CONTENTS

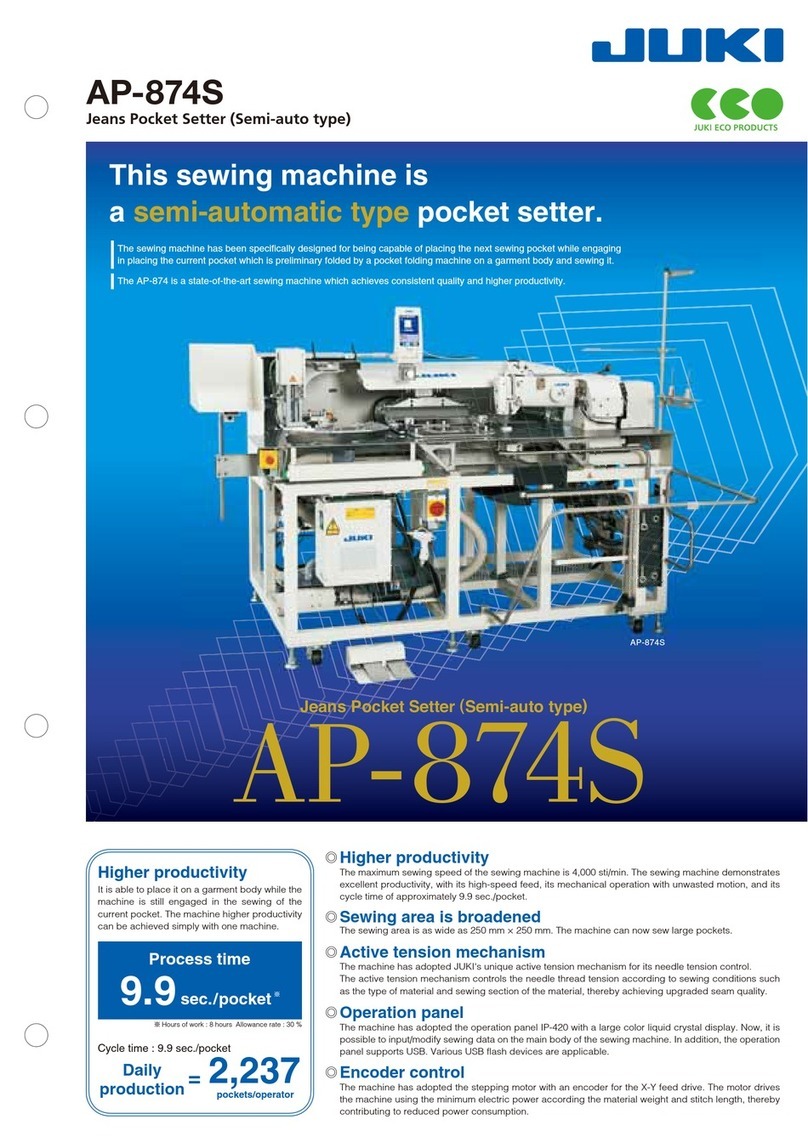

1. SPECIFICATIONS...................................................................................1

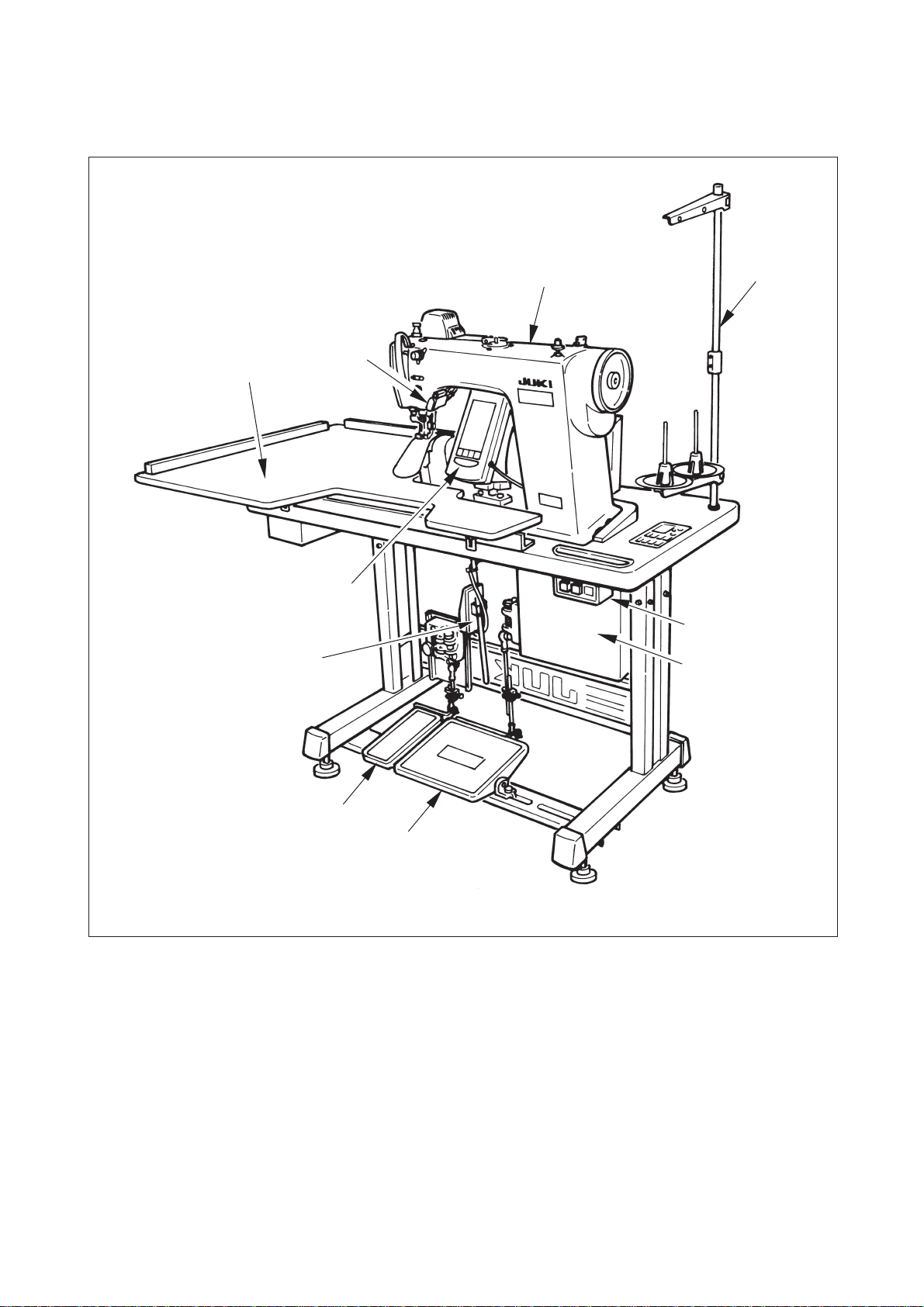

2. CONFIGURATION ..................................................................................2

(1) Sewing machine main unit ................................................................................. 2

