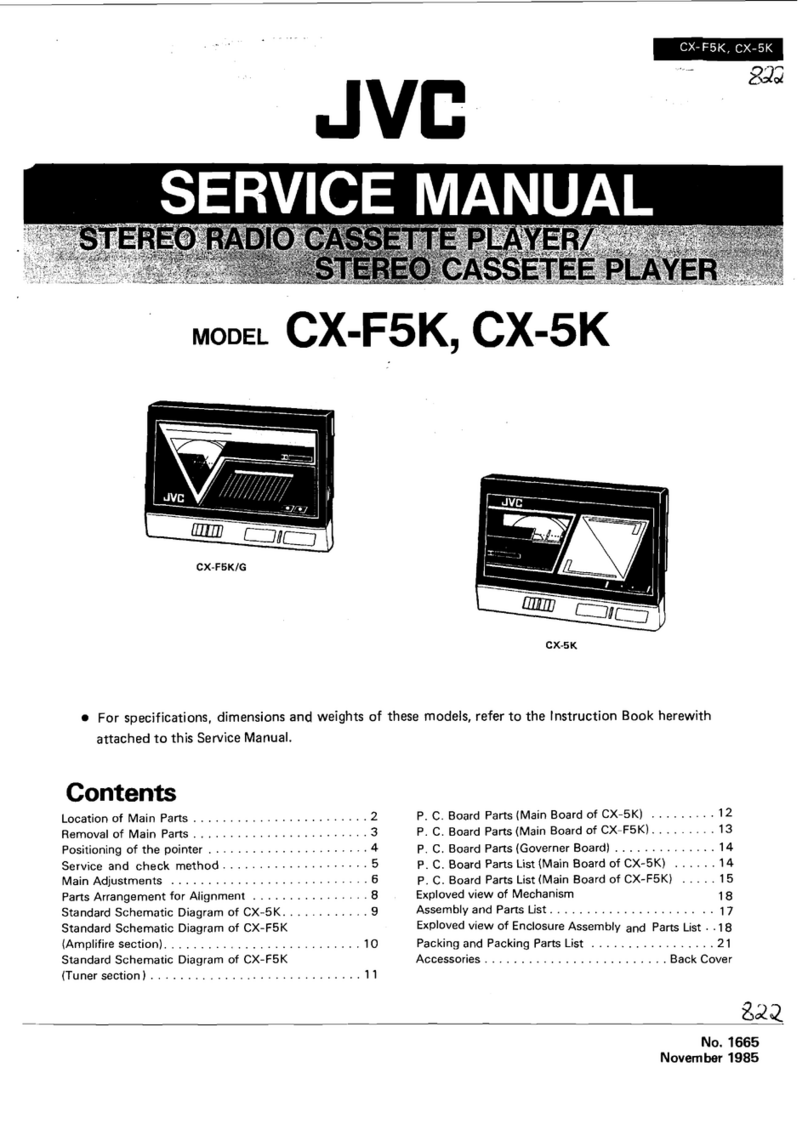

Contents

Page

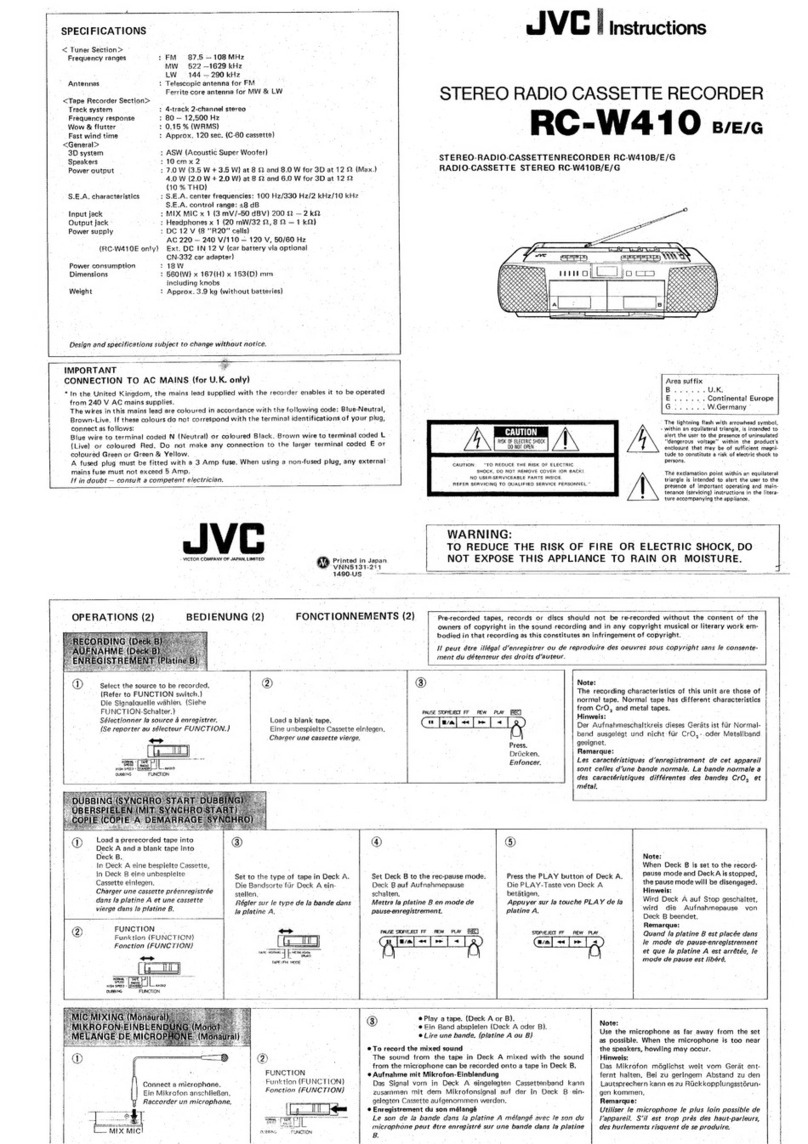

Specifications

........

0.2...

ccc

ccc

2

F@atu

res

cannes

cese

dere:

