REV. 0

09-11-

HELIX SYSTEM INSTALLATION, USE AND MAINTENANCE MANUAL

8 / 32

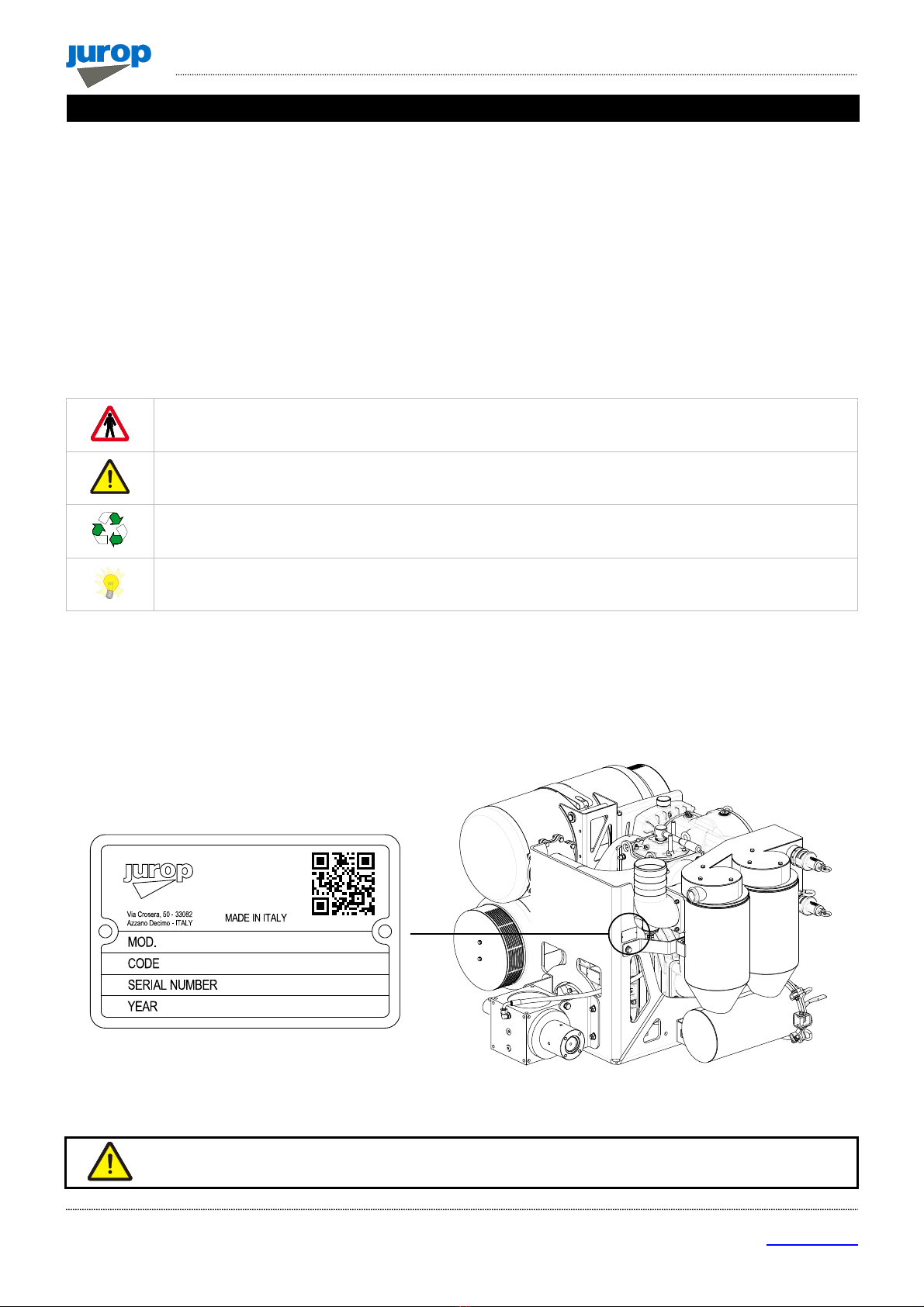

Jurop SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

TEL. +39 0434 636811 FAX. +39 0434 636812

http://www.jurop.it

2.5. Hydraulic motor power supply

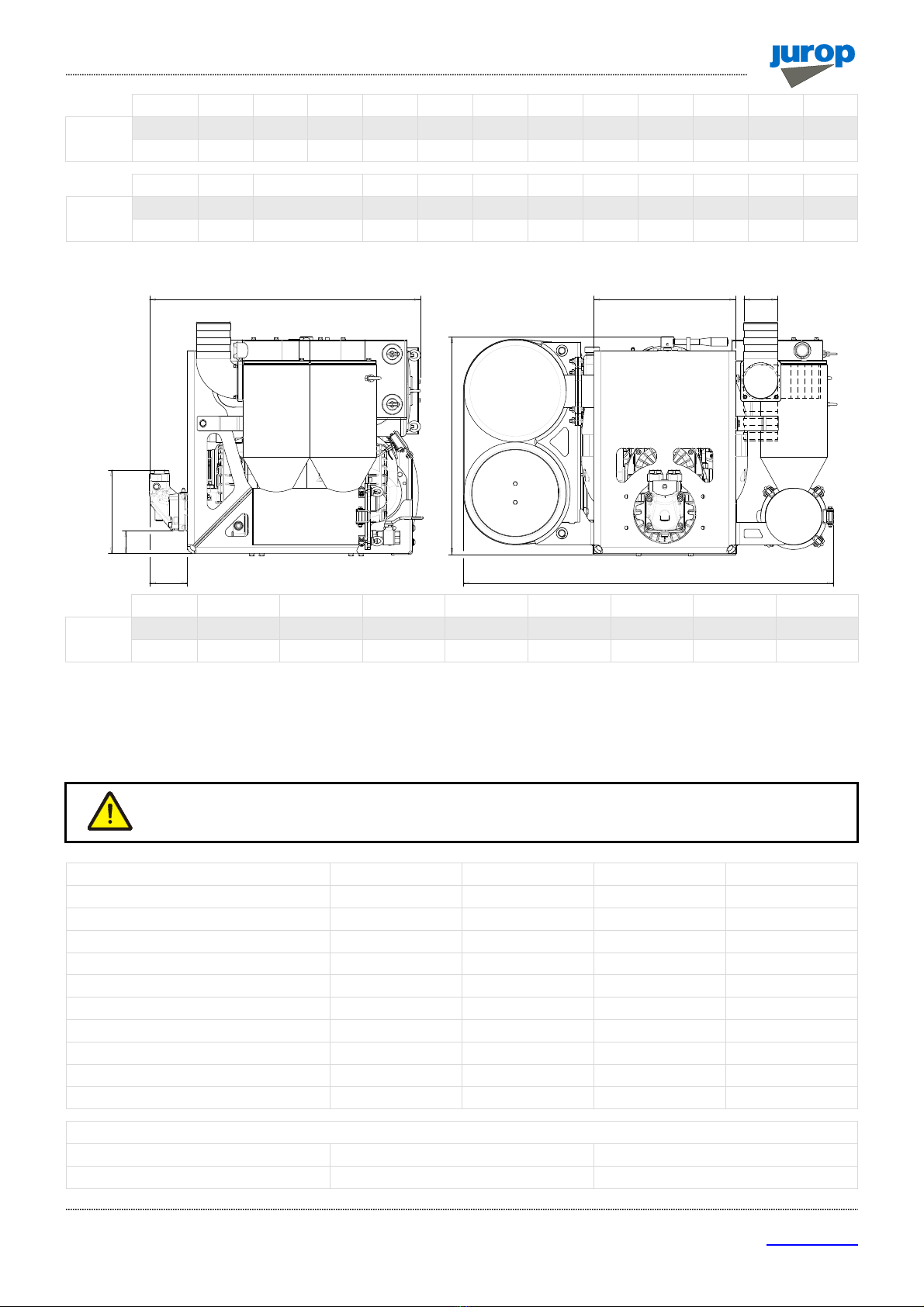

The performance data of the hydraulic motor are given in the following table.

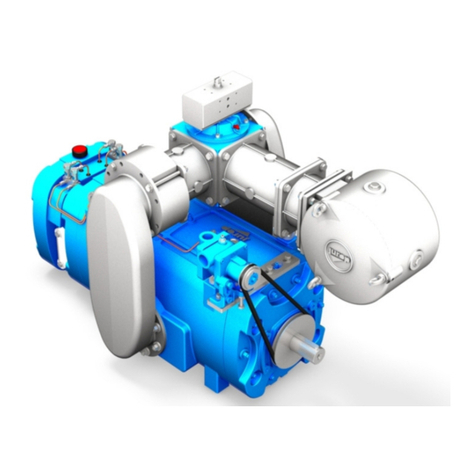

HELIX 300 SYSTEM with hydraulic motor

Displacement 40 cc/rev Filtration class 20/18/13 (ISO 4406)

Continuous pressure 1420 bar Optimal viscosity 15-30 cSt

Max. drain line pressure 1 bar Max. viscosity 1000 cSt

Fluid HLP Max oil temperature 280 °C

1Motor in continuous service. With pump operating within the prescribed operating limits, the actual working pressure is always lower. | 2With

reference to the temperature of the oil present in the main circuit.

2.6. Noise

The sound pressure and sound power values of the pump are given inside the HELIX vacuum pump/compressor manual.

The noise value in Db varies according to the system realised, and the supply and suction pipes. Please remember to use Personal Protective

Equipment (headphones) to reduce the effect of noise.

Sound power verification cannot be performed without completion of the vacuum line system. This verification is the responsibility of the final

installer.

Apply these prescriptions carefully.

3.1. General recommendations

When transporting the unit, fasten appropriately. Rest the unit on stable points.

Installation and maintenance must be done with the unit stopped, power transmission disengaged and by skilled personnel.

