http://www.jur p.it

e-mail: inf @jur p.it

Attenti n:

Carefully apply these prescripti ns.

3.1 General rec mmendati ns

• Installati n and maintenance must be carried ut with the unit

t tally disengaged fr m its drive system and must be perf rmed by

qualified pers nnel.

• Use adequate cl thing (av id ties, l se sleeves, necklaces and

s n) and suitable pr tecti n equipments (gl ves, pr tecti n glasses,

b ts...).

• T prevent err rs and hazard us situati ns, establish what each

perat r is resp nsible f r in the different maintenance perati ns.

• When transp rting the pump, use pr per slinging. St re the pump

in stable places.

• Make sure that all the parts f the unit are idle and c l, bef re

perf rming any maintenance perati n.

• Bef re each maintenance perati n, st p the pump and rest re

the atm spheric pressure.

• When the pump is running, s me parts may reach very high

temperatures (ab ve 100°C). Use all necessary precauti ns t av id

c ntact.

• Operat rs w rking nearby must av id pr l nged exp sure t the

n ise emitted by the aspirat r, if n t equipped with the pr per ear-

pr tecti n devices.

• Av id accidental sucti n f s lids: s lids may be pr jected at high

speed thr ugh the exhaust manif ld and cause injures. A filter must be

m unted n the suncti n line.

• D n t start the machine if the pr tecti n devices pr vided f r

transmissi ns are rem ved. Replace damaged parts.

• Pressure relief valve: p int the air flux away fr m the perat rs.

• D n t use the aspirat r ver its designed limits: the machine may

be damage and the perat r may be injured.

D n t exceed the p wer supply parameters

indicated in the technical tables (see par. 2.4).

3.2 Intended use

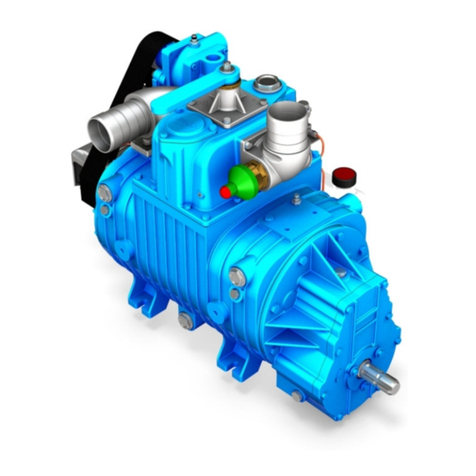

• The vacuum pumps RV are designed t c nvey filtered air int

systems f r the vacuum pr ducti n (example: systems f r the sucti n

f p wders r liquid wastes). Any ther usage shall be c nsidered

impr per.

• D n t sack t xic substances and inflammable r expl sive

gasses, since the internal c mp nents f the pump may reach high

temperatures.

• Liquids r s lids infiltrati ns can seri usly damage the pump.

• D n t run the pump ver its designed perating limits (see par.

2.4): it may break and transmissi n can be damaged.

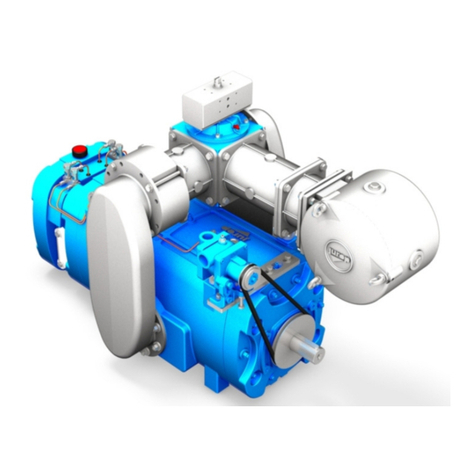

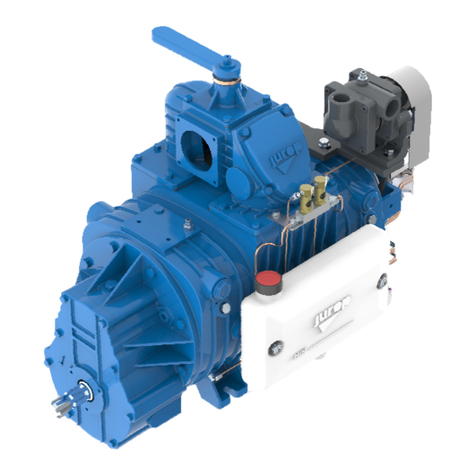

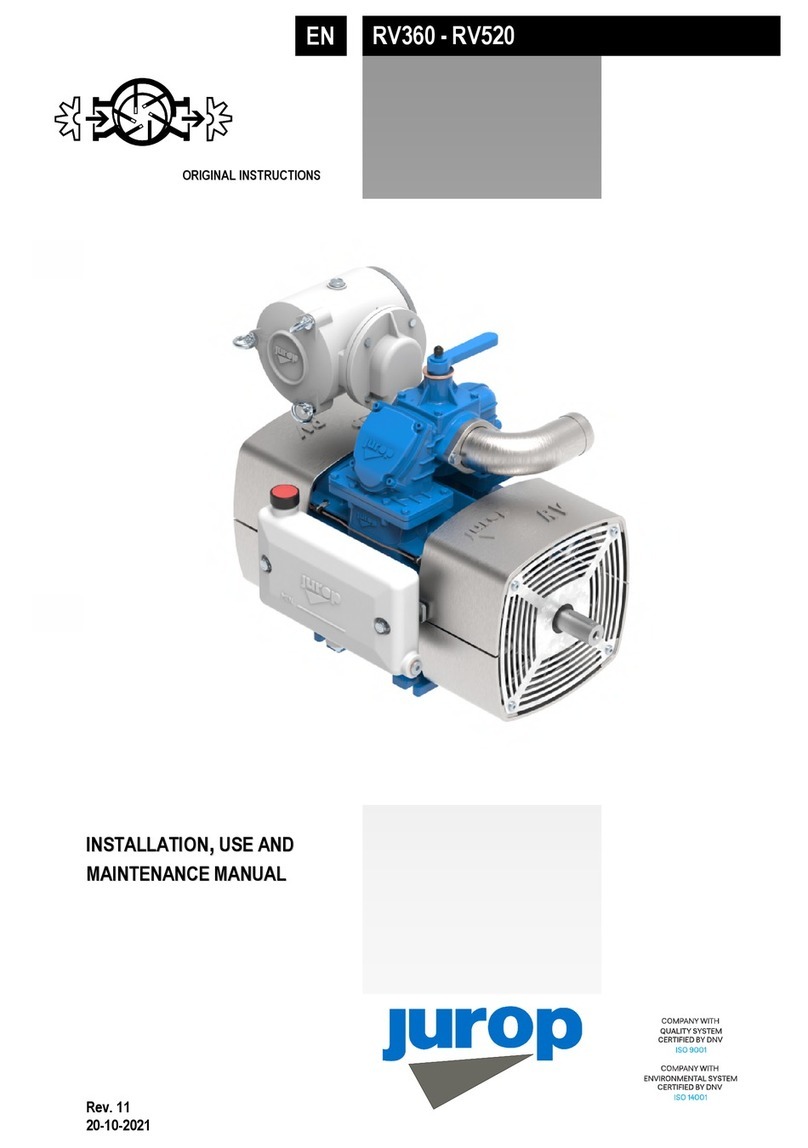

Legend f main c mp nents

1. Manif ld 5. Oil Tank 9. Lubricati n pump

2. Vacuum-pressure manif ld 6. Tank il stand 10.