a

eta

eae

aeeeg

aeie

we

ecwree

ea

Beas

3

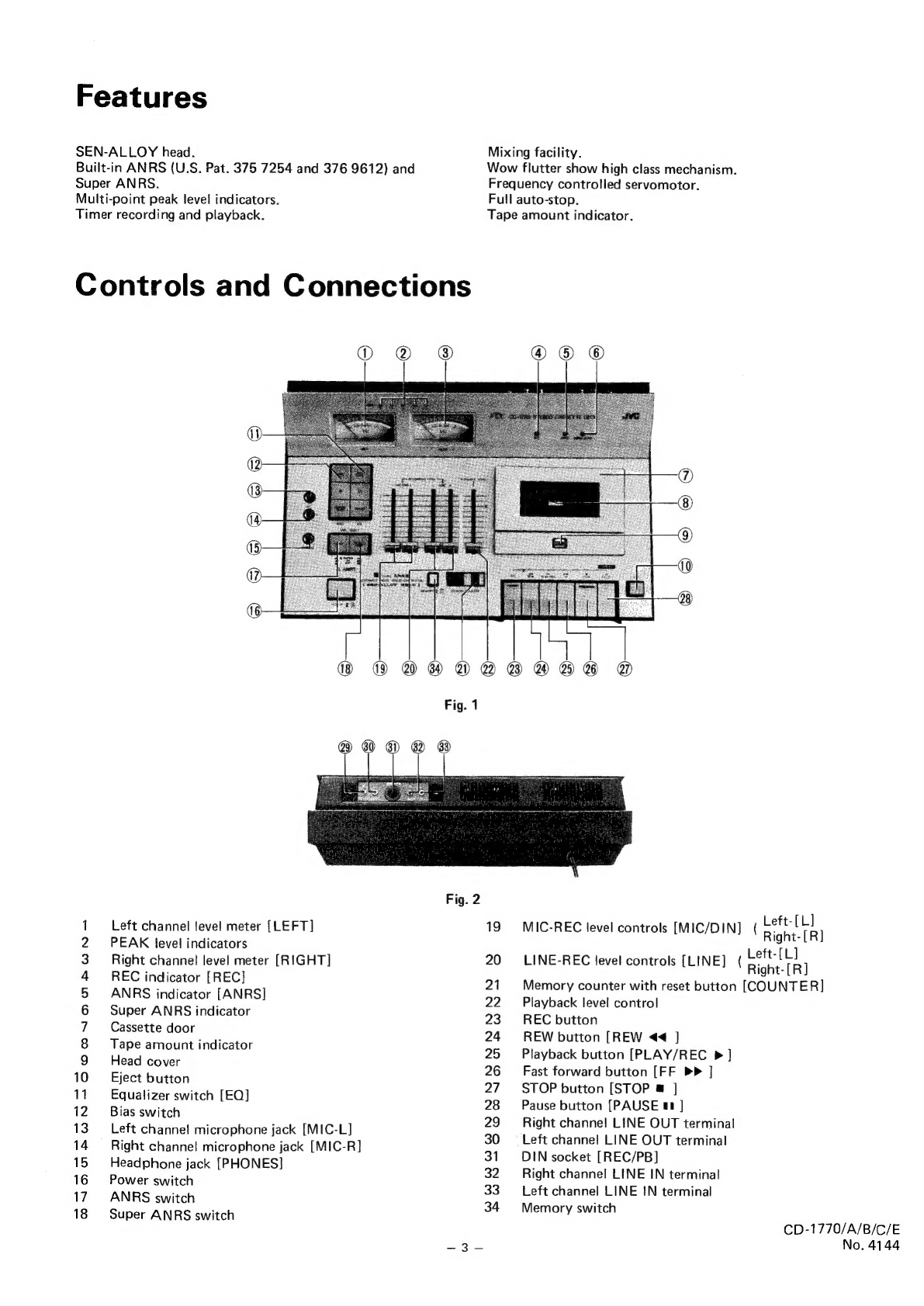

Controls

and

Connections

............0000000e008

3

Main

Parts

Removing..............2000eeeeeees

4

Enclosure

Assembly

..........000cc

ce

eeeeues

4

Electrical

Parts

2.5.02.