Work on the unit dressed appropriately (avoid ties, wide sleeves, necklaces, etc.) and using suitable protective equipment (gloves, goggles,

shoes, etc.).

Before any maintenance operations, stop the unit and bring the system back to atmospheric pressure.

To intervene on the unit, all the components of the unit must be stopped and cold.

To prevent errors and hazardous situations, establish what each operator is responsible for in the different maintenance operations.

Final manufacturer must make the transmission inaccessible by means of a fixed guard or interlocked movable guard. Do not start the unit up

without the safety devices required for the transmission parts. Replace damaged protections.

Operators working in the vicinity must avoid prolonged exposure to the noise emitted by the suction equipment if they are not equipped with

suitable protection (PPE recommended: ear protectors).

The components can reach very high temperatures (over 90°C) during operation. Use all means necessary to avoid contact.

During vacuum operation, avoid accidental intake of solids: they can be projected at high speed through the discharge manifold, damaging the

silencer.

Safety valves: direct the air flow away from operators.

Do not use the unit beyond its limits of use: risk of breakage with consequences for the operators.

Do not exceed the rotation speed and maximum pressure given in the technical table in paragraph 2.4.

Based on the final use of the unit, the insertion in the housing machine and the typology of the same, the designer of the housing machine must

apply safety signals (pictograms) to warn the operator on the risk still present. These pictograms essentially refer to three categories:

3. Safety and accident prevention