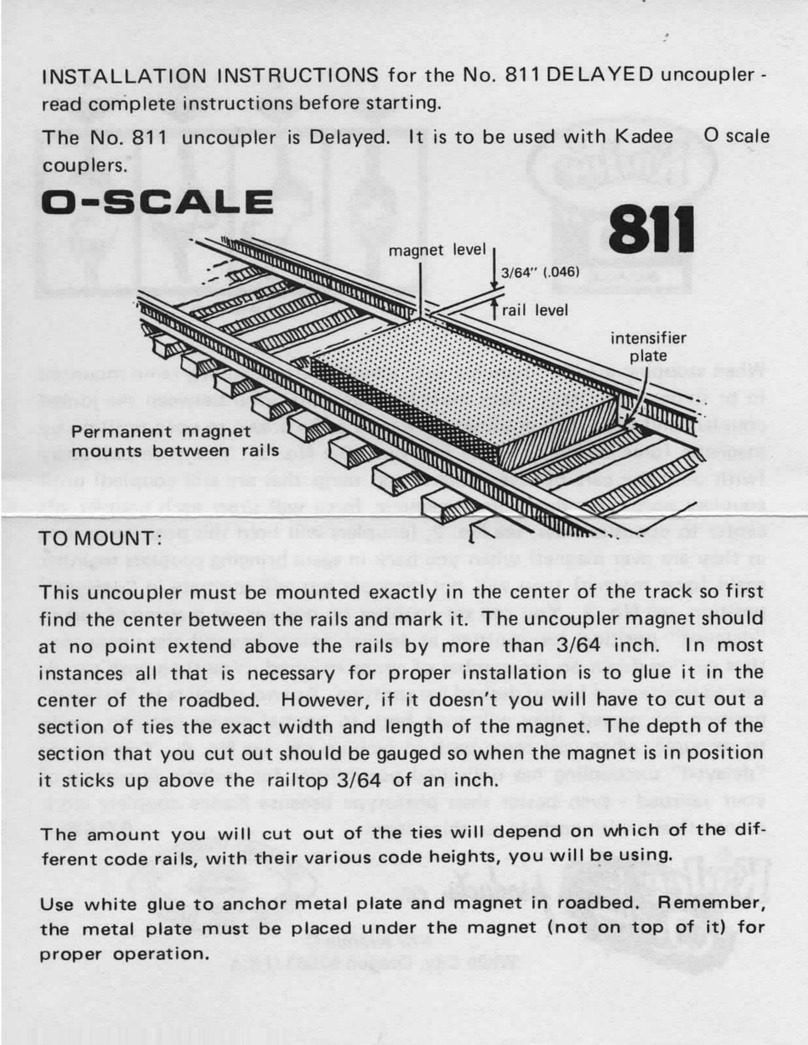

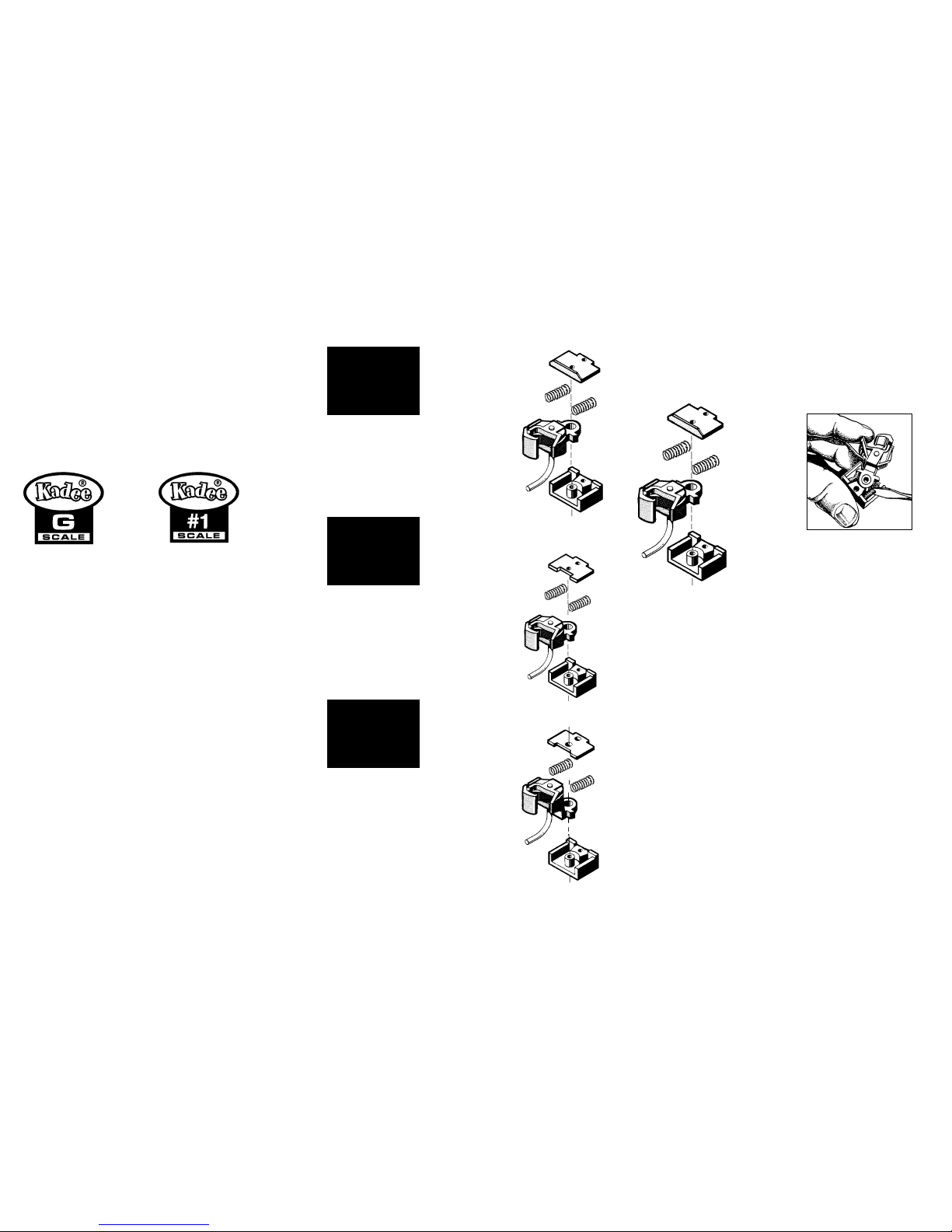

Fig.1

Railtop to underbody

height 1-1/8"

#835

#837

#836

Railtop to underbody

height 1-5/16"

#835

#1835

#1835

#1837

#1836

Centerset Coupler

#836

#1836

Medium Offset Coupler

Railtop to underbody

height 29/32"

#837

#1837

Large Offset Coupler

G-Scale Couplers shown

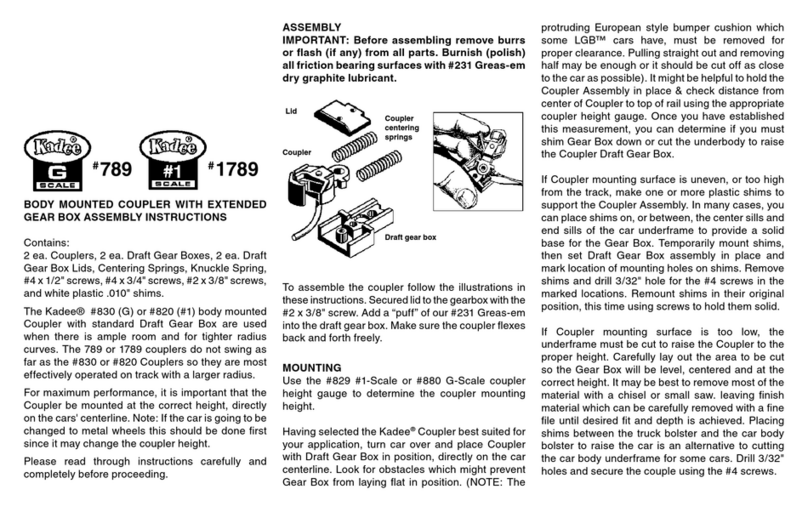

ASSEMBLY

IMPORTANT: Before assembling remove burrs or flash

(if any) from all parts. Burnish (polish) all friction bearing

surfaces with #231 Greas-em dry graphite lubricant.

To assemble the coupler follow the illustrations in these

instructions. The gear box lid is not secured with the screw

until it is mounted. Add a “puff” of our #231 Greas-em into

the draft gear box. Make sure the coupler flexes back and

forth freely.

MOUNTING

Use the #829 #1-Scale or #880 G-Scale coupler height

gauge to determine the coupler mounting height.

