4

Install Handle

Swing Door

1. AttachtheG-152handletothehubwheretheoldhandlewasremoved,usingthepinincludedin

the kit. Insert the pin from the front side of the locking bar.

2. Gainaccesstotherearofthepin.Insertwasherandrivetincludedinthekit.Securetherivetin

positionusingthepoprivetgun.

Note: Ifinstallingonadoorwithdoubleverticallockingbars,installonthelockingbarclosest

to the hinges.

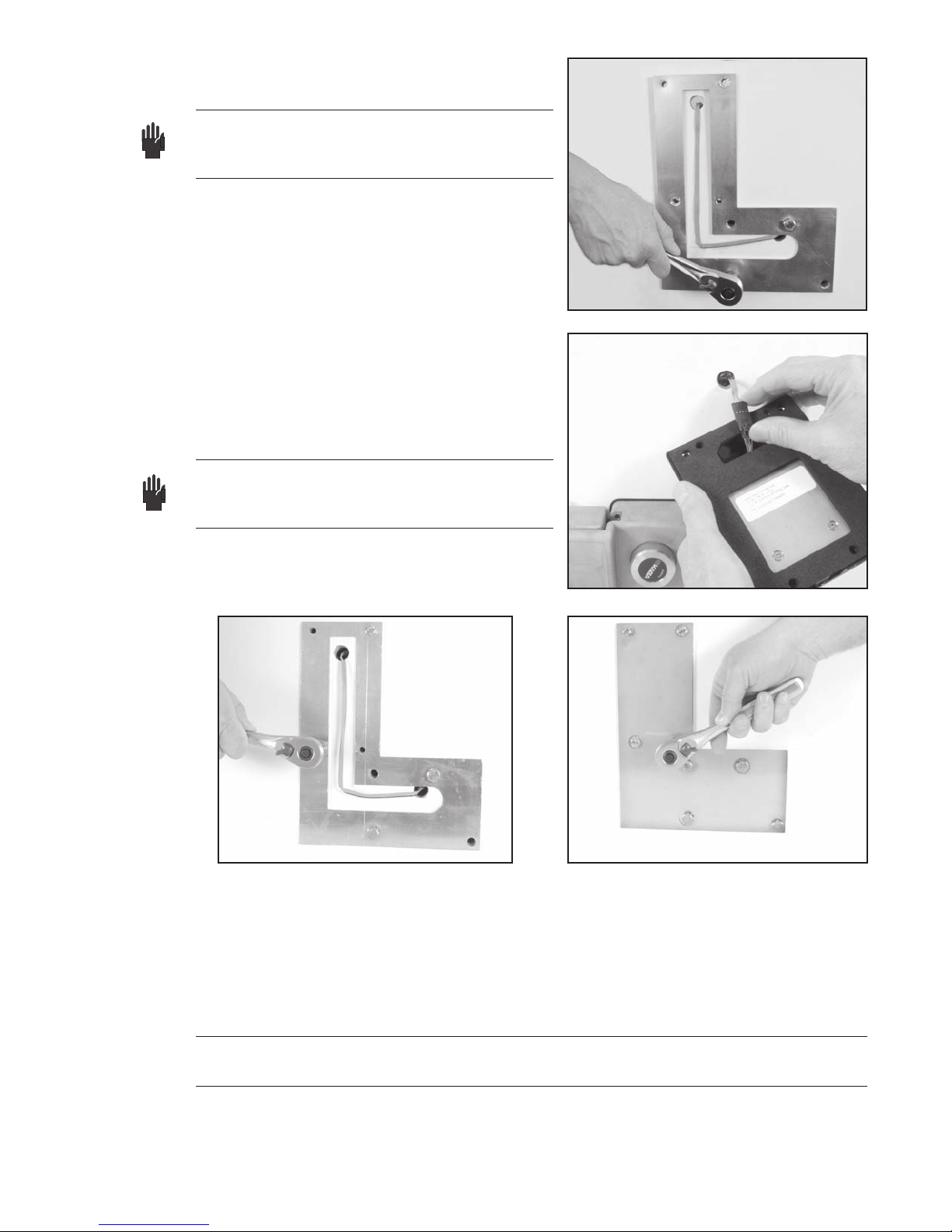

Roll-Up Door

1. Withthedoorclosed,alignthedoorhandleassembly"J"hookwiththecenterpin/plateofthelatch

box.Operatehandle(open/close)toensurecorrectpositionwithinthelatchbox.

2. Ensurethehandleislevel.Usetheatendofthehandle.(Seegure8.)

3. Using the handle assembly mounting bracket as a template, mark (center punch) the location of

the mounting holes.

4. Drillthehandleassemblymountingholesusingan8mm(5/16")drillbit.

5. Insert and seat carriage bolts into supplied handle assembly. Seat carriage bolts by using a hammer

todrivetheboltsintothemountingplate.

6. Mount handle assembly to door and secure from the inside with washer/lock washer/nuts

provided.

