COVER

LOWERMOUNTING

PLATE

WITHBLAST

FIG.

4

5.

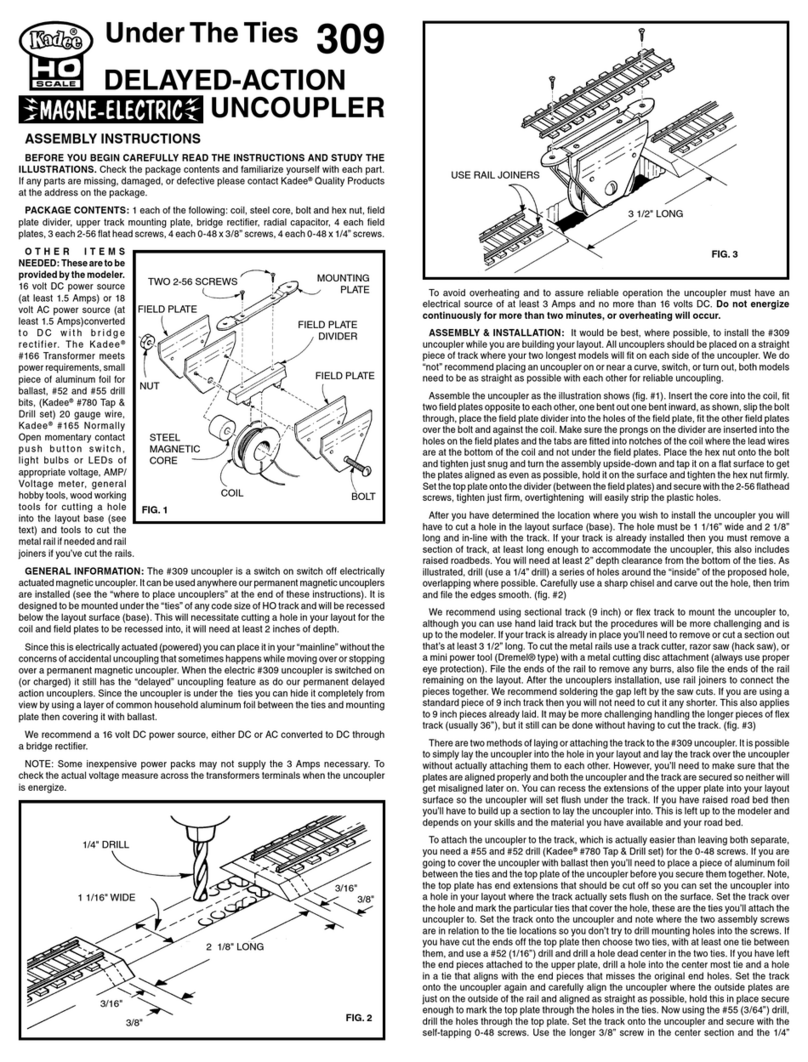

After

all

partshavebeenprepared,assemble

in

sequence

as

illustrated

in

Fig.

3.

Install

metalrailjoiners

atthe

ends

ofthe

rails

onthe

layout,pushthem

asfar

back

as

they'll

go.

Loweruncouplerassemblyintoplace(Fig.

3)and

pull

rail

joinersoverrailjoints.

6.Ifyou

haveinstalleduncoupler

on

roadbed,fill

the

gapsbetweenlowertrackmountingplate

and

layoutbasewithsections

of

roadbedtrimmed

to

fit.

Youmay

wish

toadd

someglue

to

thesesections

for

rigidity.

Ifyou

have

installed

uncouplerdirectly

to

layoutbase,

youmay

wish

to

spike

or

gluelowertrackplatedown

for

strength.Now,coverplatewithballastglued

in

place

withwhiteglue.

See

Fig.4.

