* For the control box and the operation panel, read the Instruction Manual for the SC-900.

CONTENTS

1. OUTLINE .................................................................................................................................1

1-1 Features.........................................................................................................................................................1

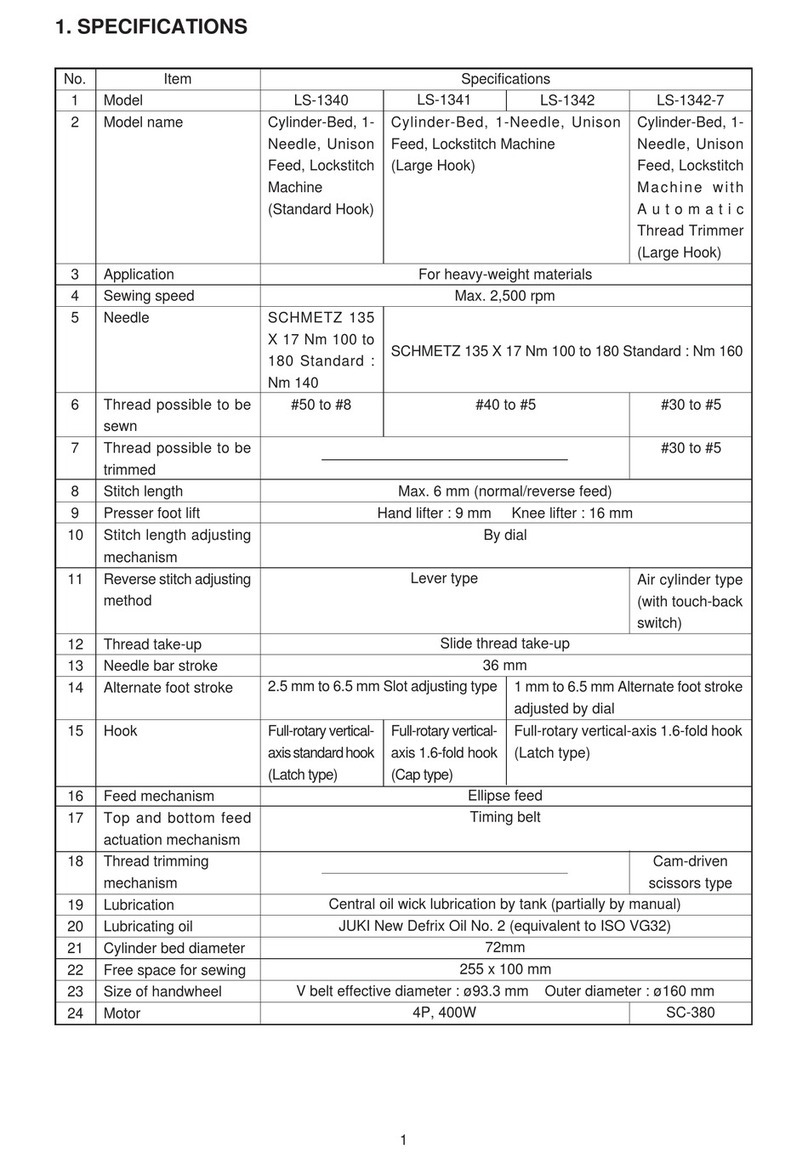

1-2 Specifications (Table of DDL-9000 series specifications) ........................................................................2

1-3 Application ....................................................................................................................................................4

1-4 Cautions when operating.............................................................................................................................4

2. OPERATION............................................................................................................................5