Note: Ifnecessary,useahacksawtoremove

excess bolt length and grind any

resulting sharp edges.

Prep Door for Lock Body

1. Using the new handle, close the door(s) fully,

ensuring correct shutting for closed position.

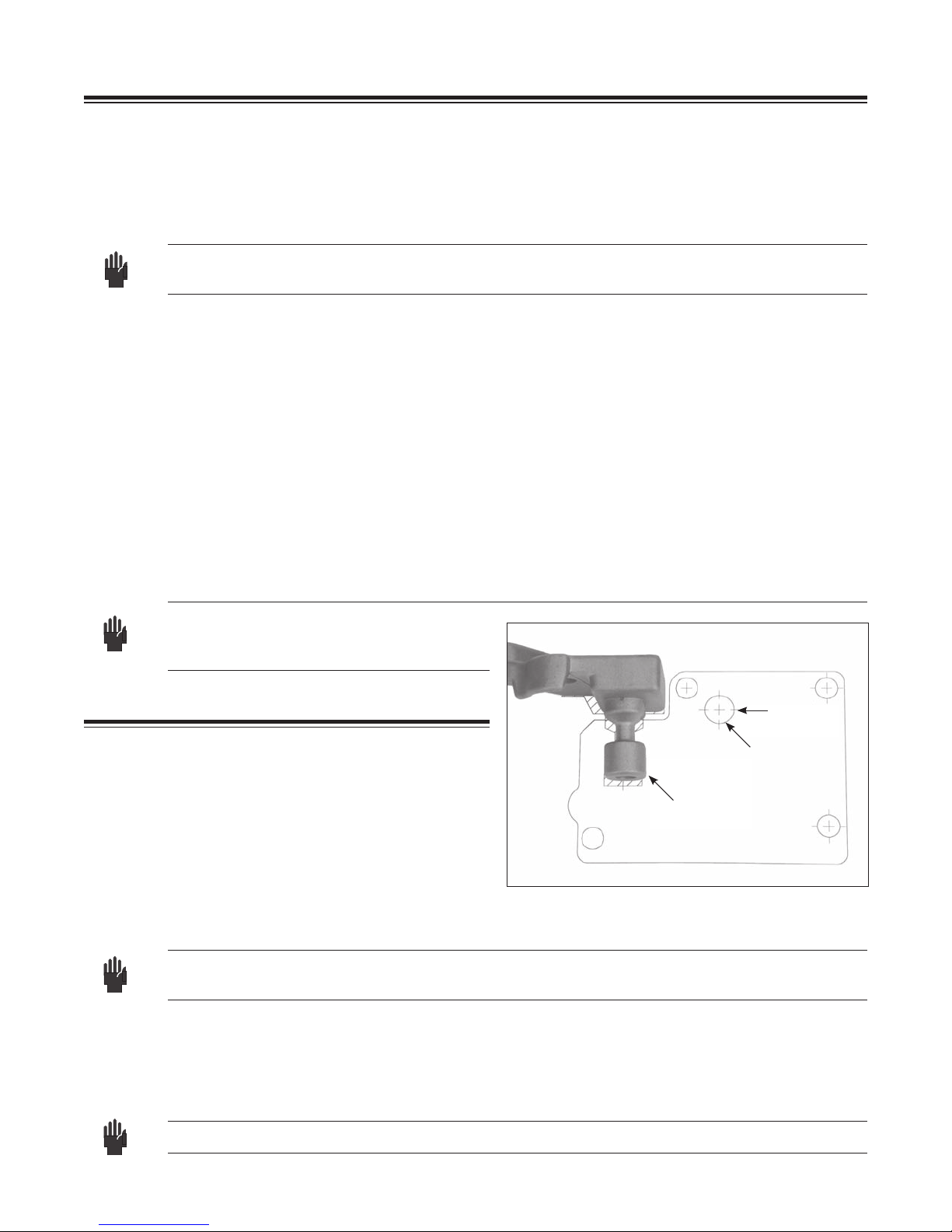

2. Aligntemplaterelativetothelockingpinon

thehandle.(SeeFigure8.)

3. Use tape to secure the template to the door.

4. Place the lock body over the coordinating

location on the template and rotate the handle

to ensure that it clears the lock body. If not, readjust the template.

Note: If the handle becomes locked in position, connect the cable from the input unit to the lock

bodyandperformtheOperationalCheck(p.7)tounlockandliftthehandle.

5. Center punch all four mounting holes and cable routing hole.

6. Removethetemplate.

8. Drillthefouroutsidelockcasemountingholesusinga10mm(3/8")drillbit.

9. Drillthecableroutingholeusinga16mm(5/8")drillbit.

Note: Ensurethatthedrilliskeptstraightwhendrillingtheholes.

Fig. 8 - Align Template to Handle

FlatonHandle

Locking PIN

Electronic

LockOnly

Cable

Routing Hole