REV

02-12-2019

INSTALLATION

,

USE AND MAINTENANCE MANUAL

–

PNR/E 73-83-104-124

–

PNR 142

9 / 44

Vi Croser n° 50

33082 Azz no Decimo, PN (It li )

EL

AX

http://www.jurop.it

Recommended oils nd gre ses: GEARBOX

Viscosity Type ENI ESSO SHELL TOTAL MOBIL BP

HAVOLINE

ISO VG 220 Miner l Oil Bl si 220 Sp rt n EP 220 Om l oil 220 C rter EP 220 Mobilge r 630 Energol GR XP 220 Merop 220

Attention: caref lly apply these prescriptions.

3.1. General recommendations

• When tr nsporting the compressor use proper slinging. Store the

compressor in st ble pl ces.

• Inst ll tion nd m inten nce must be c rried out with the unit

tot lly diseng ged from its drive system nd must be performed by

qu lified personnel.

• Use dequ te clothing ( void ties, loose sleeves, neckl ces nd so

on) nd suit ble protection equipment (gloves, protection gl sses,

boots...).

• Before e ch m inten nce oper tion, stop the pump nd restore

the tmospheric pressure.

• M ke sure th t ll the p rts of the unit re idle nd cool, before

performing ny m inten nce oper tion.

• To prevent errors nd h z rdous situ tions, est blish wh t e ch

oper tor is responsible for in the different m inten nce oper tions.

• Do not st rt the m chine if the protection devices provided for

tr nsmissions re removed. Repl ce d m ged p rt.

• Fin l m nuf cturer must m ke the tr nsmission in ccessible by

me ns of fixed gu rd or interlocked mov ble gu rd.

• Oper tors working ne rby must void prolonged exposure to the

noise emitted by the spir tor, if not equipped with the proper e r-

protection devices (IPDs recommended: e r protectors).

• When the pump is running, some p rts m y re ch very high

temper tures ( bove 70°C). Use ll necess ry prec utions to void

cont ct.

• Avoid ccident l suction of solids: solids m y be projected t high

speed through the exh ust m nifold nd c use injures. A filter must be

mounted on the suction line (Mesh 55).

• Pressure relief v lve: point the ir flux w y from the oper tors.

• Do not use the spir tor over its designed limits: the m chine m y

be d m ge nd the oper tor m y be injured.

Do not exceed the speed and the power s pply

parameters indicated in the technical tables (see

par. 2.2 - 2.3).

• B sed on the fin l use of the decompressor, the insertion in the

housing m chine nd the typology of the s me, the designer of the

housing m chine must pply s fety sign ls (pictogr ms) to w rn the

oper tor on the risk still present. These pictogr ms essenti lly refer to

three c tegories:

- Sign ls prescribing the use of Individu l Protection Devices (IPDs)

such s, in this c se, the use of gloves nd e r protectors.

- Sign ls indic ting to p y p rticul r ttention to the d ngers rel ted

to the m chine’s components, such s: risk of dr gging in the

tr nsmission equipment nd cont ct with hot surf ces.

- Sign ls indic ting specific p rts of the m chine for n e sier

identific tion, such s: gre sing points, oil t nks, etc.

3.2. Intended se

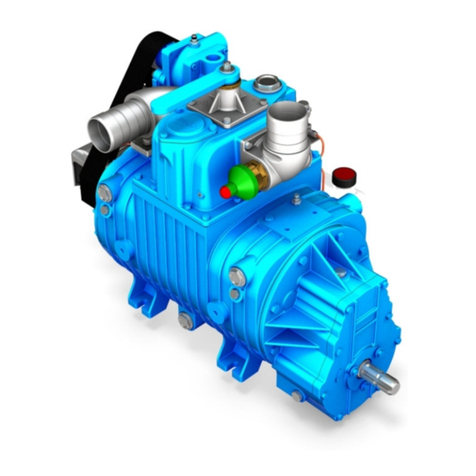

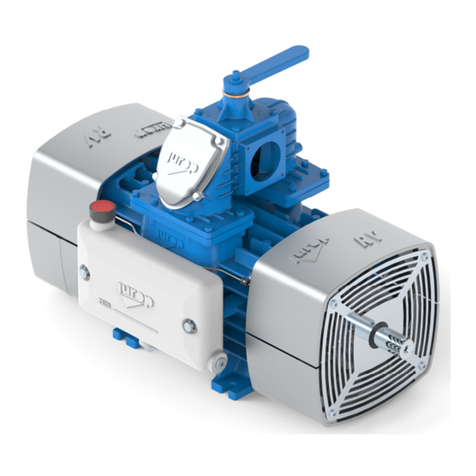

• V cuum pumps of the PNR/PNE series re commonly used on

st tion ry or mobile equipment for suction nd tr nsfer by me ns of

v cuum or soc lled pneum tic-tr nsport tion of liquid nd solid w stes.

Any other us ge sh ll beconsidered improper.

• They re ir-cooled nd consequentely foreseen for non-

continuous duty. The mod. PNE nd the mod. PNR, the l tter supplied

with ir injection system (fig. 1) nd me nt for he vy duty works, do not

ccept oper ting temper tures over 150 °C (300 °F), checked t not

more th n 150 mm from the disch rge connections.

• Do not s ck toxic subst nces nd infl mm ble or explosive

g sses, since the intern l components of the pump m y re ch high

temper tures.

Avoid s ction of toxic (poisono s) explosive or

flammable gasses beca se internal components

may reach high temperat res.

• Avoid suction of liquids or solids, they c n seriously d m ge the

pump.

Attention: liq ids or solids infiltrations can

serio sly damage the p mp.

• Do not run the pump over its designed oper ting limits (see p r.

2.3): it m y bre k nd tr nsmission c n be d m ged.

3.3. Conveyed fl ids

• PNR/PNE re suit ble for conveying filtered ir. Before conveying

other kind of g ses, verify comp tibility with pump’s ch r cteristics.

• The m chine w s not designed nd built to oper te in

environments with potenti lly explosive tmosphere (outdoor or

indoor).

• Ple se cont ct JUROP’s Technic l dept. if necess ry.

Safety and accident prevention