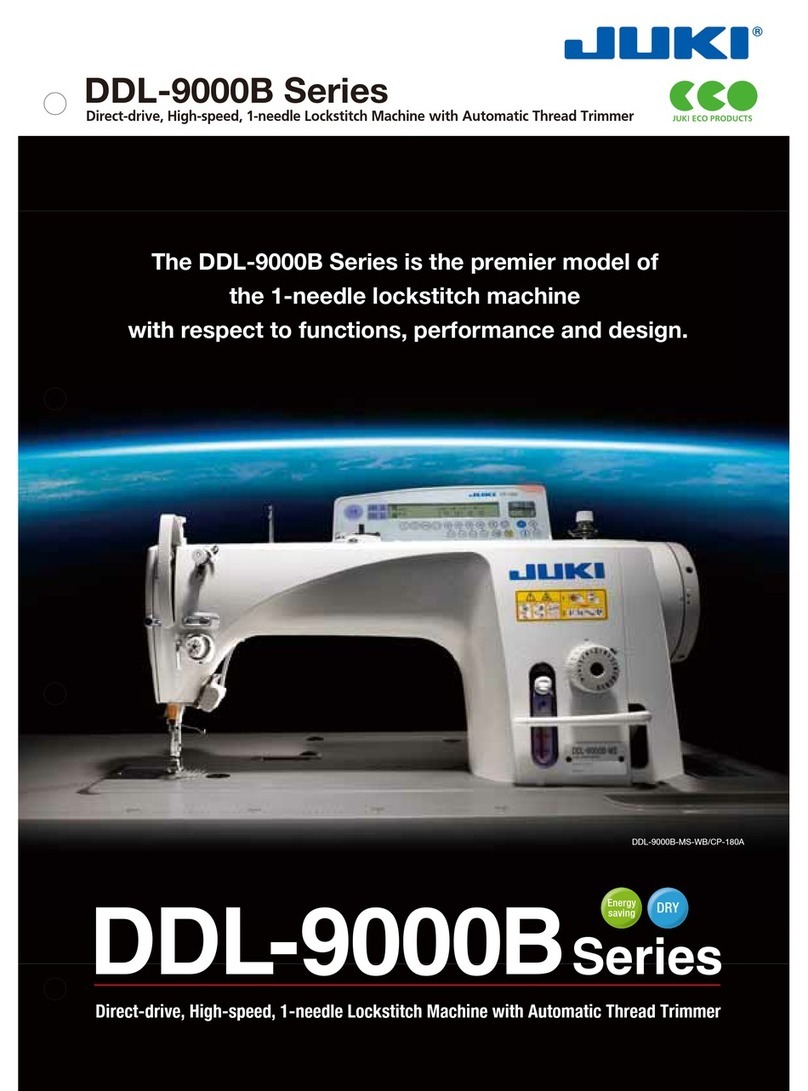

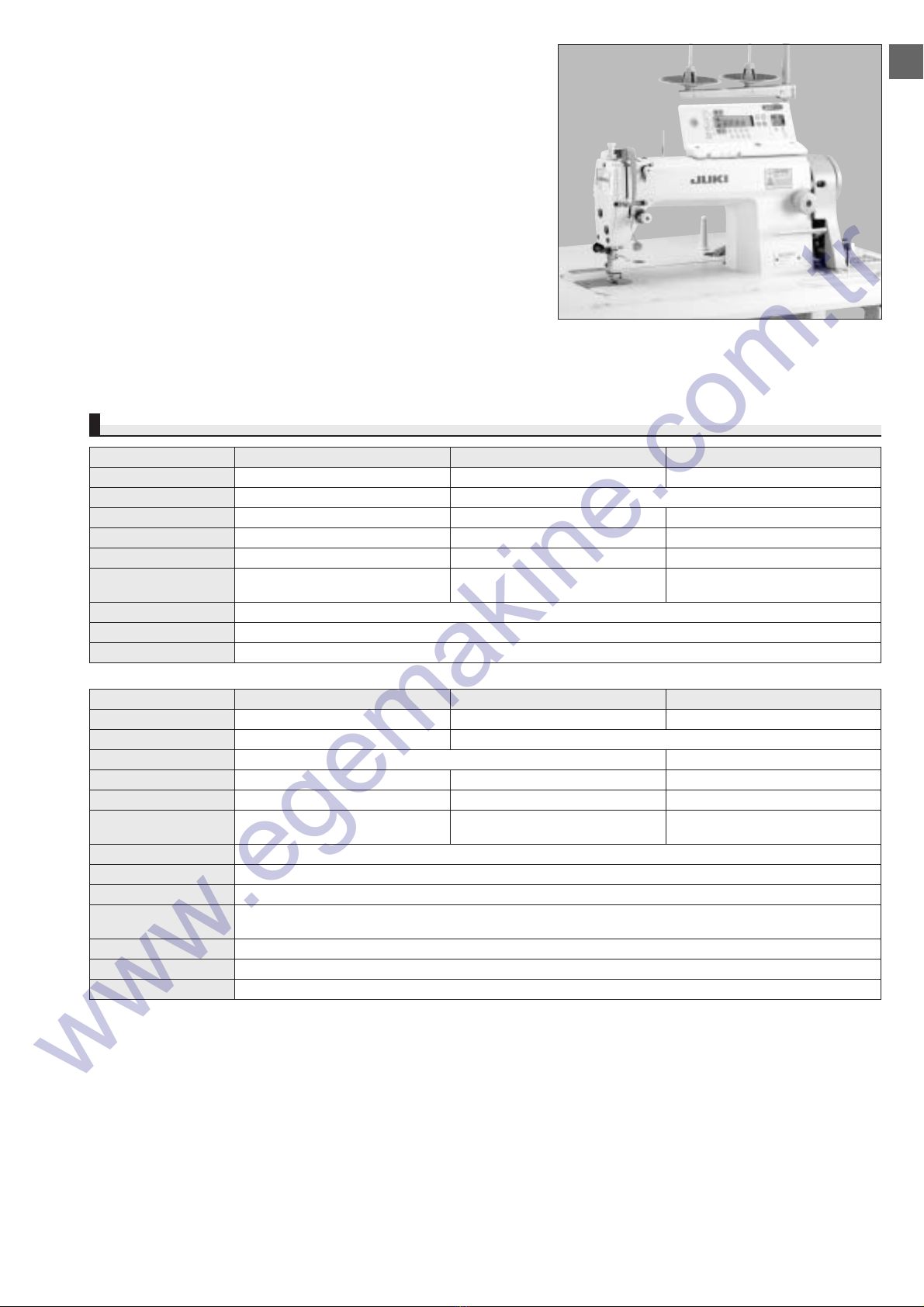

DDL-9000 (September, 2003) 1/2

DDL-9000DS-WB/CP-160D

●With its newly developed large machine head, the DDL-9000

dramatically upgrades seam quality and increases efficiency.

●The DDL-9000 incorporates a direct-drive system (DD system)

that offers quick start-up, upgraded stop accuracy, excellent

responsiveness, and a stronger needle thrust for faster,

better penetration into the material.

●Designed without an oil pan, the machine offers improved

maintainability with easy removal of dust and lint.