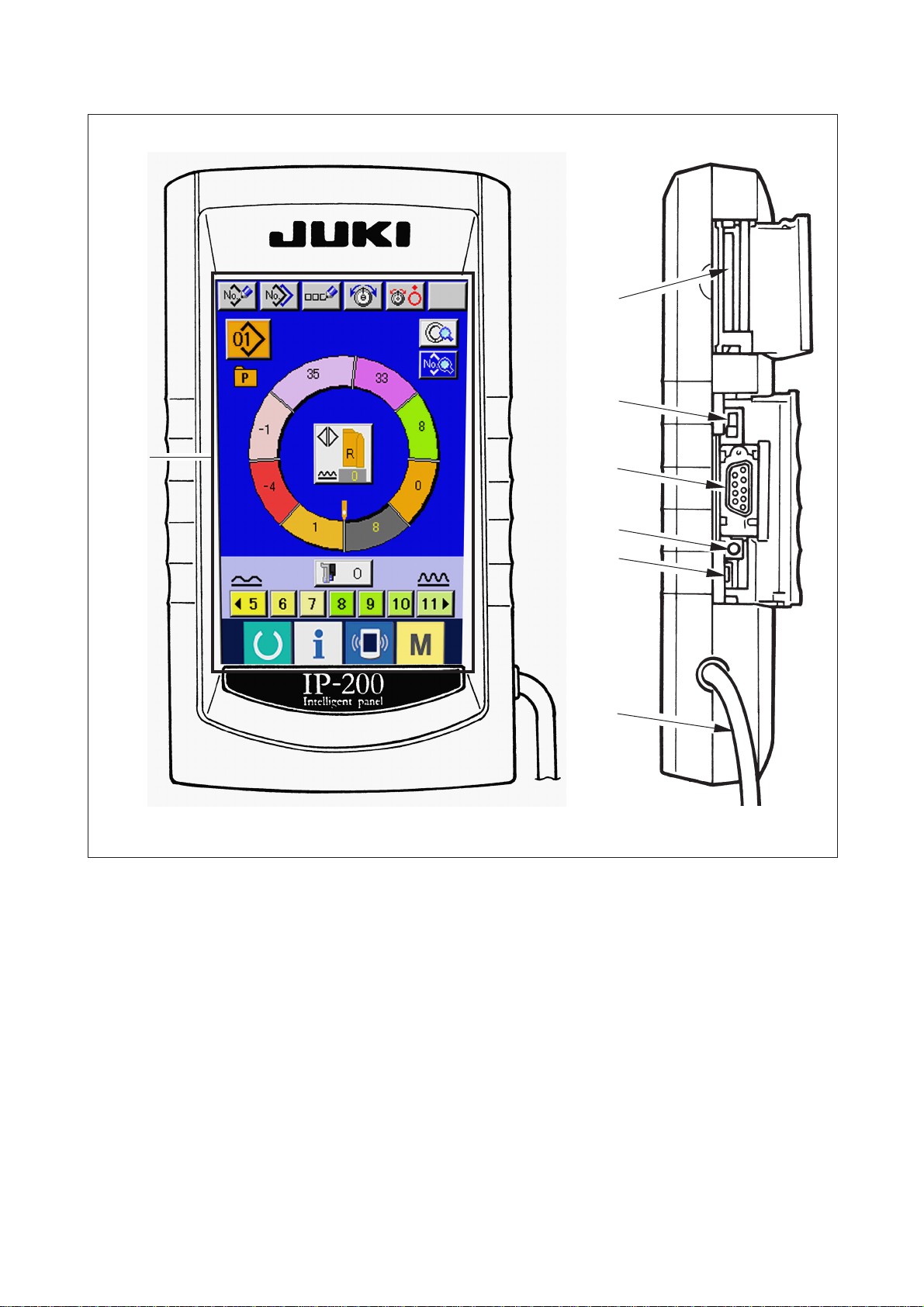

(2) Operation panel ................................................................................................... 3