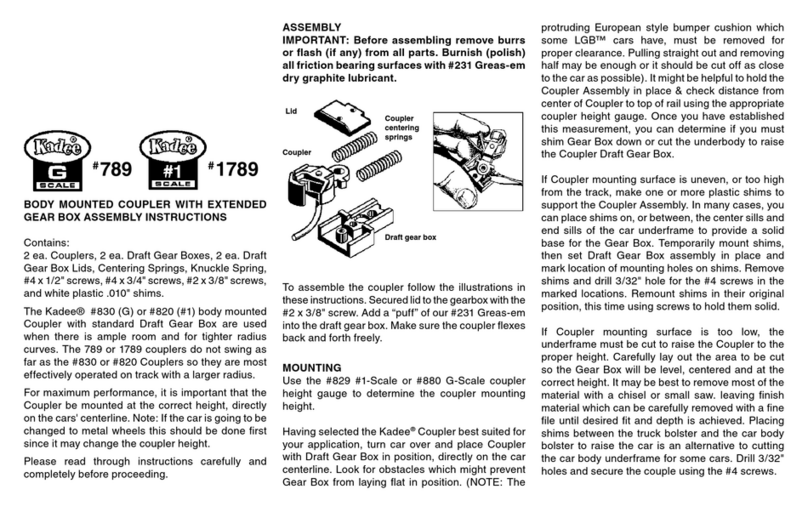

ASSEMBLY

MODIFICATIONS:

Althoughthisuncoupler

is

designed,

asis,foruse

with

the

largerrailsizes,

itcanbe

modified

to

be

compatiblewithsmallerrail-evendown

to

code

40

size.This

is

accomplished,

in

simple

terms,

by

lowering

the

fieldplate/coreassembly

and

thinningdown

the

uppertrackplate

so

thatthey

are

evenwith

the

height

ofthe

rail.

1.

Assembleuncouplercompletelyminuslowertrackmountingplate

and

track.

Be

sure

and

use

the

included.010"thickwashers

as

shown

in

Figs.

1and3.

2.Add

extrafiberwashers(notincluded)between

the

uppertrackmountingplate

andthe

field

platedivider.

The

thickness

of

thesewashers

canbe

determined

by

subtracting

the

height

of

the

rail

youare

usingfrom

the

thickness

ofthe

uppertrackmountingplateends.

For

example,

theendofthe

upper trackplate

is

.055"thick

and

let's

saythe

rail

you

want

to

use

is

code

40

(.040")high.055"minus.040"equals.015".

Use

washer(s)equal

to

.015"thick.

3.

Afterassembly,notethat

thetopofthe

fieldplates

isnow

lowerthan

the

ends

ofthe

upper

track

plate.

Take

a

sandingblock,firstwithcoarsesandpaper,

and

slowlysanddownthese

ends

until

almost

evenwith

thetopofthe

fieldplates.Finishsandingdownevenusing

a

fine

grit

sandpaper(Fig.

A.)

COUNTER

SINK

WITH

#20

DRILL

FIG.

B

4.

Finishmodification

by

taking

a #20

drill

and

countersinking

theend

holes

inthe

mounting

plate

as

shown

in

Fig.

B.

Twistdrillslowly

by

handusing

a

shavingactionratherthancutting

action

to

preventgoing

alltheway

thru

the

hole.

WIRING:

After

installinguncoupler

inthe

track,it'stime

for

hooking

itup

electrically

for

use.

You

will

have

to

wire

the

uncouplercoil

totheDC

side

ofa

powerpackthru

a

pushbuttonswitch(not

included)

the

Kadee#165(N.O)normallyopenpushbuttonswitches

are

recommended,

see

Fig.

X.The

pushbuttonswitchneeds

tobea

singlepole,singlethrow(SPST)momentary

contacttype

and

should

be

able

to

handle

at

least

3

amp,8-12volts

DCthe

Kadee#165meet

the

requirements.

For

additionalinformation,

refer

to

Kalmbachbook"How

to

Wire

Your

Model

Railroad"

by

LinnWestcott.Pushbuttonswitches

are

availablethruhobbyshops

or

radio/

electronicsstores.