ic

uiweeeke

dew

en's

6

5

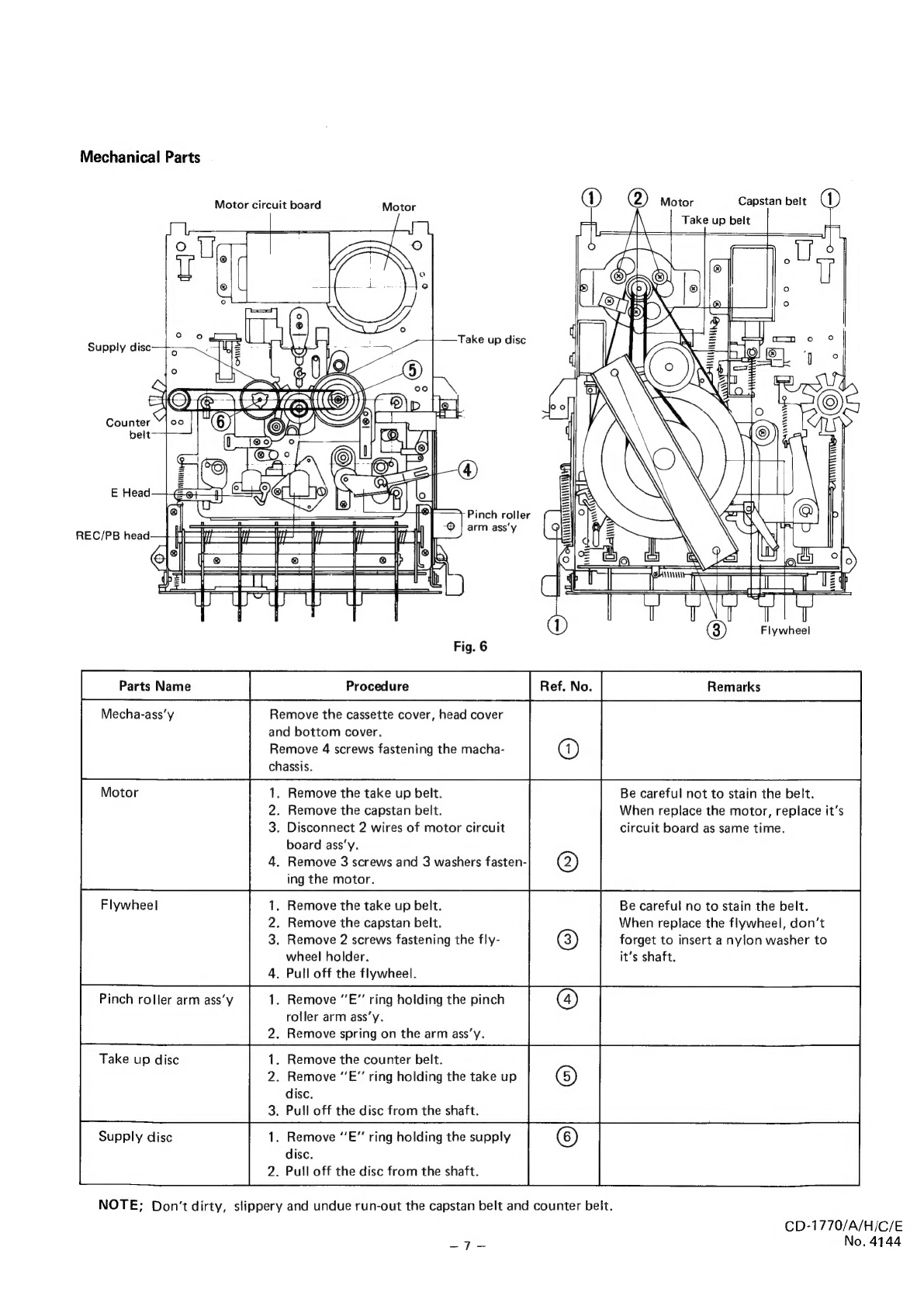

Mechanical

Parts

..............0000

cece

eeees

6

Main

Adjustments

...........

2.00

c

eee

eee

eens

7

Trouble

Shooting

Guide

..............

00

eee

eeee

12

Maintenance

..........

2...

cc

cece

eee

eee

ees

13

Block

Diagram...

0.2...

...

