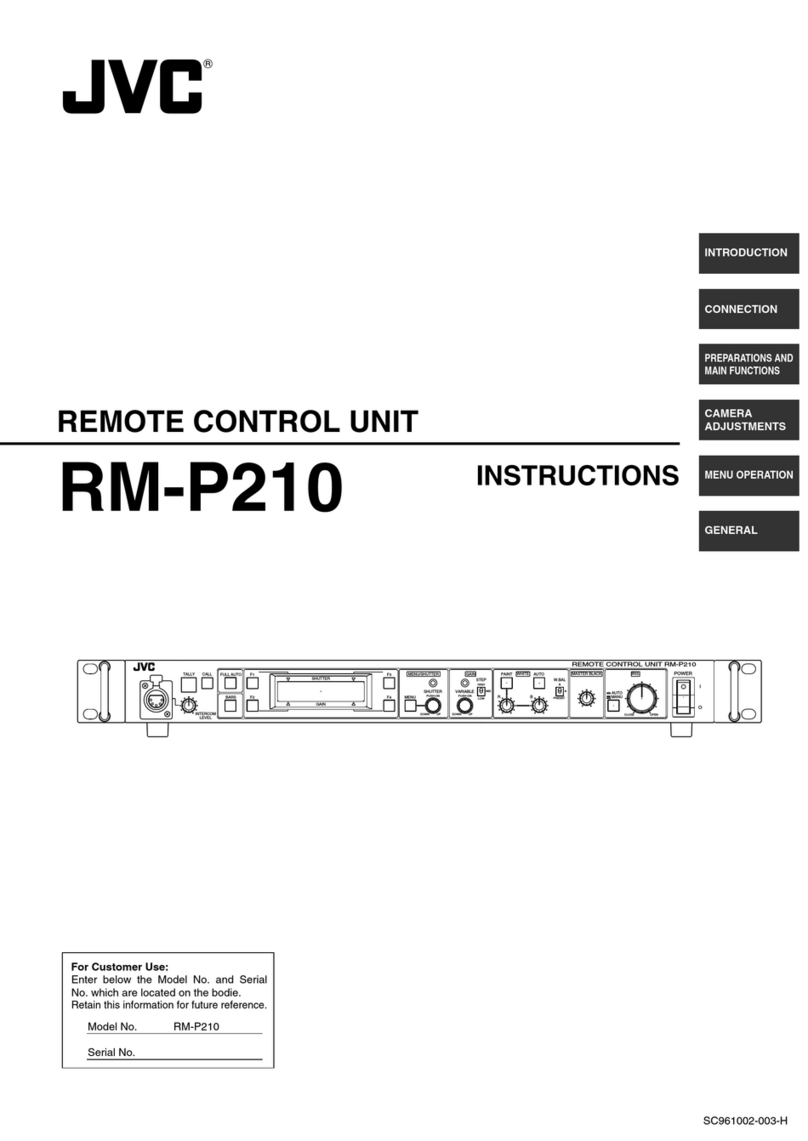

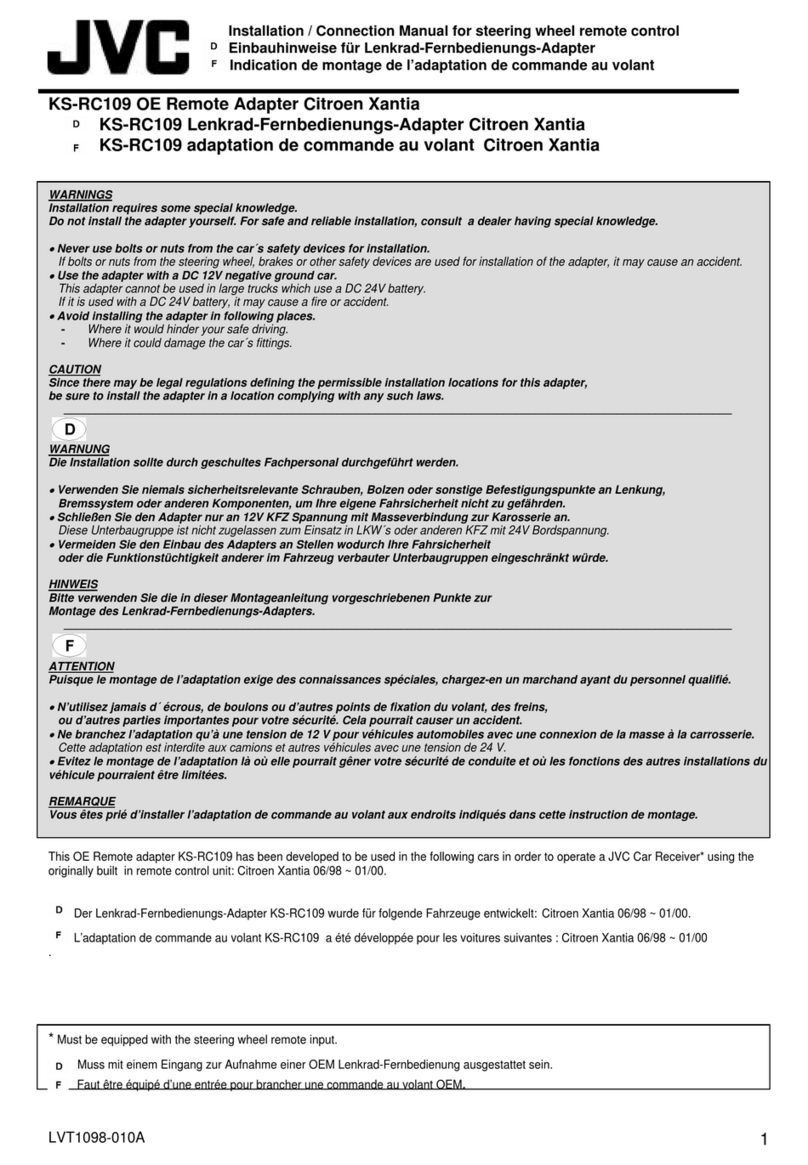

1-5

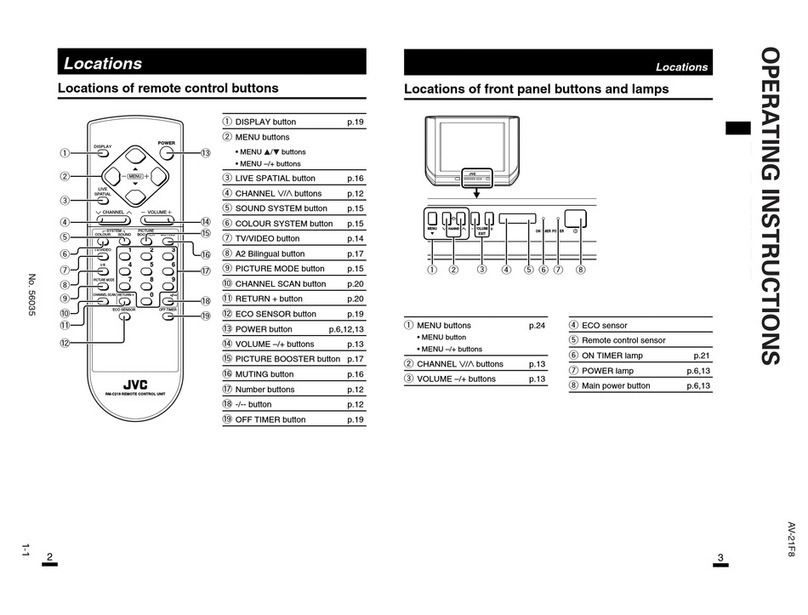

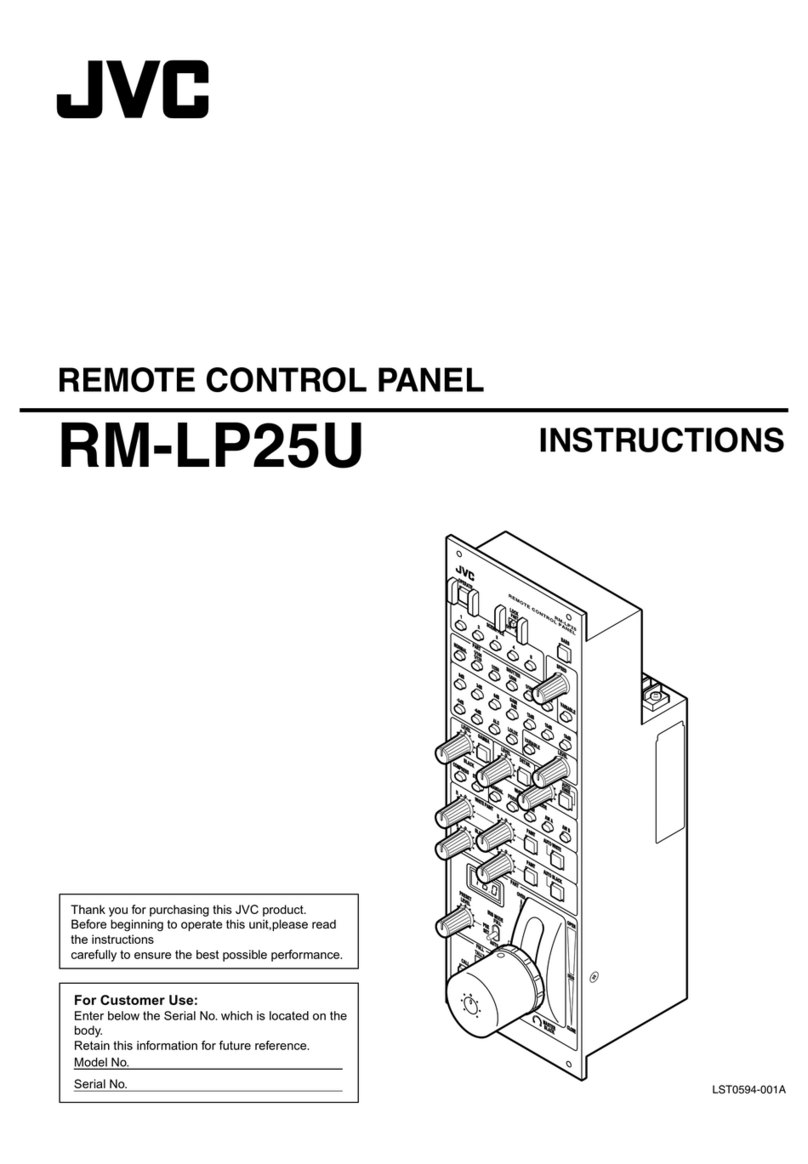

Turn this VR and confirm that data varies between 0 and 255.

Turning clockwise should increase the value.

This VR also controls the LCD contrast. It is Normal at the

center. Turning the VR clockwise should increase contrast

and counter-clockwise should decrease it. The LCD back light

should be OFF at the most clockwise position.

Turn this VR and confirm that data varies between 0 and 255.

Turning it clockwise should increase the value.

This VR also controls the SC FINE data output.

Turn this VR and confirm that data varies between 0 and 255.

Turning it clockwise should increase the value.

This VR also controls the LENGTH HF data output

Turn this VR and confirm that data varies between 0 and 255.

Turning it clockwise should increase the value.

This VR also controls the LENGTH Y data output

Turn this JOG and confirm that data is switched to 5M, 20M,

