Note: One of the gear boxes has a large hole in

the shank and the other has been machined at an

angle on the shank. The coupler with the medium

offset is used with the draft gear box that has the

large hole located in its shank and will be mounted

at the front of the locomotive. See Fig.1. The coupler

with the large offset is used with the draft gear box

that has been machined and is to be mounted at the

rear of the locomotive. See Fig.2. When working on

locomotives or cars they must often be turned upside

down or on their sides. Always place a protective mat

underneath them, and protect any protruding detail

parts which could be damaged. Remove any flash or

burrs from parts with a file or an X-acto®knife.

MOUNTING

Front coupler:

1. Remove the old existing coupler.

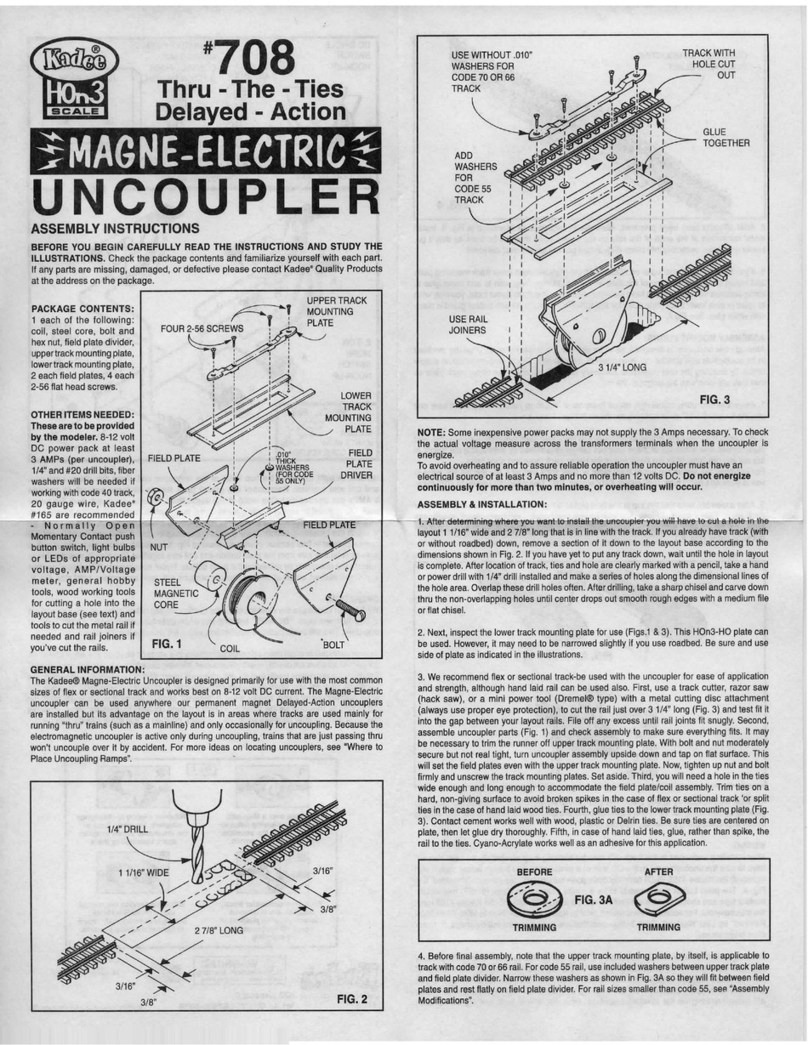

2. Refer to the exploded view in Fig.3 to familiarize

yourself with coupler mounting parts and installation

positions. There are two large diameter washers in

this packet, one (1) thick and one (1) thin. Place the

thin washer onto the locomotive's coupler mounting

post and slide it down until it rests on top of the three

gussets located on the post. If the washer does

not slip onto the coupler mounting post there may

be excessive paint on the post. This paint can be

removed by scraping the post with an X-acto®knife.

The washer should not fit too loosely.

