JVC TM-1400U(CV) User manual

Other JVC Monitor manuals

JVC

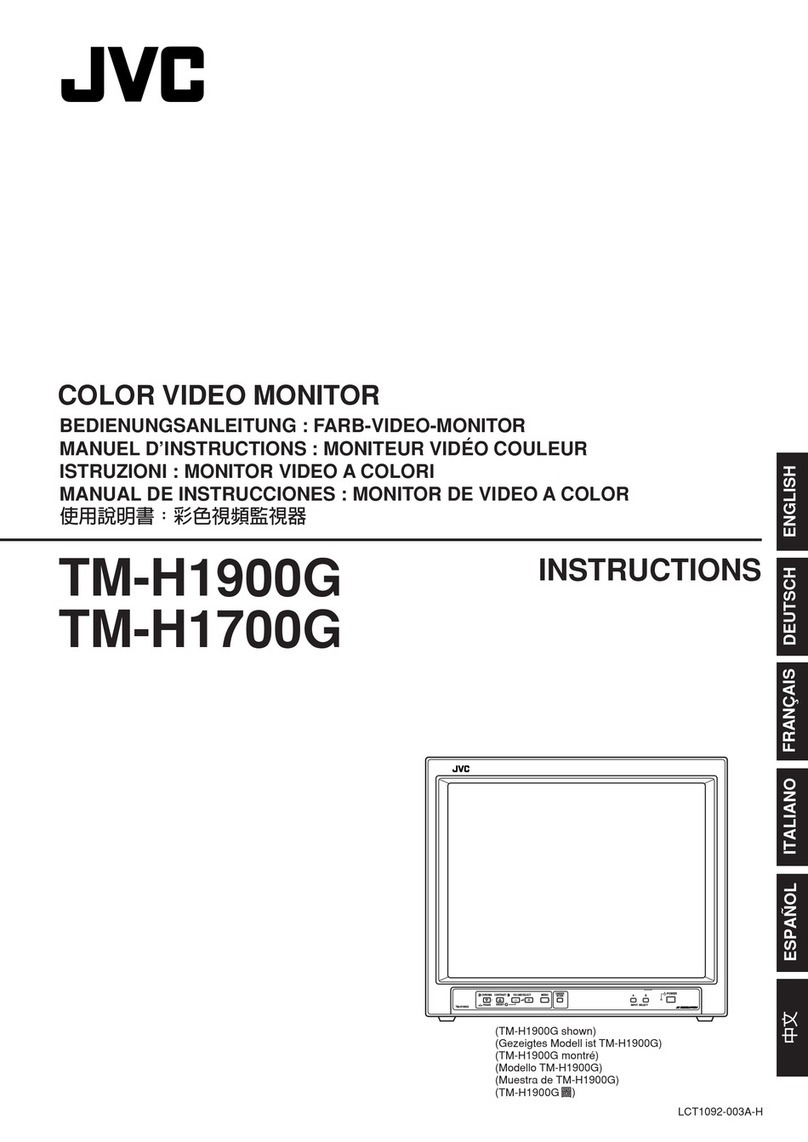

JVC TM-H1700G User manual

JVC

JVC I Art PD-42X795 User manual

JVC

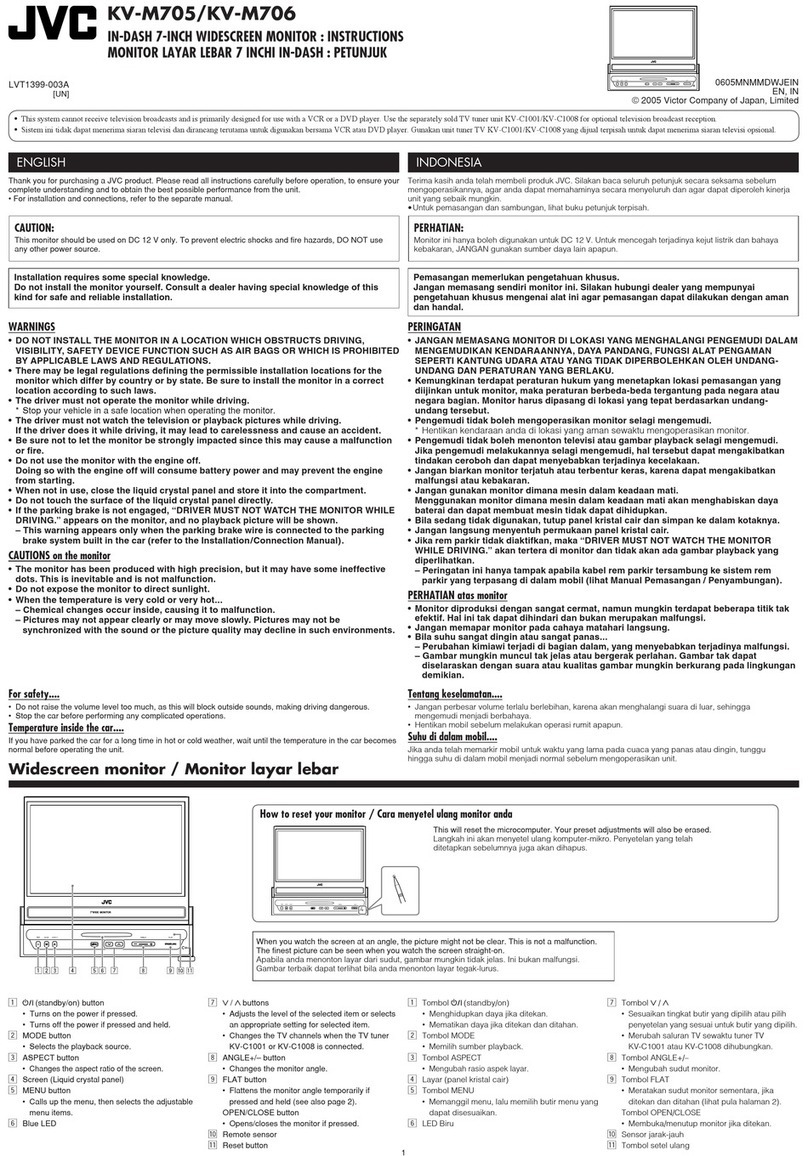

JVC KV-M705 User manual

JVC

JVC KW-M788BH User manual

JVC

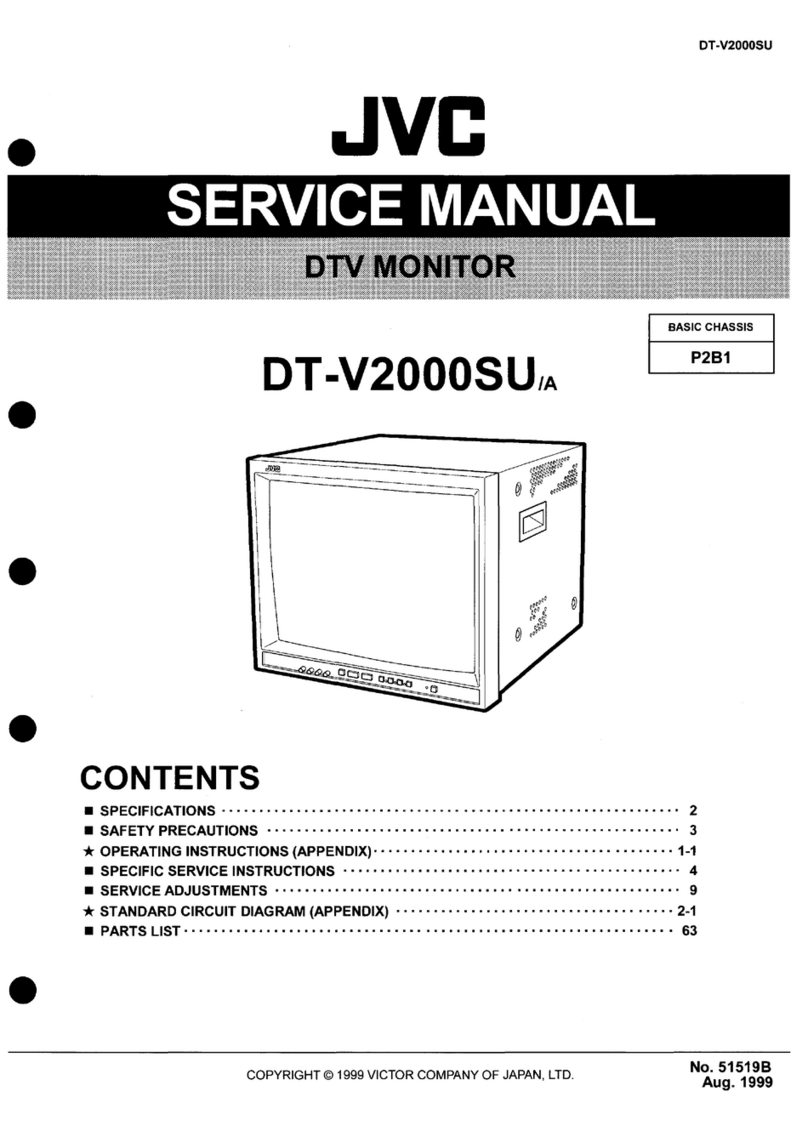