50M and 100M. Turning it clockwise should increase the

value.

The initial value when the unit is turned ON is 20M.

This JOG also checks the JOG rotation and JOG hardware

when LENGTH is selected in addition to SHUTTER JOG

check.

Turn JOG and confirm that data is switched to 0°, 90°, 180°

and 270°. Turning clockwise should increase the value.

The initial value when the unit is turned ON is 0°.

This JOG also checks the JOG rotation and JOG hardware

when SC COARSE is selected in addition to V.GAIN JOG

check.

Operate this SW and confirm that A, B and PRE are displayed

correctly when the SW is in the corresponding position.

This SW should also vary ASPECT internally: When A (16:9),

B (Letter Box) and PRE (4:3) are displayed, the internal mode

should vary accordingly.

Operate this SW and confirm that LOW, MID and HIGH are

displayed correctly when the SW is in the corresponding

position.

This SW should also vary the supply voltage to the camera

internally: When LOW (15 V), MID (17 V) and HIGH (19 V) are

displayed, the internal voltage should vary accordingly.

When the unit is

turned ON, 15 V is

output regardless

of the position of

this SW, until this

SW is changed to

another position.

Set each SW to ON and OFF and confirm that the

corresponding display changes to H (ON) or L (OFF).

IRIS

128

M.BLACK (SC FINE)

128

WHITE Bch(C)

128

WHITE Rch(Y)

128

SHUT JOG(LENGTH)

20M

V.GAIN JOG(SC)

0°

W.BAL(ASPECT)

PRE(4:3)

GAIN(VOLT)

LOW(15V)

DIP SW12345678

LLLLLLLLL

Check Point Check DetailsLCD Display Remark

VR

JOG

SW

DIP

SW

IRIS

MASTER

BLACK

WHITE Bch

WHITE Rch

SHUTTER JOG

V.GAIN JOG

W.BAL

STEP GAIN

SW 1 to 8

With the checking of VR, JOG dials and switches, operating a control causes information to be displayed on the LCD. The LCD

display is retained until other information is displayed on the LCD. However, pressing the CALL button displays the initial display.

1.3.4 Adjustment Mode

The Adjustment mode is detailed in the description of the adjustment procedures. Please see section 2.2.