DDL-9000

Direct-drive, High-speed, 1-needle, LockstitchMachine

with AutomaticThreadTrimmer

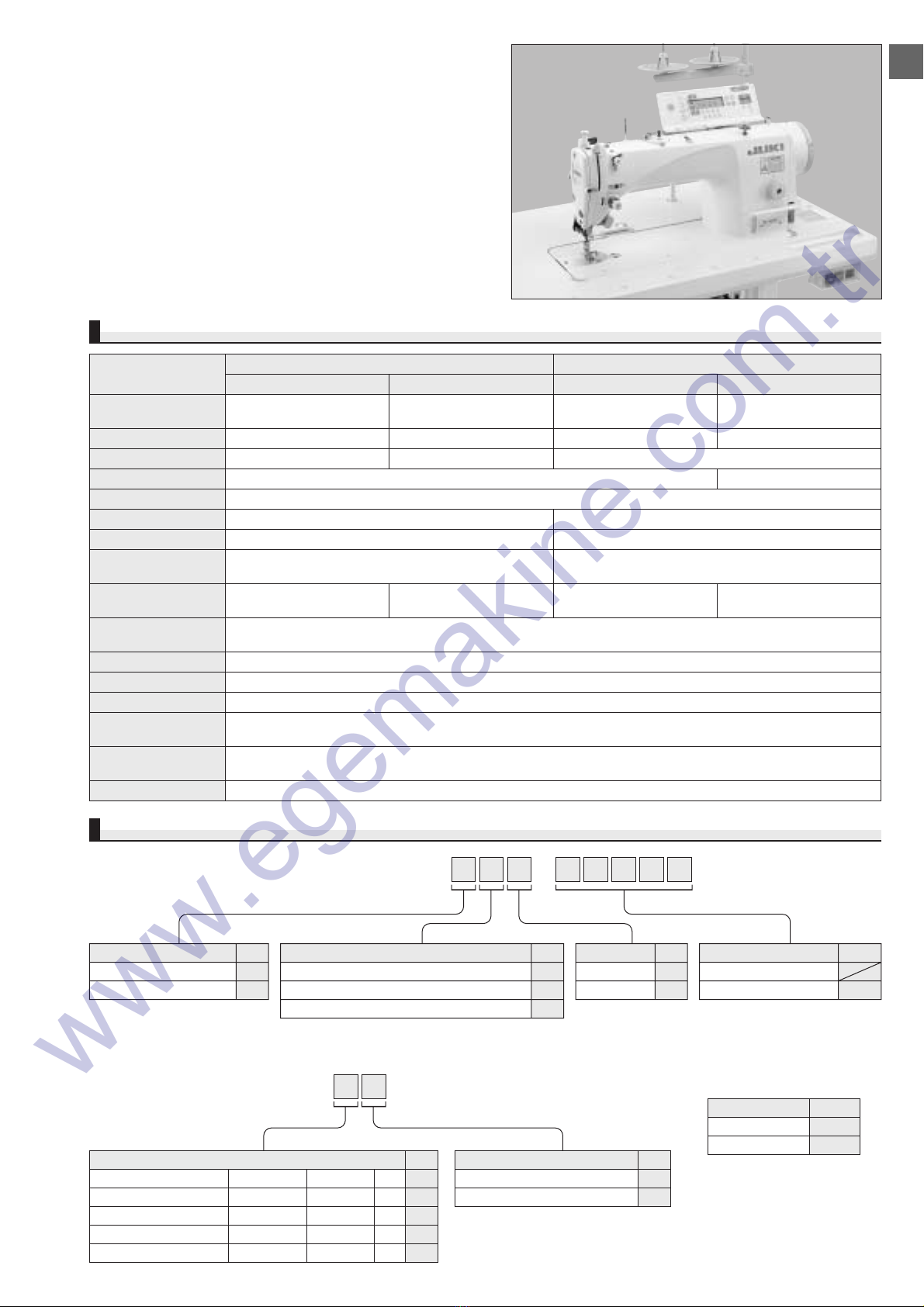

SPECIFICATIONS

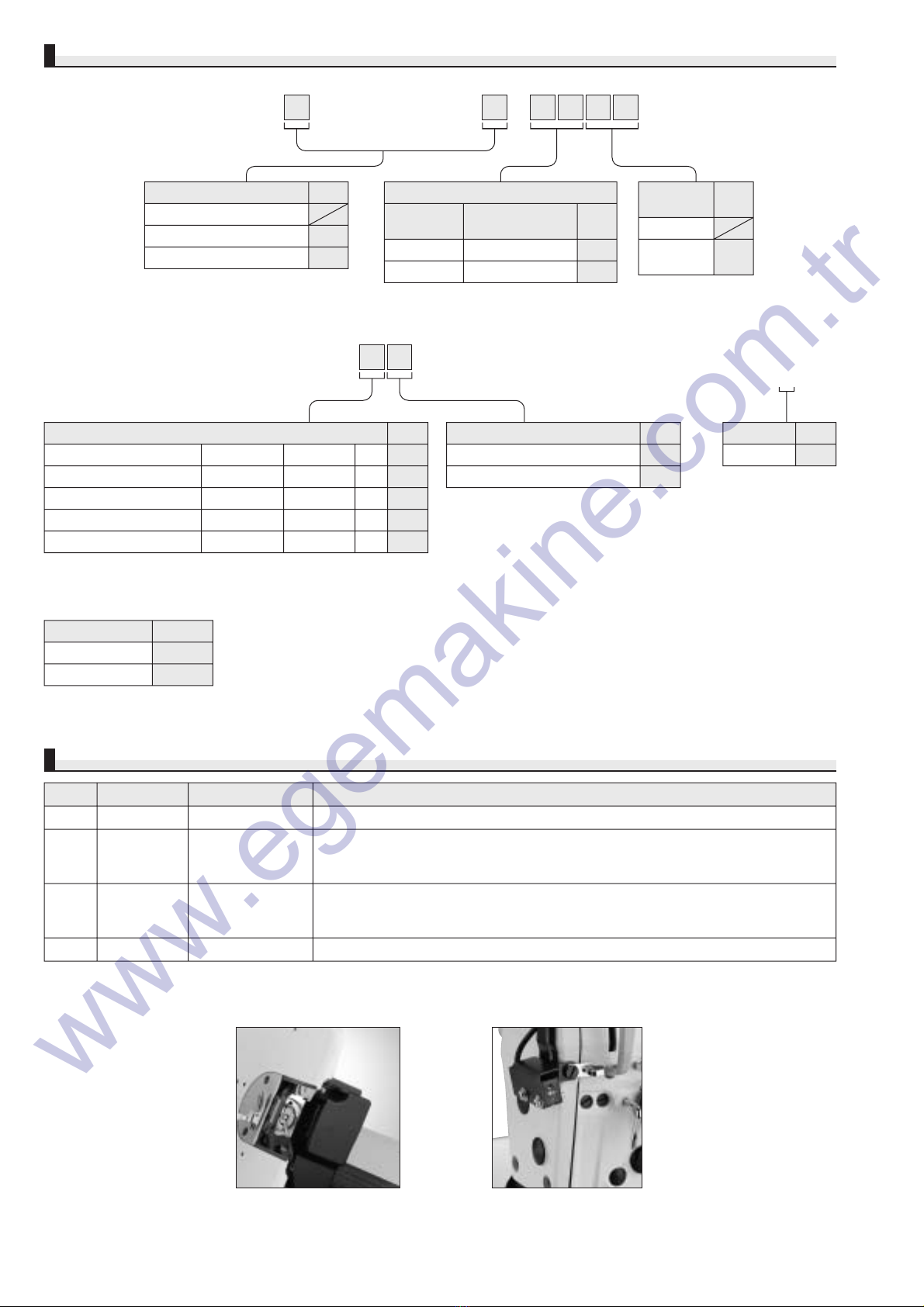

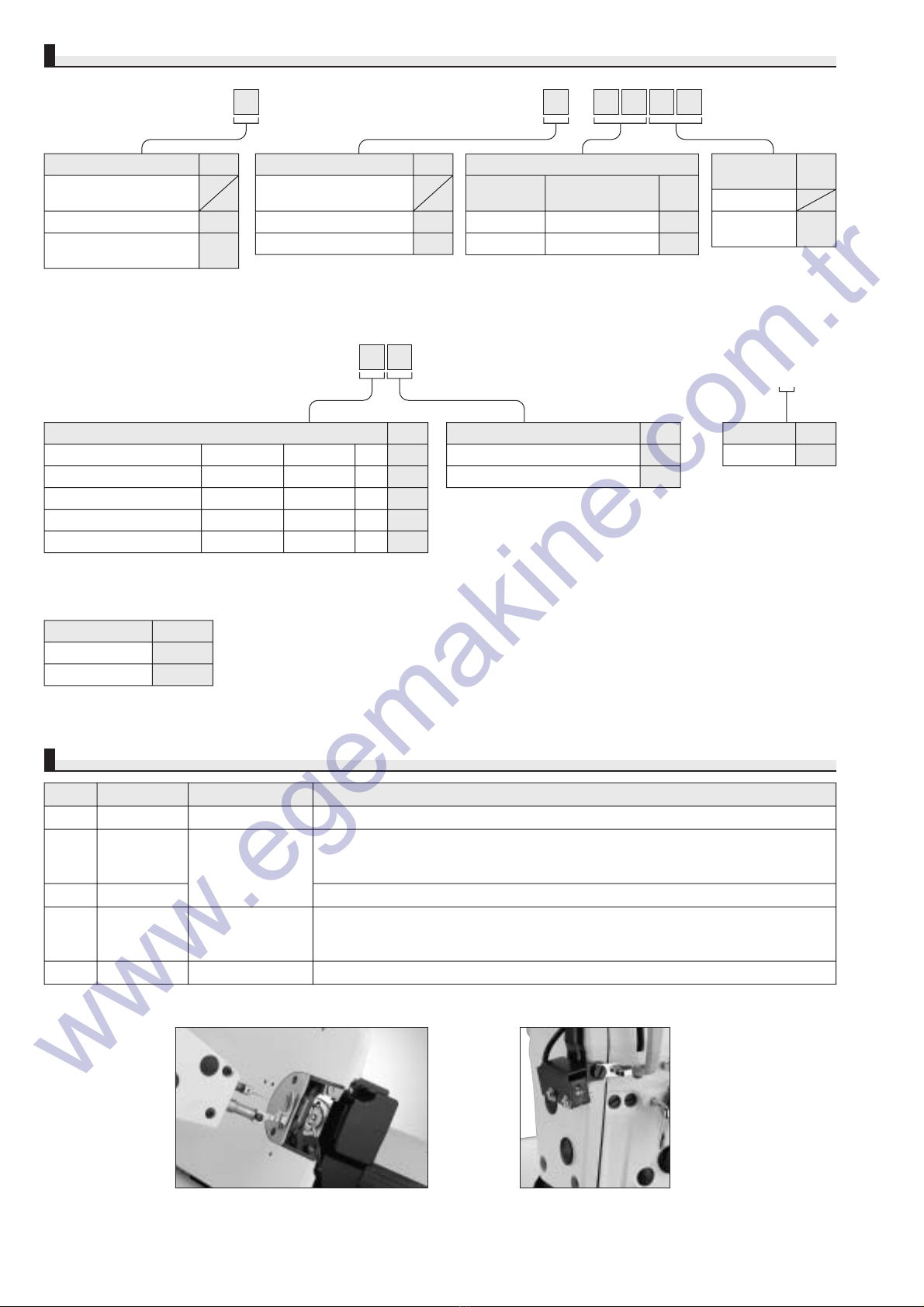

WHEN YOU PLACE ORDERS

●PSC box ●Operation panel

SC910

DDL9000 B

Machine head type Code

Dry head D

Minute-quantity lubrication

S

Operation panel Code

IP-100B IP100B

CP-160D CP160D

PSC box Code

For JUS(LA)*Single-phase 100〜120V PFL S

For JUS*, General Export 3-phase 200〜240V PFL D

For General Export Single-phase 200〜240V PFL K

For EU (CE) Single-phase 200〜240V PFL N

For China Single-phase 200〜240V PFL U

Application Code

For light- to medium-weight materials S

For heavy-weight materials H*

For extra light-weight materials and foundation

F*

Control box Code

Standard S

Provided with built-in I/O board A