JVC DT-V2000SU - Dtv Monitor User manual

JVC

JVC DT-V100CGU - Hdtv Multi-format Monitor Installation guide

JVC

JVC KW-M180BT User manual

JVC

JVC KW-V940BW User manual

JVC

JVC DT-E21L4 User manual

JVC

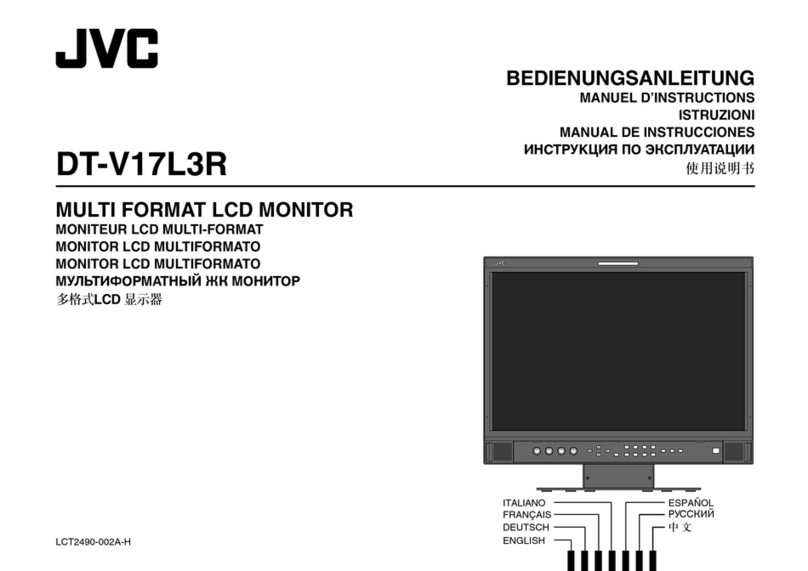

JVC DT-V17L3R User manual

JVC

JVC KW-V31BT User manual

JVC

JVC TM-H1900G User manual