G-Scale

#835

A: Railtop to Coupler centerline = 1.125"

B: Railtop to car underbody = 1.310" (1 5/16")

C: Trip Pin clearance = .125" (1/8")

#836

A: Railtop to Coupler centerline = 1.125"

B: Railtop to car underbody = 1.125 (1 1/8")

C: Trip Pin clearance = .125" (1/8")

#837

A: Railtop to Coupler centerline = 1.125"

B: Railtop to car underbody = .900" (29/32")

C: Trip Pin clearance = .125" (1/8")

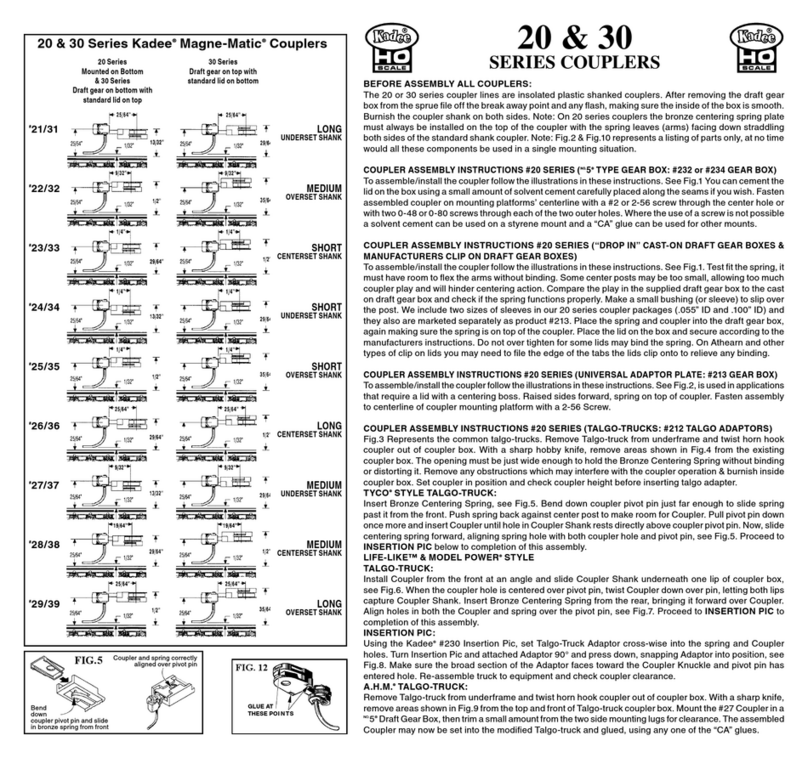

Lid

Coupler

centering

springs

Coupler

Draft gear box

BODY MOUNTED COUPLER WITH SHORTENED

GEAR BOX ASSEMBLY INSTRUCTIONS

2 ea. Couplers, 2 ea. Draft Gear Boxes, 2 ea. Draft

Gear Box Lids, 5 ea. Centering Springs, 1 ea. Knuckle

Spring, 4 ea. 2-56 screws and 4 ea. 2-56 nuts.

Kadee

®

body mounted Couplers with shortened Draft

Gear Boxes are used in special applications where

there is not ample room for the Kadee

®

#830 or #820

body mounted Coupler with standard Draft Gear Box.

The G-scale & #1-scale couplers are available in three

variations as shown in Fig.1

Use the #837 or #1837 Coupler for installation when

the mounting surface is very low and requires using the

coupler having the greatest offset. If alterations to the

car are required, they should be done as carefully and

accurately as possible. For maximum performance, it

is important that the Coupler be mounted at the correct

height, & directly on the cars centerline. #835, #836

& #837 G-scale & #1835, #1836 & #1837 #1-scale

Couplers do not swing as far as the #830 or #820

body mounted Coupler, so they are most effectively

operated on a track with a larger radius.

Please read through instructions carefully and

completely before proceeding.

#1-Scale

#1835

A: Railtop to Coupler centerline = 1.062" (1 1/16")

B: Railtop to car underbody = 1.310" (1 5/16")

C: Trip Pin clearance = .125" (1/8")

#1836

A: Railtop to Coupler centerline = 1.062" (1 1/16")

B: Railtop to car underbody = 1.125 (1 1/8")

C: Trip Pin clearance = .125" (1/8")

#1837

A: Railtop to Coupler centerline = 1.062" (1 1/16")

B: Railtop to car underbody = .900" (29/32")

C: Trip Pin clearance = .125" (1/8")