Use

insulated

#20AWG

wire

for

hook

up.Get

colorcodedwire

to

avoidcross-wiring. Study

wiring

diagram(Fig.

X)for

connecting

1,2,3 or

moreuncouplers.Alsokeep

in

mindthat

all

hook-up

wiresmust

be

stripped

of

insulationwherever

it

connectswithanotherwire.Wires

from

the

uncouplercoilhave

a

thincoating

of

insulationwhichmust

be

scrapped

off

whenhooking

upfor

electricalcontact.First,

runa

wire

from

oneDC

powerpack

DC

SINGLE

NORMALLY

OPEN

SWITCH

MOMENTARY

HOOK-UP14-20VOLTCONTACTPUSH

.2

AMP

BULBBUTTONSWITCH

3

AMP

POWER

PACK

DC

L2

AC

00

UNCOUPLERCOIL

20AWG

WIRES

FIG.X

2,

3

OR

MORE

SWITCH

HOOK-UP

POWER

PACK

.DER

_j3Zr^X.

NTS

WITH

o4^

SOLDER

JOINTS

WITH

ROSIN

CORE

SOLDER

terminal

straight

tooneofthetwo

wires

atthe

uncouplercoil.Twistthispowerpackwire

and

coilwiretogether.Remember

the

powerpack

hastobe

largeenough

to

provide

3

AMPs

per

uncouplerbeingused

atthe

same time. Second,

runa

wirefrom

the

power

pack

DC

terminal

tooneofthetwo

leads

atthe

pushbuttonswitch.

Twist

thispowerpack

wire

onto

the

lead.Third,twist

a

length

of

wireonto

the

otherpushbutton

lead

longenough

to

reach

the

remainingunconnectedwire

atthe

uncoupler

coil.

(Optional

light

bulb

orLED

canbe

placed

in

this

section

of

wire

as

show

in

Fig.

X to

visually

showwhen

the

circuit

is

active)

Twistthis

wire

from

the

pushbutton

and

coilwiretogether.

You

should

nowbe

able

to

operate

the

uncoupler

by

activating

the

pushbutton.Tryoutaccording

to

"Operation"section

and

then

if

desired,solder

all

twisted

wire

connectionswithrosincoresolder,1/16"size,Fig.

Y.

OPERATION:

WARNING:

Donotusethe

electricuncouplercontinually,

but

ratherintermittentlywithperiods

of

timebetweenuses.

"DO

NOT"activate

the

uncoupler

for

longerthan

"2

MINUTES"

at

one

time.Thiswillavoidpossibleoverheatingwhichwilldamage

the

uncoupler.

To

uncouple,pull

or

pushcoupledcars/locomotives

toa

stoppedposition

ata

pointwhere

the

connected

couplers

are

directly

over

the

uncoupler,

allowing

slack

to

occurbetween

the

couplers.

Energize.the

uncoupler(pushbutton),Knuckleswillopen,Withdrawslightly

to

disengage

the

couplers.

Theywillstayopen

as

long

asthe

uncoupler

is

activated(energized).

Nowyoucan

enter

overuncoupleragain,couplers

arein

"delayed"positionallowing

youto

push"spot"

the

car

as

long

asyou

continue

the

pressureagainst

the

opencouplers

to

desiredlocation.Release

the

(pushbutton)aftercouplers

areinthe

"delayed"position

oryouare

finisheduncoupling.

Enter

over

uncoupler

again,

couplers

arein

delayed

position

allowing

pushing

of

car(s)

without

causing

re-coupling.

Withdraw,

leaving

uncoupled

car(s)

on

desired

track.

Couplers

automatically

return

to

normal

coupling

position.

Quality

Products

Co.673

Avenue

C,

061113

White

City,

OR

97503-1078

Made

inthe

U.S.A.

©2013,

Kadee'

QualityProducts

Co.