JVC

JVC TM-H1700GU - Color Monitor User manual

JVC

JVC TM-H1750CG User manual

JVC

JVC TM-H1750CG User manual

JVC

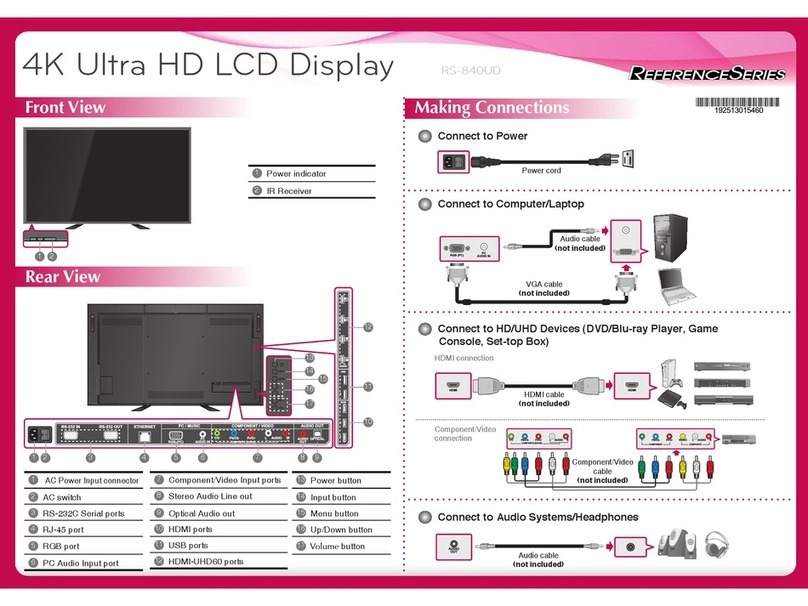

JVC RS-840UD Installation guide

JVC

JVC TM-A101G/E User manual

JVC

JVC KW-M875DBW User manual

JVC

JVC GD-V422U User manual

JVC

JVC GM-H40L2A User manual