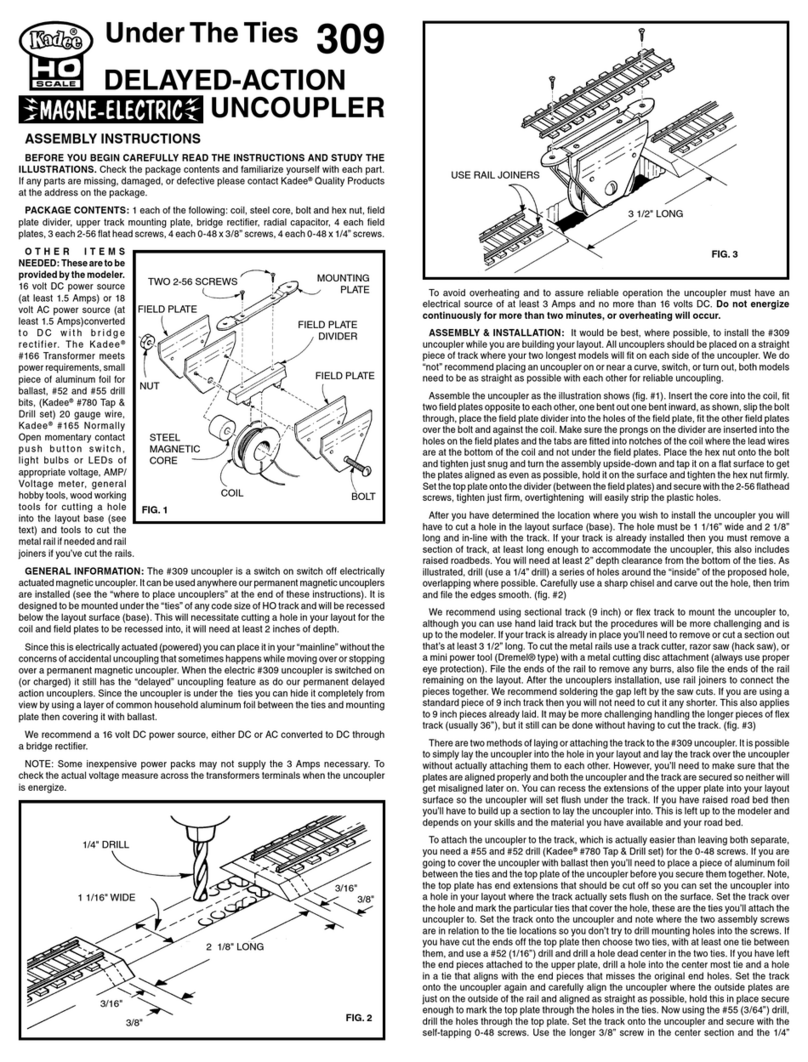

Having selected the Kadee

®

Coupler best suited for your

application, turn car over and place Coupler with Draft

Gear Box in position, directly on the car centerline. Look

for obstacles which might prevent Gear Box from laying flat

in position. (NOTE: The protruding European style bumper

cushion which some LGB™ cars have, must be removed

for proper clearance. Pulling straight out and removing half

may be enough or it should be cut off as close to the car as

possible). It might be helpful to hold the Coupler Assembly

in place & check distance from center of Coupler to top of

rail using the appropriate coupler height gauge. Once you

have established this measurement, you can determine if

you must shim Gear Box down or cut the underbody to raise

the Coupler Draft Gear Box.

If Coupler mounting surface is uneven, or too high from the

track, make one or more plastic shims to support the Coupler

Assembly. In many cases, you can place shims on, or

between, the center sills and end sills of the car underframe

to provide a solid base for the Gear Box. Temporarily mount

shims, then set Draft Gear Box assembly in place and mark

location of mounting holes on shims. Remove shims and drill

and tap for 2-56 screws in the marked locations. Remount

shims in their original position, this time using screws to hold

them solid.

NOTE: When using metal screws in plastic, tapping of the hole is not

required. After drilling a 5/64" hole, the screw will self-tap.

If Coupler mounting surface is too low, the underframe must

be cut to raise the Coupler to the proper height. Carefully

lay out the area to be cut so the Gear Box will be level,

centered and at the correct height. It may be best to remove

most of the material with a chisel or small saw. leaving finish

material which can be carefully removed with a fine file until

desired fit and depth is achieved. Placing shims between

the truck bolster and the car body bolster to raise the car is

an alternative to cutting the car body underframe for some

cars.