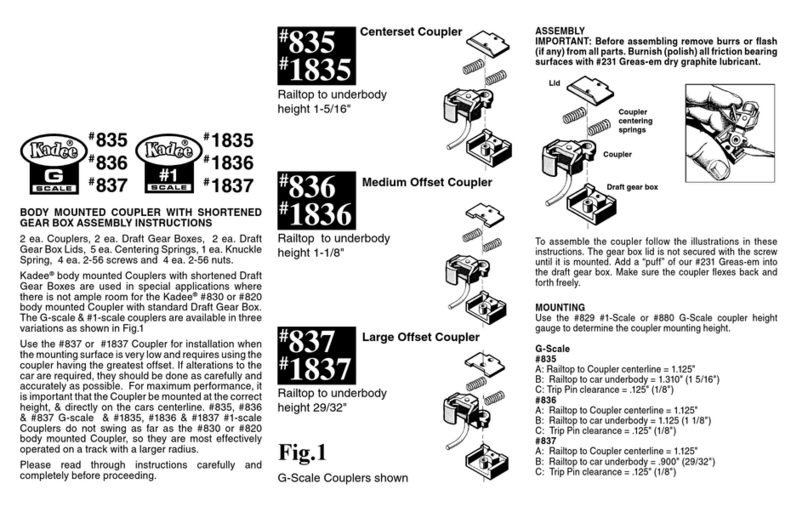

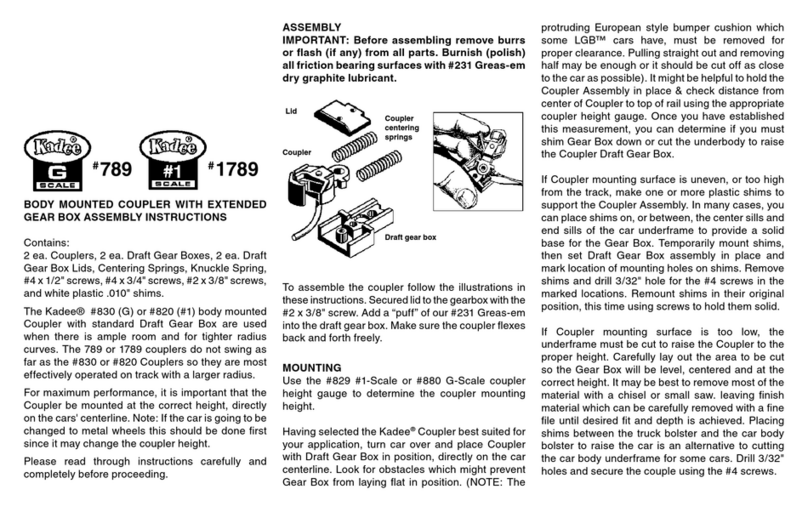

ASSEMB LY

IMPORTANT: Before assembling remove any

burrs or flash (if any) from all parts. Burnish

(Polish) all friction bearing surfaces with #231

Greas-em dry graphite lubricant.

To assemble the coupler follow the illustrations in

these instructions. Make sure the gear box lid is

tightly secured with the screw. Add a “puff” of our

#231 Greas-em into the draft gear box. Make sure

the coupler flexes back and forth freely.

Lid Coupler

centering

springs

Coupler

Draft gear box

Screw

3. Slip the assembled coupler unit through the

opening of the locomotive pilot and tilt the coupler

unit at a slight angle to position the large hole in the

draft gear box shank over the mounting post. Slide

the shank down the post to rest on the thin washer

and then level coupler unit.

4. The thick washer can now be placed on the post

and over the previously installed draft gear box

shank.

5. Position the flat angle spring over the thick washer,

centering the hole in the spring leg over the original

coupler mounting screw hole in the post. Make

certain that the other spring leg is pointing down

behind the end of the draft gear box shank.

6. Place the small washer on top of the flat angle

spring and secure with the original coupler mounting

screw that was removed previously, Make certain

that the draft gear box is centered in the locomotive

pilot opening while tightening the mounting screw.

7. Test the centering action of the draft gear box; it

should move freely from side to side and re-center

itself. If the coupler unit does not center properly, it

may be helpful to loosen the mounting screw and

push slightly forward on the back leg of the flat angle

spring while retightening the screw. If the flat angle

spring does not tighten down properly, remove and

file one or both of the large washers until it will do so.

If more side swing of the coupler is desired, the sides

of the draft gear box or pilot opening at the front of

the locomotive can be modified by carefully cutting

or filing away the excessive material that interferes

with the desired swing. Caution must be exercised

against removing to much material. This would

impair the performance of the coupler.

793 / 1793 Ins.

Rear Coupler:

1. Remove the old existing coupler.

2. Place the new Kadee®coupler unit with the large

offset in the same position as the old coupler. Secure

with the previously remove 1 original mounting screw

or use the supplied No.4 x 3/8" screw.

3. If coupler drawbar does not re-center properly,

you may find excess paint on the coupler mounting

bracket guide wall as shown in Fig.4. This can be

scraped off with an X-acto®knife.

COUPLER OPERATION

TO COUPLE -

Simply push cars together until knuckles bypass

each other and lock into position.

