Intended use

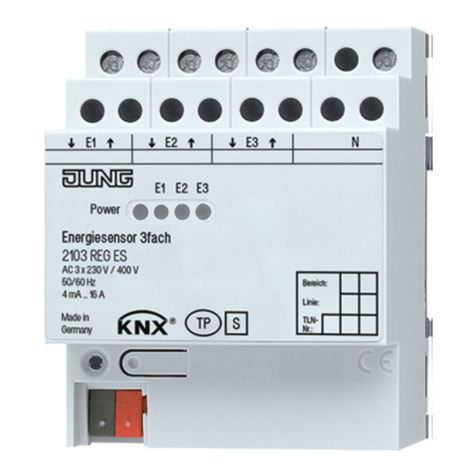

- Energy sensor to determine voltage, current and energy values

- Transfer of the measured values to the eNet server

- Operation with power supply RMD and receiver module RMD cover or eNet server (see

accessories)

- Installation in distribution boxes on DIN rail according to EN 60715

iThe energy sensor is not officially calibrated and may not therefore be used for invoicing

purposes.

Product characteristics

- Detection of the current and voltage of four separate circuits

- Separate calculation of the effective, idle, apparent power and the effective energy for each

measuring channel

- Event or time-controlled transmission of measured value telegrams to the eNet server

- Update of the device software

iThe parameter list is in the Internet in the documentation for this device.

Functional description

The energy sensor records and calculates various characteristic electrical values of the

connected consumers. It is possible to display these values using the visualisation of the eNet

server. All the energy sensors available in the building installation can be monitored using the

eNet server (see technical documentation of the eNet server).

Time and event-controlled data transmission

The energy sensor determines the current consumption data every 0.2 seconds. The data can

be transmitted at a configurable transmission of 1...60 minutes.

In addition, data transmission can be coupled to the change in effective output. If the effective

output exceeds a value of 1...2000 W and the deviation to the most recently transmitted value is

1...50 %, the data is transferred again, but only after at least one minute.

Default setting

Time-controlled transmission, transmission interval: 15 minutes

Event-controlled transmission:

Rel. threshold value, effective output: 10 %

Abs. threshold value, effective output: 1 W

Transferred characteristic electric values

- Current

- Voltage

- Average effective output

Interval for average formation configurable between 0.2...300 s.

- Apparent output

- Fundamental oscillation idle power

- Effective energy

The total effective energy is saved to power failure-proof memory.

4 Information for electrically skilled persons

4.1 Fitting and electrical connection

DANGER!

Electrical shock when live parts are touched.

Electrical shocks can be fatal.

Before working on the device, disconnect the power supply and cover up live

parts in the working environment.

Fitting the device

oMount device on DIN rail. Output terminals must be at the top.

2/8

82582003

J:0082582003 14.03.2014

eNet

Radio energy detector, 4-channel, for rail mounting