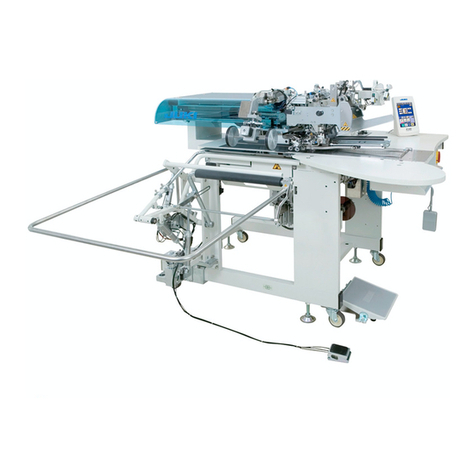

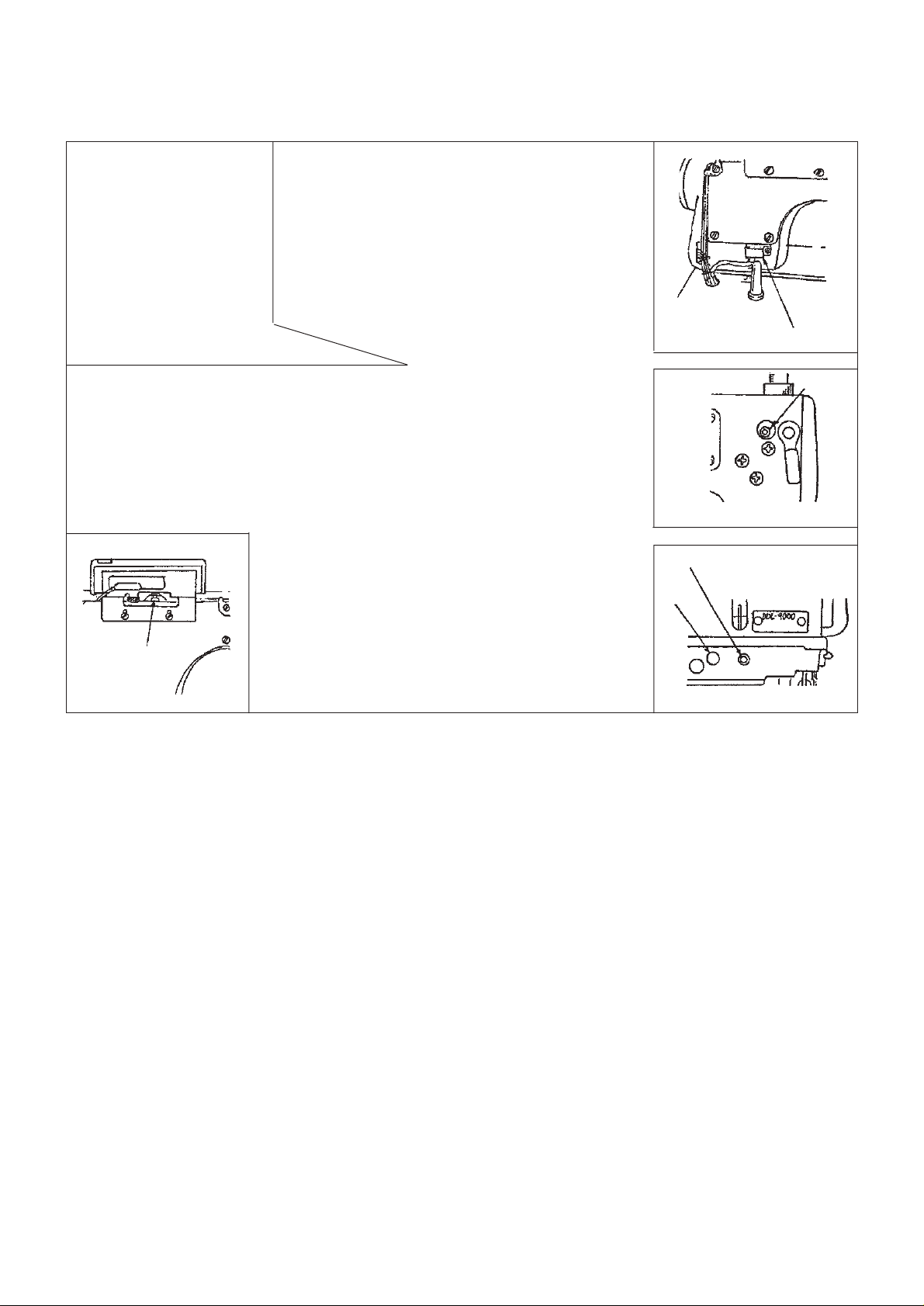

2-1 Configuration ................................................................................................................................................5

2-2 Check points before trial operation and operation ...................................................................................5

3. CONFIGURATION...................................................................................................................9

3-1 Adjusting the needle stop position.............................................................................................................9

3-2 Adjusting the wiper (WB type).....................................................................................................................9