The Coupler Assembly can now be screwed into place. An

alternative to tapping the mounting holes is to drill 3/32"

holes through and use 2-56 screws and nuts to secure the

Draft Gear Box. The metal screws can be cut to the required

length with a fine saw. Before cutting, screw on a supplied

nut, so that by removing it after the cutting, the nut will serve

to clean up the thread ends.

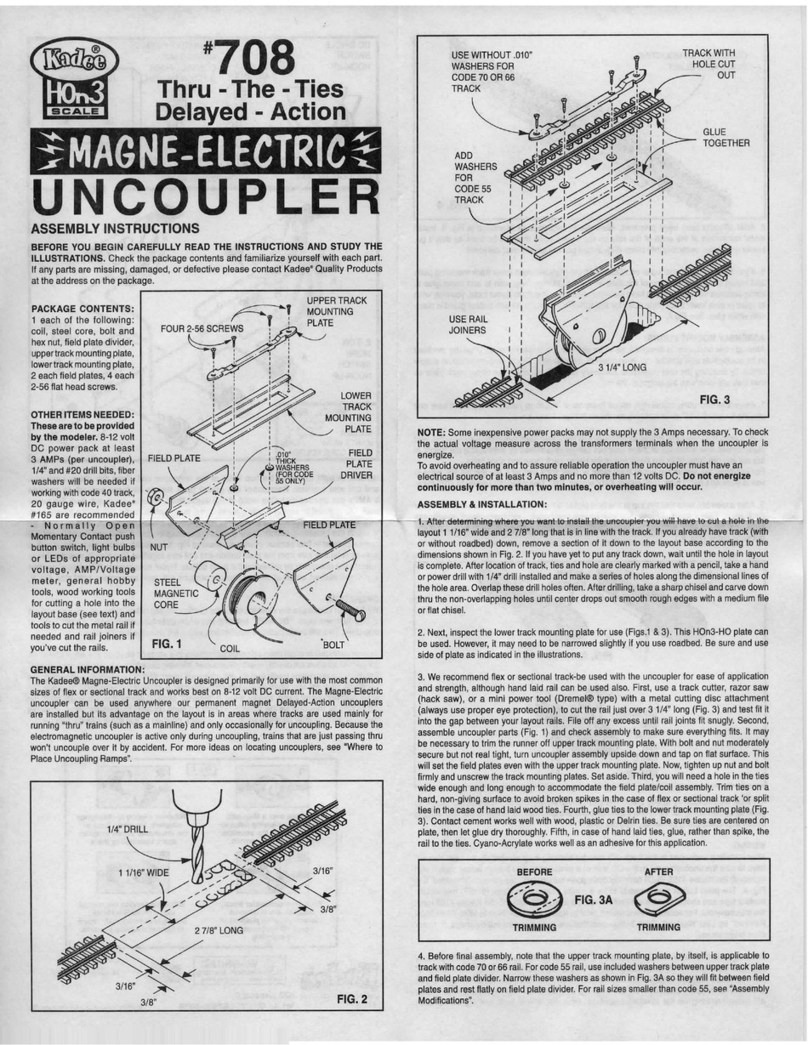

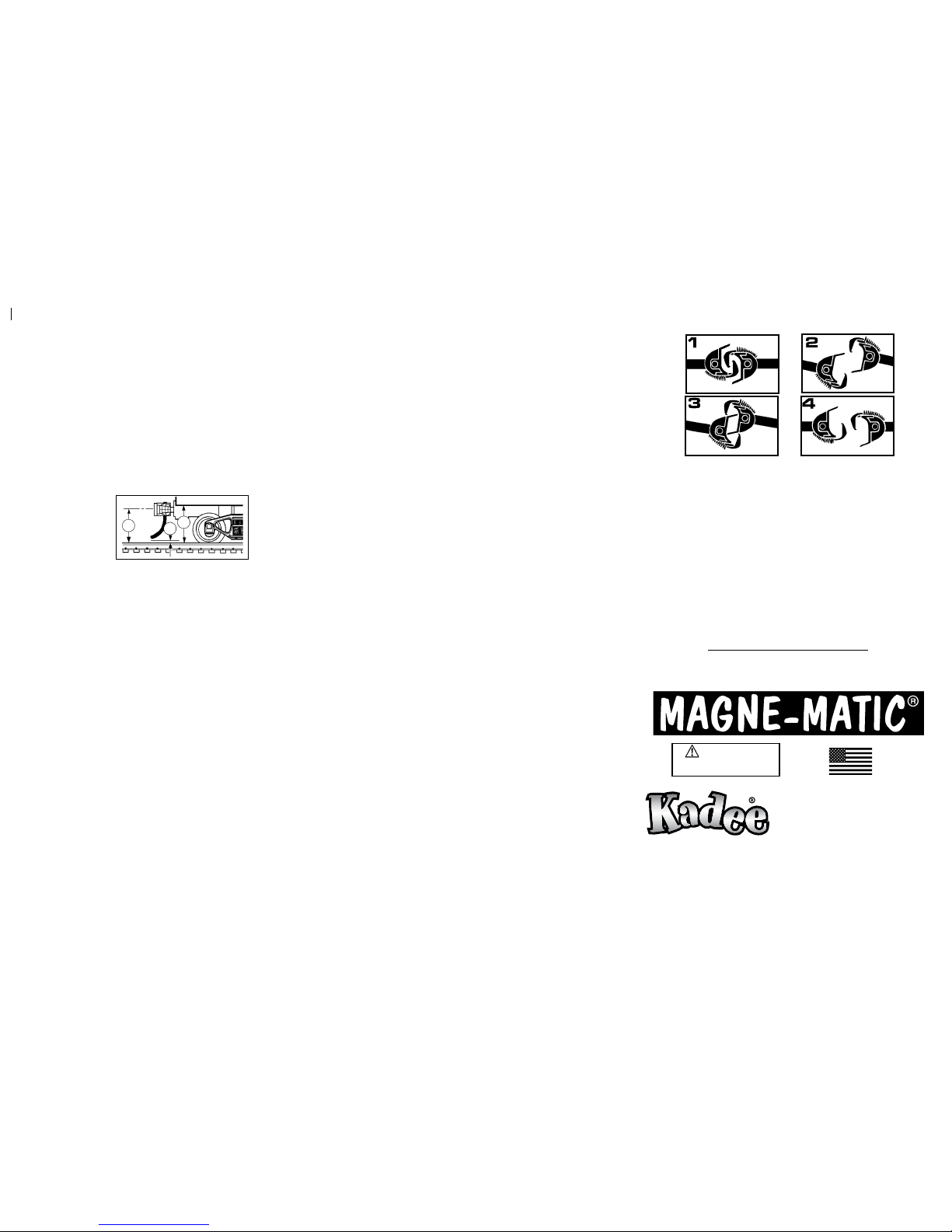

COUPLER OPERATION

TO COUPLE -

Simply push cars together until knuckles bypass each other

and lock into position.

FOR DELAYED UNCOUPLING -

1) Stop with the couplers over an uncoupler and back up

slightly with the couplers still over the uncoupler, allowing

slack to occur between couplers. 2) Pull forward slightly.

Couplers are now in the delayed position. 3) Back up,

pushing the car(s) to the desired location. Do not permit

slack to develop between couplers. 4) Pull forward, leaving

the car(s) where desired. Couplers automatically return to

normal coupling position.

Use Kadee

®

Greas-em, the dry lubricant recommended for

use with all Kadee

®

Magne-Matic

®

couplers. Grease-em will

