Table of Contents

INTRODUCTION ........................................................................................................... 1

Installation Overview ............................................................................................................... 1

Basic Tools and Materials Needed .......................................................................................... 1

Door Handing .......................................................................................................................... 2

Templates ................................................................................................................................ 2

Rim Exit Device ....................................................................................................................... 2

CDX-09 Lock Assembly .......................................................................................................... 2

Dial Ring Mounting Template .................................................................................................. 2

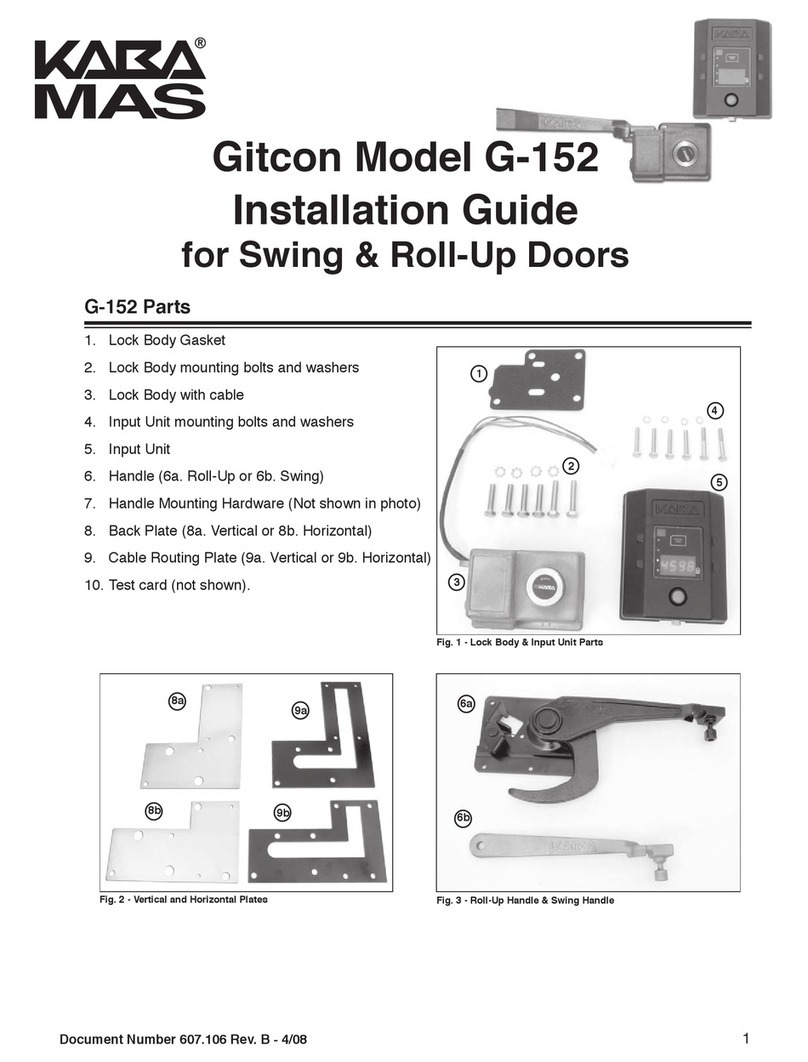

PARTS CHECK .......................................................................................................... 3

Packaging................................................................................................................................ 3

Rim Exit Device Box ............................................................................................................... 4

CDX-09 Box ............................................................................................................................ 6

Lock Parts for Installation ....................................................................................................... 6

Installation Kit Contents .......................................................................................................... 6

ELECTRIC LOCKING TRIM SPECIFICATIONS ...................................................................... 7

RDS - Power Supply Control Module ...................................................................................... 7

DOOR PREPARATION................................................................................................... 8

Mark Rim Exit Device and Strike Locations ............................................................................ 8

Rim Exit Device Template .......................................................................................................9

Install CDX-09 Lock Strike ......................................................................................................9

CDX-09 Lock Assembly Template ........................................................................................ 10

Drill Holes for Rim Exit Device and Outside Lever Trim ........................................................ 10

Drill Holes for CDX-09 Lock Assembly ................................................................................. 10

CDX-09 Dial Ring Mounting Template ................................................................................... 10

RIM EXIT DEVICE / OUTSIDE LEVER TRIM ..................................................................... 11

Hardware Preparation ........................................................................................................... 11

Cut Lever Spindle and Rim Cylinder Tailpiece to Length ..................................................... 11

Determine Rim Exit Device Length, Cut to Length and Drill End Cap Mounting Hole ........ 11

Installation ............................................................................................................................. 13

Mount Rim Exit Device and Outside Lever Trim ................................................................... 13

Mount Strike .......................................................................................................................... 14

ELECTRIC LOCKING TRIM & RDS INSTALLATION ........................................................... 15

Installation Procedure ............................................................................................................ 15

System Schematic ................................................................................................................15

RDS-2 Specifications ............................................................................................................16

Operational Test for FSE (Fail Secure) Devices.................................................................... 16