ccc

eee

eens

14

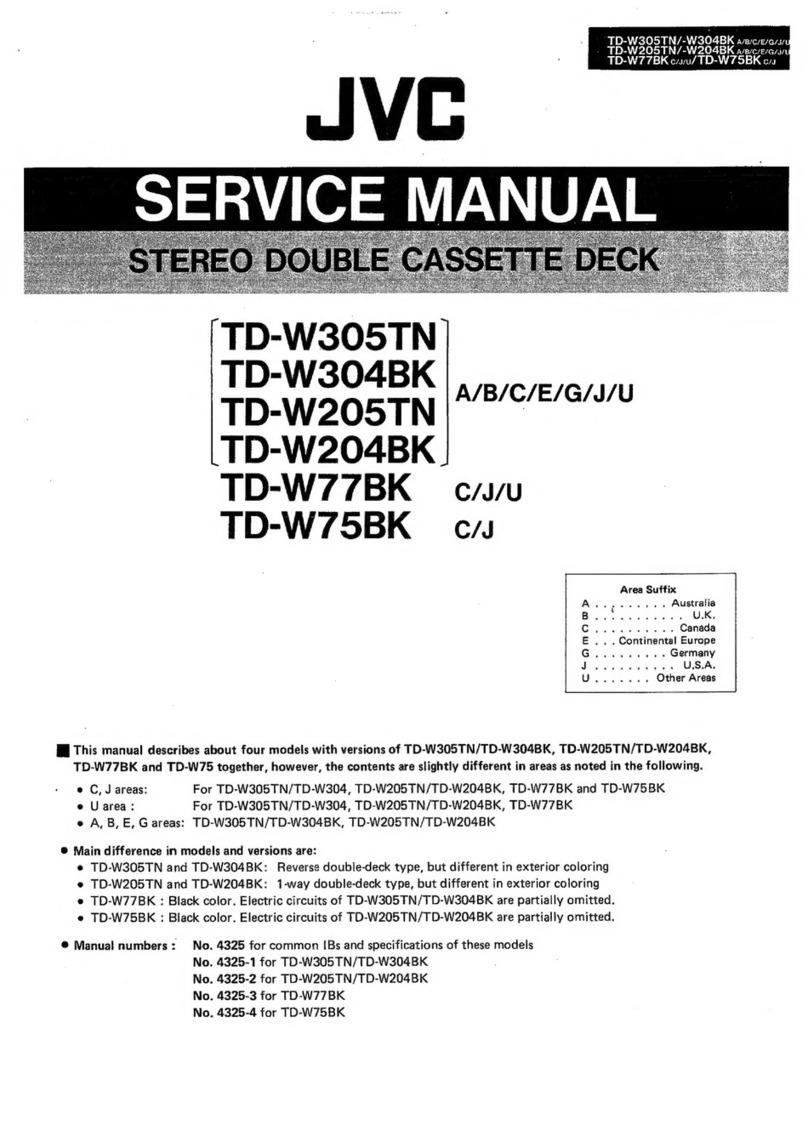

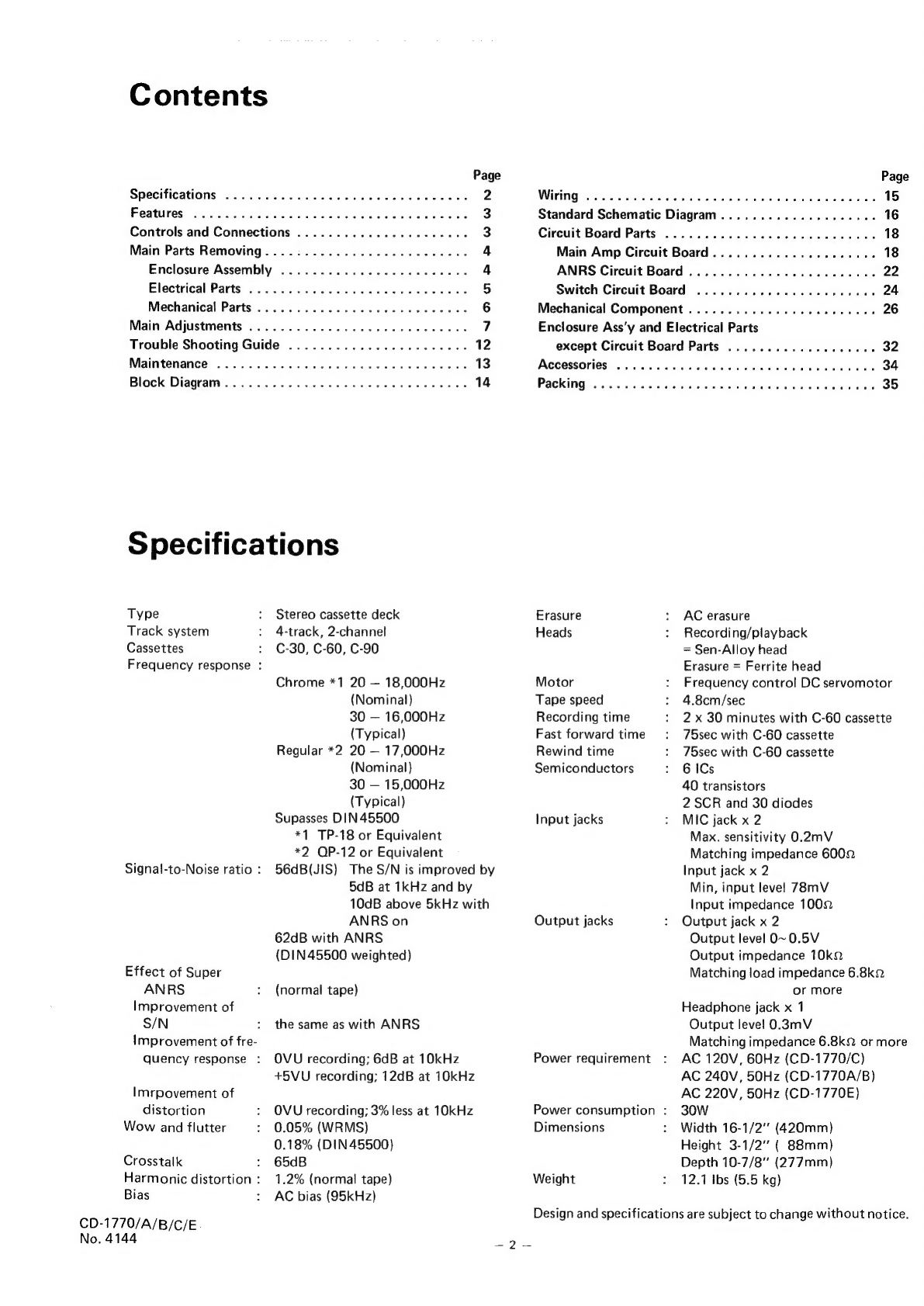

Specifications

Type

Stereo

cassette

deck

Track

system

4-track,

2-channel

Cassettes

C-30,

C-60,

C-90

Frequency

response

:

Signal-to-Noise

ratio

:

Effect

of

Super

ANRS

Improvement

of

S/N

:

Improvement

of

fre-

quency

response

:

Imrpovement

of

distortion

Wow

and

flutter

Crosstalk

Harmonic

distortion

:

Bias

z

Chrome

*1

20

—

18,000Hz

(Nominal)

30

—

16,000Hz

(Typical)

Regular

*2

20

—

17,000Hz

(Nominal)

30

—

15,000Hz

(Typical)

Supasses

DIN

45500

*1

TP-18

or

Equivalent

*2

QP-12

or

Equivalent

56dB(JIS)

The

S/N

is

improved

by

5dB

at

1kHz

and

by

10dB

above

5kHz

with

ANRS

on

62dB

with

ANRS

(DIN45500

weighted)

(normal

tape)

the

same

as

with

ANRS

OVU

recording;

6dB

at

10kHz

+5VU

recording;

12dB

at

10kHz

OVU

recording;

