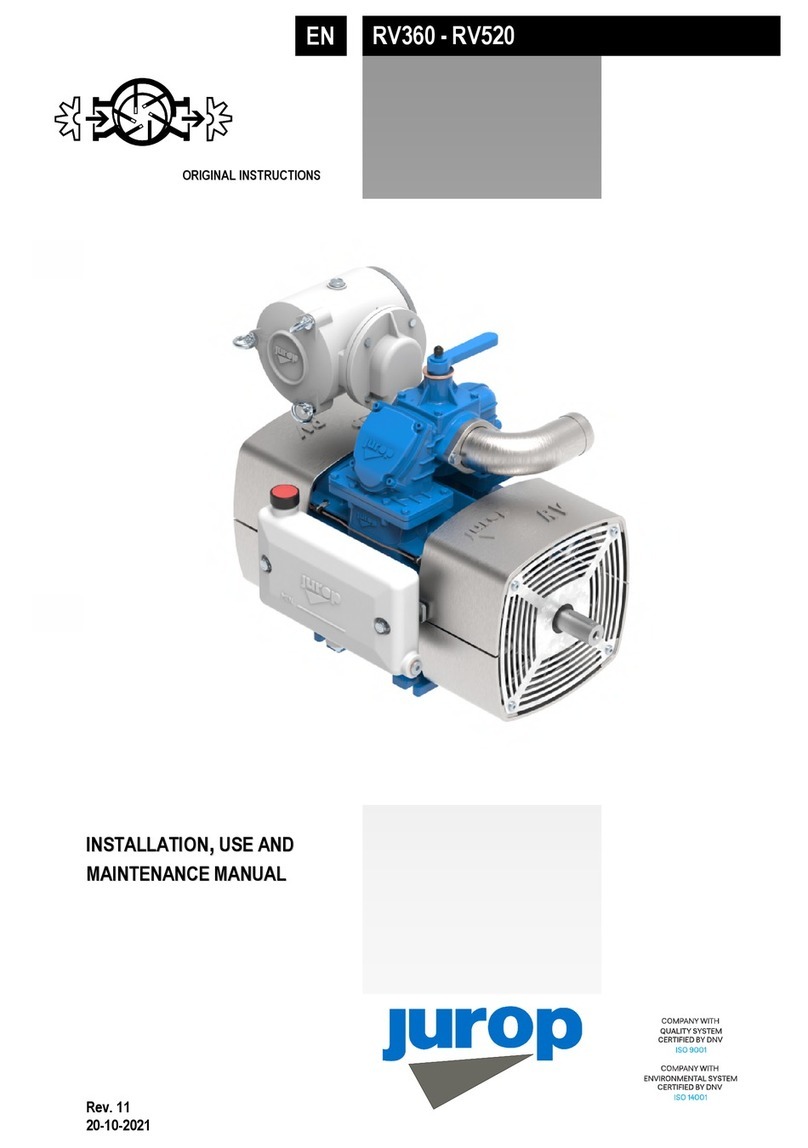

http://www.jur p.it

e-mail: inf @jur p.it

• Rem ve the p rt guards when m unting. The pipes and

c mp nents f the wh le line must be clean.

• Av id c nstricti ns and tight curves where they are n t essential.

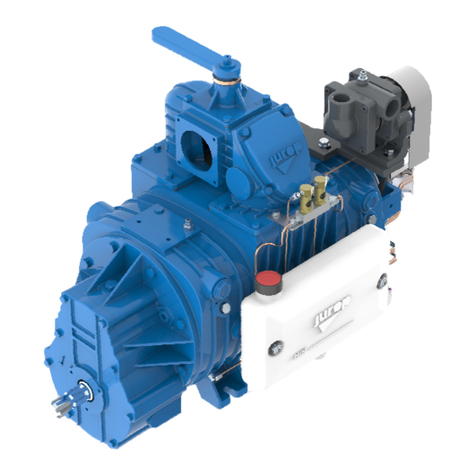

• C nnect the pump t the tank thr ugh the sucti n manif ld (Fig.

4.1 - p s. 8) which has a threaded p rt f r fitting the ver-pressure

valve.

• The exhaust pipes can reach high temperatures. Pr tect th se

adequately fr m the perat r reach.

• A clapet valve n sucti n pipe av ids r tati n in the pp site

directi n when the pump st ps.