not attract the dirt and dust that gums up the inside of couplers

like oil, grease or other lubricants will. Use our #829 #1-Scale

or #880 G-Scale Height Gauge to check for the correct coupler

height and trip pin clearance. The N.M.R.A. standard for

coupler height is the centerline of coupler is 1 1/16” (1.0625”)

for #1-Scale & 1 1/8” (1.125”) G-Scale.

NOTE: If couplers swing open too far when

uncoupling, lower magnet slightly to correct.

Note: We include extra knuckle springs. The Replacement

Knuckle Spring used on Kadee

®

#1-Scale couplers are sold as

the #875 (#820-828 couplers) or #1875 (1700 & 1800 series

couplers) Knuckle Spring. The Knuckle Spring used on Kadee

®

G-Scale couplers are sold as the #860 Knuckle Spring.

For Delayed Action Uncoupling use our #842 Uncoupler,

#844 Portable Uncoupler, or our #840 Uncoupler mounted

in LGB track.

Kadee

®

coupler conversion list & coupler conversions are

on the Kadee

®

web site for your connivance.

www.kadee.com/conv/convpl.htm

673 Avenue C,

White City, OR 97503-1078

© 2009, Kadee®Quality Products Co.

012909

Made & Assembled Entirely

in the U.S.A.

Quality Products Co.

WARNING:

CHOKING HAZARD - Small Parts

Not for children under 14 years.

CB

A