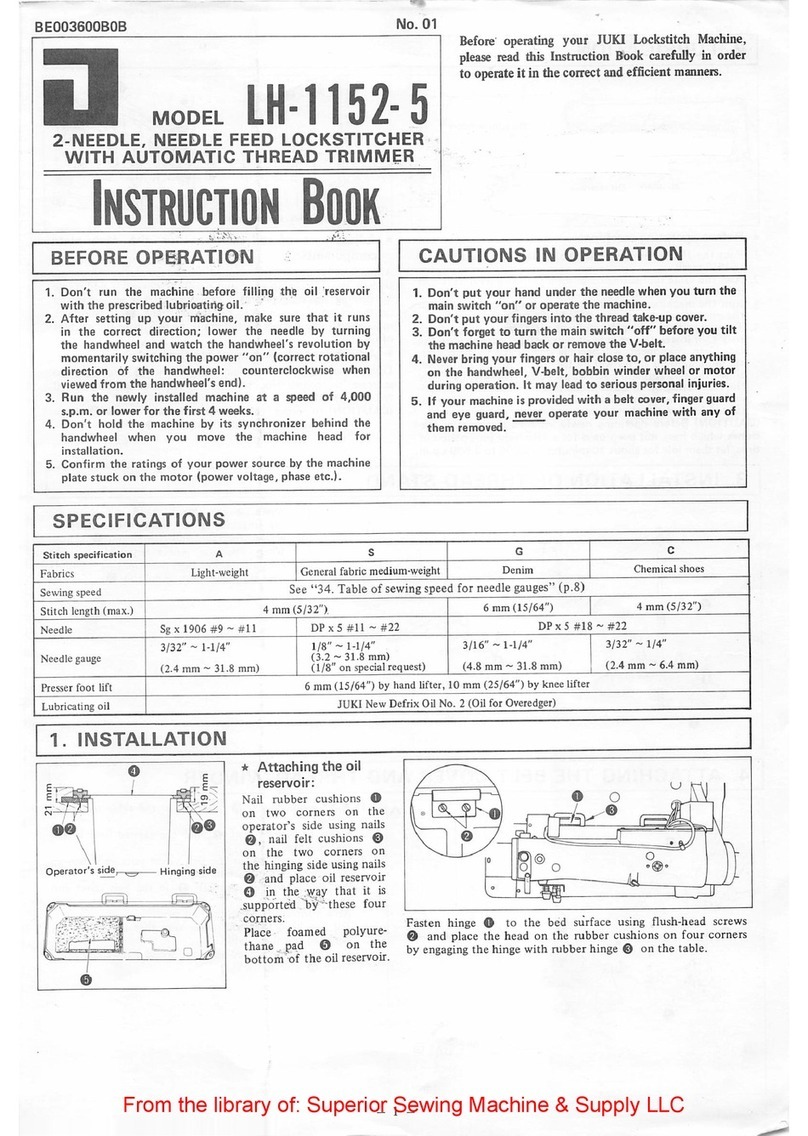

1. SPECIFICATIONS....................................................................................................... 1

2. STANDARD ADJUSTMENT ....................................................................................... 3

1) Position of the needle entry..........................................................................................................................................3

2) Longitudinal position of the feed dog ...........................................................................................................................3

3) Lateral position of the feed dog ....................................................................................................................................5

4) Height of the feed dog ..................................................................................................................................................5

5) Height of the hook ........................................................................................................................................................7

6) Adjusting the inner hook guide .....................................................................................................................................7

7) Needle-to-hook timing ..................................................................................................................................................9

8) Presser lifter lever ......................................................................................................................................................11

9) Knee lifter ...................................................................................................................................................................11

10) Main shaft-to-hook driving shaft timing ....................................................................................................................13

11) Feed drive eccentric cam timing ..............................................................................................................................13

12) Installing position of the alternate vertical movement amount detecting switch.......................................................15

13) Top feed cam timing.................................................................................................................................................17

14) Feed movement .......................................................................................................................................................17

Ⅰ. Amount of alternate vertical movement of walking foot and presser foot ............................................................17

◯In case of the machine without thread trimmer .............................................................................................17

◯In case of the machine with thread trimmer ..................................................................................................19

Ⅱ. Amount of alternate movement of walking foot and presser foot ........................................................................19

15) Needle sway (Optional selection of LU-1510 and LU-1510-7 only) .........................................................................21

16) Stitch length of normal/reverse feed ........................................................................................................................21

17) Balancer ...................................................................................................................................................................21

18) Position of the reverse feed control lever .................................................................................................................23

19) Safety clutch.............................................................................................................................................................23

20) Lubrication................................................................................................................................................................25

3. STANDARD ADJUSTMENT OF THE ADDITIONAL DEVICES (LU-1510-7)........... 29

(1) Thread trimmer device .................................................................................................. 29

1) Position of the counter knife and the clamp spring ....................................................................................................29

2) Position of the counter knife base ..............................................................................................................................29

3) Vertical position of the moving knife...........................................................................................................................31

4) Adjusting the knife pressure .......................................................................................................................................31

5) Thread trimmer solenoid ............................................................................................................................................33

6) Thread trimmer cam ...................................................................................................................................................33

7) Thread trimmer cam timing ........................................................................................................................................35

8) Connecting the driving arm and the thread trimmer roller arm...................................................................................35

4. INSTALLAION OF THE OPTIONAL PARTS ............................................................ 37

(1) Automatic reverse feed device..................................................................................... 37

1) Removing the side plate.............................................................................................................................................37

2) Removing the reverse feed control lever ...................................................................................................................37

3) Installing the reverse feed link hinge screw ...............................................................................................................37

4) Installing the reverse feed control lever .....................................................................................................................39

5) Installing the automatic reverse feed device ..............................................................................................................39

6) Installing the touch-back switch .................................................................................................................................41

7) Installing the pneumatic components .........................................................................................................................41

(2) Automatic presser foot lifter......................................................................................... 45

1) Assembling the automatic presser foot lifter ..............................................................................................................45

2) Installing the pneumatic device components .............................................................................................................47

5. PORTION TO WHICH LOCKTITE IS APPLIED........................................................ 49

6. SELECTIVE PARTS AND CONSUMABLE PARTS ................................................. 50

7. ENGRAVED MARKER DOTS ON THE HANDWHEEL ............................................ 51

8. PIPING DIAGRAM (LU-1510 AND LU-1510-7) ........................................................ 51

9. TABLE OF TROUBLES IN SEWING AND CORRECTIVE MEASURES ................. 52

10. TRABLE OF TROUBLES IN THREAD TRIMMING AND

CORRECTIVE MAESURES .................................................................................... 56