• T av id that f reign liquids will enter the vacuum pump it is

necessary t m unt n the sucti n line an ver-fl w valve f “fl ating-

ball” type (Fig. 4.2. - p s. 1). The fl w secti n f this valve must be

equivalent t the sucti n h se’s ne.

• It is als necessary t have n the line a suitable air filter f r

preventing s lids t be sucked inside the vacuum pump. It is als

rec mmended t m unt a “sec ndary shut ff” f fl ating-ball type (Fig.

4.2 - p s. 2) between vacuum pump and ver-fl w (primary shut ff),

al ng with the previ usly menti ned air filter (Fig. 4.2 - p s. 3).

• Called als 4-way valve, n rmally is manually perated but it can

be at any time transf rmed in pneumatically r hydraulic perated up n

request f the appr priate kit.

• During n rmal running f the pump the resulting n ise sh uld be

reduced by means f a suitable silencer (Fig. 4.2 - p s. 4) m unted as

cl se as p ssible t the pump itself. It has t be dimensi ned f r the air

fl w pr duced by the pump m del. The il used f r the pump’s inside

lubricati n has t be separated fr m the exhausted air by means f an

adequate il-separat r, placed directly inside the silencer. The silencer

is fitted als with a draining tap f r the c llected il and c ndensed

liquids

• Over-pressure safety relief valve. It must be dimensi ned t

discharge the entire air-fl w f the pump. The adjustement f this valve

has t be kept inside 10% f t llerance f the pump's w rking pressure

and in any case it has t stay inside the given value f the tank's w rk

pressure.

• F r pumps that reach, during n rmal perating, discharge air

temperature cl se t 150 °C (300°F) - (checked at n t m re than 150

mm fr m the discharge c nnecti n) it is necessary t use a device

( verheating limiter) that will n t all w t exceed such temperature.

C ntact ur Technical Department.

• An adjustable curved pipe is installed n the utlet f the silencer,

in rder t prevent rain fr m entering and t enable p siti ning (during

installati n) f the utput airfl w.

• Direct the silencer discharge utput away fr m the silencer sucti n

inlet in rder t prevent the input f h t fluids int the injecti n inlet.

Atte tio : direct the sile cer discharge output

away from the sile cer suctio i let.

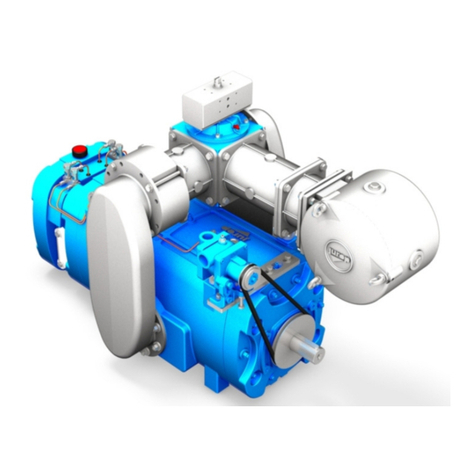

4.5 Hydraulic actuator adjustme t

• Extra rdinary maintenance perati ns can require the upper c ver

(and that f the actuat r, either manual r pneumatic) t be rem ved.

We rec mmend ensuring en ugh space t carry ut such perati ns.

• If the c ck bl cks r it m ves with fricti n, screw up the clearance

regulati n nut (A). Screw up ¼ f turn each time. Bl ck the nut r tati n

with the safety nut.

• The lubricati n p ints (B) and the clearance regulati n b lt (A)

must be accessible. See Fig. 4.5.

• Lubricate with grease every 1000 cycles. Grease type NLGI 2.

• It is suggested t install 2 ne‐way fl w c ntr ller between the

hydraulic switch and the hydraulic actuat r. Set the fl w c ntr llers in

rder t prevent hard hitting thr ugh the end f str ke. Minimum

c mmutati n time: 1 sec nd.

• Maximum feed pressure: 30 bar.

• T rder spare parts see spare parts list at the end f this manual.

Pic. 4.3

4.6 P eumatic actuator adjustme t

• In the event f 4-way valves equipped with pneumatic actuat r, we

rec mmend installing tw ne-way fl w regulat rs between the

pneumatic “c ntr l” and the pneumatic actuat r. The f ll wing figure

sh ws a schematic view f a p ssible pneumatic installati n.

Pic. 4.4

• We rec mmend adjusting the tw fl w regulat rs in rder f r

r tati n t ccur with ut kn cks and with a switching time f at least

ne sec nd.

4.7. Pump mou ti g - drive co ectio

A) Carda shaft drive

• Use telesc pic cardan shafts.