3%

less

at

10kHz

0.05%

(WRMS)

0.18%

(DIN45500)

65dB

1.2%

(normal

tape)

AC

bias

(95kHz)

Page

Wiring

S622

Hit

eta

bt

aioe

Se

aie

te

15

Standard

Schematic

Diagram...............20005

16

Circuit

Board

Parts

............02

cece

eee

eeeee

18

Main

Amp

Circuit

Board.

...........

0000

cca

ee

18

ANRS

Circuit

Board

...............00000euee

22

Switch

Circuit

Board

..........

00000

e

ences

24

Mechanical

Component

..............00000eeeas

26

Enclosure

Ass’y

and

Electrical

Parts

except

Circuit

Board

Parts

.............0.0000.

32

ACCOSSOFICS

65

a

oie

cisie-bhe

aWewcs

ainate

o

Pree

che

ates

34

Pack

ing

220i

esavaretag

ates

GA

ato

iis

Ge

ahs

Ae

a

35

Erasure

AC

erasure

Heads

Recording/playback

Motor

Tape

speed

Recording

time

Fast

forward

time

Rewind

time

Semiconductors

Input

jacks

Output

jacks

Power

requirement

Power

consumption

:

=

Sen-Alloy

head

Erasure

=

Ferrite

head

Frequency

control

DC

servomotor

4.8cm/sec

2

x

30

minutes

with

C-60

cassette

75sec

with

C-60

cassette

75sec

with

C-60

cassette

6

ICs

40

transistors

2

SCR

and

30

diodes

MIC

jack

x

2

Max.

sensitivity

0.2mV

Matching

impedance

6002

Input

jack

x

2

Min,

input

level

78mV

Input

impedance

1002

Output

jack

x

2

Output

level

0~

0.5V

Output

impedance

10k

Matching

load

impedance

6.8ka

or

more

Headphone

jack

x

1

Output

level

0.3mV

Matching

impedance

6.8k9

or

more

AC

120V,

60Hz

(CD-1770/C)

AC

240V,

50Hz

(CD-1770A/B)

AC

220V,

50Hz

(CD-1770E)

30W

Dimensions

Width

16-1/2"'

(420mm)

Height

3-1/2’

(

88mm)

Depth

10-7/8”"

(277mm)

Weight

12.1

Ibs

(5.5

kg)

Design

and

specifications

are

subject

to

change

without

notice.

CD-1770/A/B/C/E

a

ee

m

No.

4144