3. STANDARD ADJUSTMENT ...................................................................4

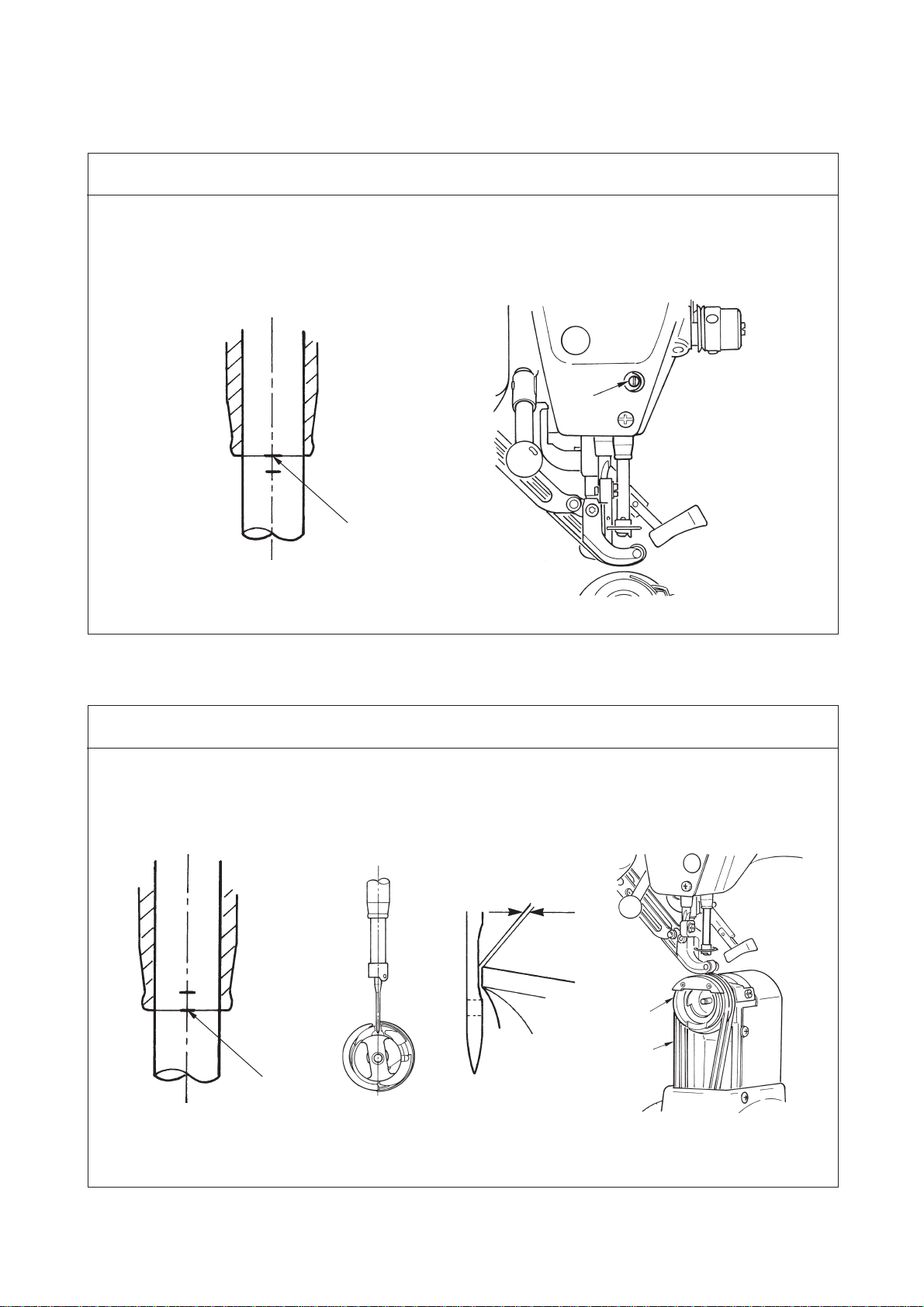

(1) Adjusting the height of the needle bar .............................................................. 4

(2) Adjusting the needle and the hook .................................................................... 4

(3) Removing the main shaft motor and the coupling ........................................... 6

(4) Adjusting the main shaft belt tension ............................................................... 8

(5) Adjusting the hook shaft belt tension ............................................................... 8

(6) Adjusting the feed belt tension .......................................................................... 10

(7) Adjusting the height of the feed foot bar .......................................................... 12

(8) Adjusting the height of the presser foot bar..................................................... 12

(9) Adjusting the amount of alternate vertical movement .................................... 14

(10) Height of the presser screw ............................................................................. 16

(11) Assembling the guide plate .............................................................................. 16

(12) Adjusting the initial position of the auto-lifter................................................ 18

(13) Adjusting the speed of the auto-lifter .............................................................. 18

(14) Adjusting the stroke of the auto-lifter ............................................................. 20

(15) Adjusting the thread trimmer cam ................................................................... 20

(16) Adjusting the initial position of the moving knife .......................................... 22

(17) Adjusting the initial position of the thread trimmer solenoid ....................... 22

(18) Adjusting the position of the moving knife and the counter knife ............... 24

(19) The fixing position of the auxiliary feed motor pulley ................................... 24

(20) The fixing position of the main feed motor pulley .......................................... 26

(21) The fixing position of the thrust collar of AT solenoid ................................... 26

(22) The fixing position of the thread tension shaft collar .................................... 28

(23) Adjusting the height of the feed foot ............................................................... 28

(24) Adjusting the height of the auxiliary feed foot ............................................... 30

(25) Adjusting the height of the presser foot ......................................................... 30