*For the sewing specification "H," only the minute-quantity lubrication type (S type) machine head is available.

For the sewing specification "F," only the dry head type (D type) machine head is available.

Wiper Code

Not provided 0

Provided W

Device and attachment Code

Not provided

Auto-lifter (pedal-driven) AK118

● Control box provided with built in I/O board (Code A) should be selected for the machine

head equipped with the remaining bobbin thread detector (AE-8).

*JUS:North America and Central and South America.

Model name Dry head type Minute-quantity lubrication type

DDL-9000DS DDL-9000DF DDL-9000SS DDL-9000SH

Application For light- to

For extra light-weight materials

For light- to For heavy-weight materials

medium-weight materials

and foundation

medium-weight materials

Max.sewing speed 4,000rpm 3,500rpm 5,000rpm 4,500rpm

Max.stitch length 5mm 4mm 5mm

Needle bar stroke 30.7mm 35mm

Lift of the presser foot By hand :5.5mm, By knee :15mm, auto :10mm

Lubrication No lubrication Minute-quantity lubrication to needle bar and hook

Lubricating oil ―JUKI New Defrix Oil No.1 (equivalent to ISOVG7)

Hook Exclusive no-lubricating hook

(plastic hook with special-purpose race surface) Automatic lubricating hook

Needle DB×1 (#14) #9〜#18 DB×1 (#9) #8〜#11 DB×1 (#14) #9〜#18 DB×1 (#21) #19〜#23

(at the time of delivery)

For JE:134 (Nm75) Nm65〜Nm110 For JE:134 (Nm65) Nm65〜Nm75 For JE:134 (Nm75) Nm65〜Nm110

For JE:134 (Nm130) Nm120〜Nm160

Distance from

needle to machine arm 300mm

Size of bed 517mm×178mm

Bobbin thread winder Built-in the machine head

Machine head drive Compact AC servomotor that is directly connected to the main shaft (direct-drive system)

Automatic

reverse feed function Provided as standard

Power requirement

Power consumption Single-phase 100〜120V, 200〜240V, 3-phase 200〜240V/650VA

Total weight 84.5Kg