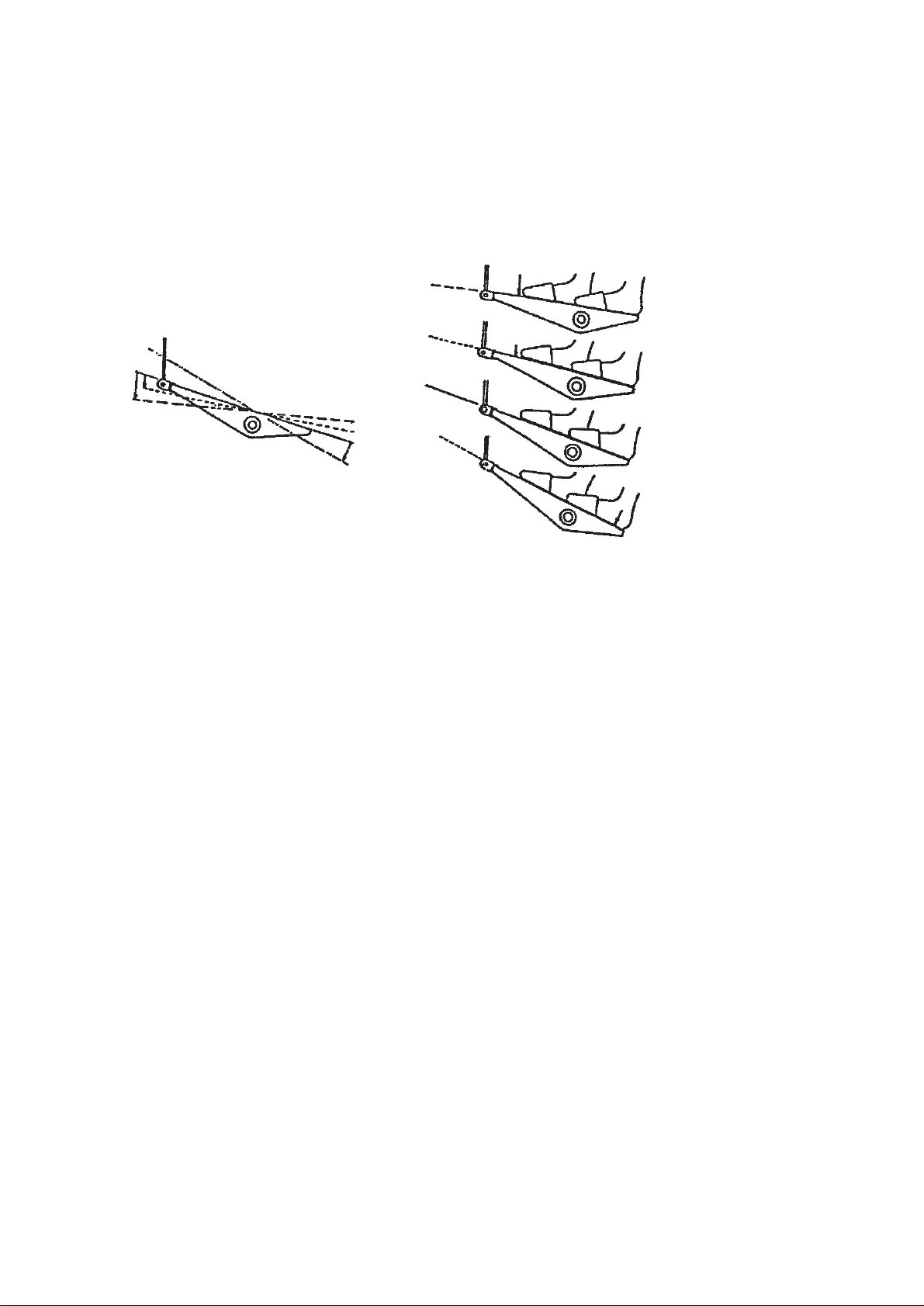

3-3 Principle of thread trimming......................................................................................................................10

3-4 Sequence of thread trimming ....................................................................................................................10

3-5 Observing and adjusting the thread trimmer cam timing.......................................................................12

3-6 Adjusting the position of moving knife movement .................................................................................13

3-7 Properly installing the counter knife ........................................................................................................15

3-8 Rising amount of the thread tension disk No. 2 ......................................................................................16

3-9 Sharpening the knife blade........................................................................................................................16

3-10 Replacing the moving knife .....................................................................................................................17

3-11 Replacing the thread guide for knife ......................................................................................................18

3-12 Adjusting the thread take-up picker .......................................................................................................18

3-13 Adjusting the clutch plate and the thread trimmer solenoid................................................................19

3-14 Driving arm stopper..................................................................................................................................19

3-15 Installing/removing the knife installing base .........................................................................................20

3-16 Adjusting the position of the touch-back switch...................................................................................21

3-17 Adjusting the position of the handwheel ...............................................................................................21

3-18 Adjusting the automatic presser lifter (AK118) .....................................................................................21

3-19 Optionals (Presser foot micro-lifter) .......................................................................................................25

3-20 AE-8 (Bobbin thread remaining amount detector) ................................................................................25

3-21 ED-4 (Compact material end sensor)......................................................................................................25

3-22 PK-70 and -71 (3-step pedal)....................................................................................................................25

3-23 Adjusting the tension release change-over ...........................................................................................26

3-24 Adjusting the presser foot micro-lifter ...................................................................................................26

3-25 Installing the operation panel..................................................................................................................26

3-26 Dimensions of table..................................................................................................................................27

3-27 Points of adjustment and assembly of the feed mechanism ...............................................................28

3-29 Points of adjusting and assembling the thread take-up and the needle bar mechanism .................34

3-29 Replacing the motor .................................................................................................................................35

3-30 Replacing the timing belt .........................................................................................................................35

3-31 Points of adjusting and assembling of the bobbin winder...................................................................36

3-32 Points of adjusting and assembling of the lubrication mechanism (SS, SH) .....................................37

3-33 Applying the exclusive grease ................................................................................................................38

3-34 Removing/attaching the gear box cover ................................................................................................39

3-35 Points of adjuting the sewing..................................................................................................................40

3-36 Adjusting the amount of oil in the hook ................................................................................................. 42

4. TROUBLES AND CORRECTIVE MEASURES (MECHANICAL PARTS)............................44

5. TROUBLES IN SEWING AND CORRECTIVE MEASURES ................................................50

6. BOBBIN CASE WITH IDLE-PREVENTION SPRING ...........................................................60