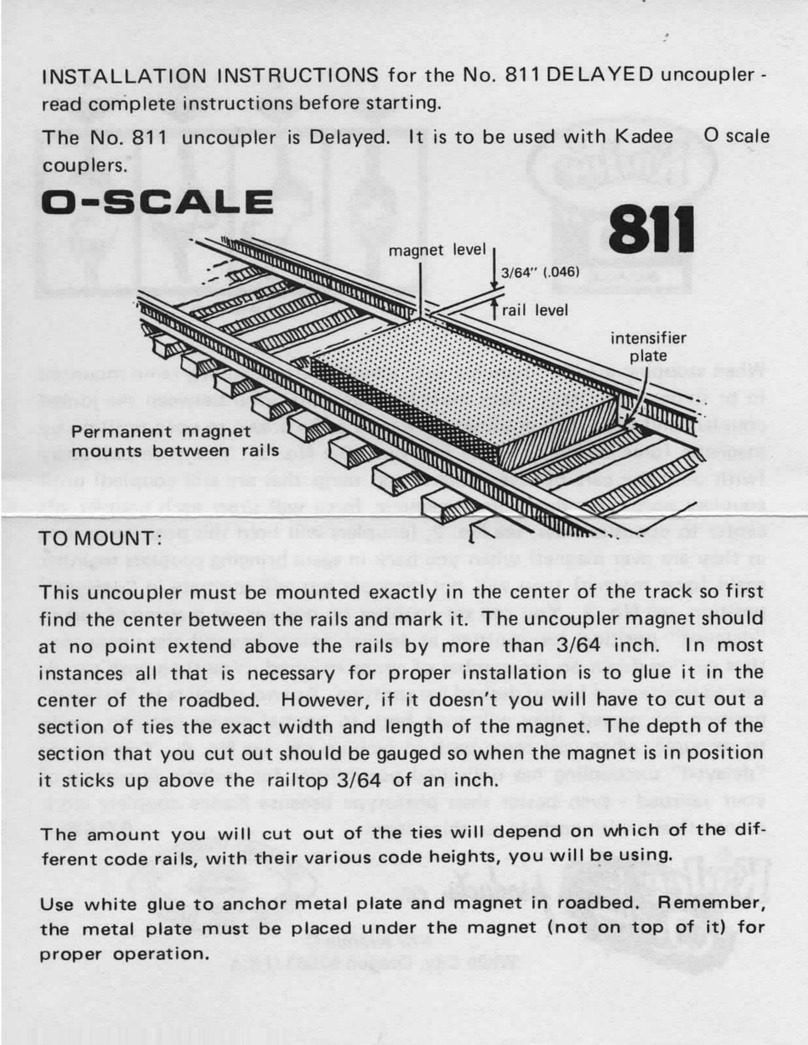

FOR DELAYED UNCOUPLING -

1) Stop with the couplers over an uncoupler and back

up slightly with the couplers still over the uncoupler,

allowing slack to occur between couplers. 2) Pull

forward slightly. Couplers are now in the delayed

position. 3) Back up, pushing the car(s) to the desired

location. Do not permit slack to develop between

couplers. 4) Pull forward, leaving the car(s) where

desired. Couplers automatically return to normal

coupling position.

Use Kadee®Greas-em, the dry lubricant recommended

for use with all Kadee®Magne-Matic® couplers.

Grease-em will not attract the dirt and dust that

gums up the inside of couplers like oil, grease or

other lubricants will. Use our #829 #1-Scale or #880

G-Scale Height Gauge to check for the correct coupler

height and trip pin clearance. The N.M.R.A. standard

for coupler height is the centerline of coupler is 1 1/16”

(1.0625”)for #1-Scale & 1 1/8” (1.125”) G-Scale.

Note: We include extra knuckle springs. The

Replacement Knuckle Spring used on Kadee®

#1-Scale couplers are sold as the #875 (#819-828

couplers) or #1875 (1700 & 1800 series couplers)

Knuckle Spring. The Knuckle Spring used on Kadee®

G-Scale couplers are sold as the #860 Knuckle

Spring.

For Delayed Action Uncoupling use our #842

Uncoupler, #844 Portable Uncoupler, or our #840

Uncoupler mounted in LGB track.

Kadee®coupler conversion list & coupler

conversions are on the Kadee®web site for your

connivance.

www.kadee.com/conv/convpl.htm

©2007 Kadee®Quality Products Co.

081407

Made in the U.S.A.

673 Avenue C

White City, OR 97503

NOTE: If couplers swing open too far when

uncoupling, lower magnet slightly to correct.