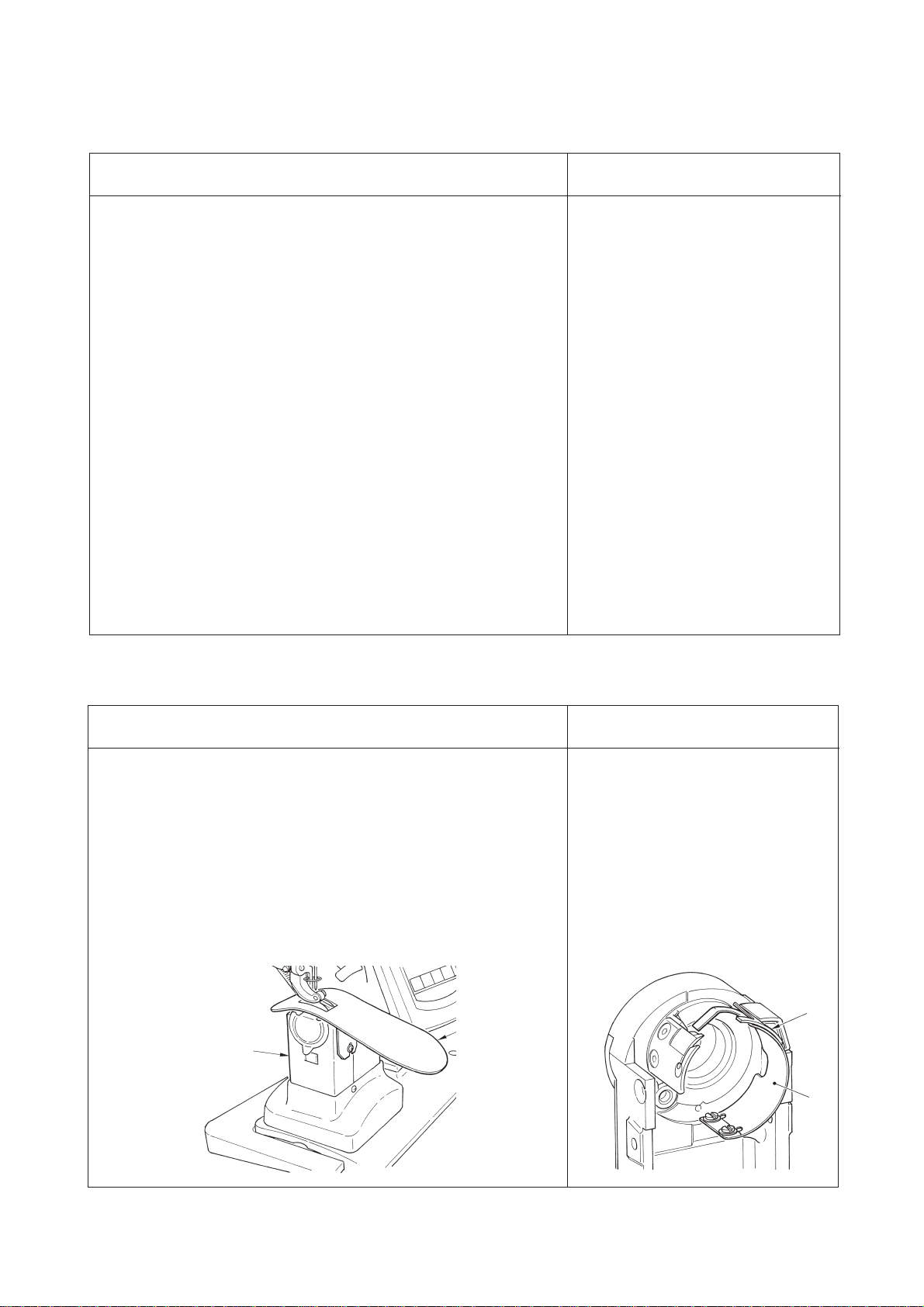

(26) Adjusting the feed eccentric cam .................................................................... 32

(27) Adjusting the assembly of the counter knife guard plate ............................. 32

(28) Replacing procedure of the top feed belt........................................................ 34

(29) Replacing procedure of the bottom feed belt ................................................. 48

4. PARTS TO BE GREASED ......................................................................50

5. SET-UP MANUAL FOR IP-200 ...............................................................52

(1) Connecting procedure of operation panel with external vehicle .................... 52

(2) Re-setup of operation panel ............................................................................... 56

(3) Re-setup of main program.................................................................................. 59

(4) Re-setup of servo program................................................................................. 65

(5) When using smart media other than that which has been packed

together ................................................................................................................ 71