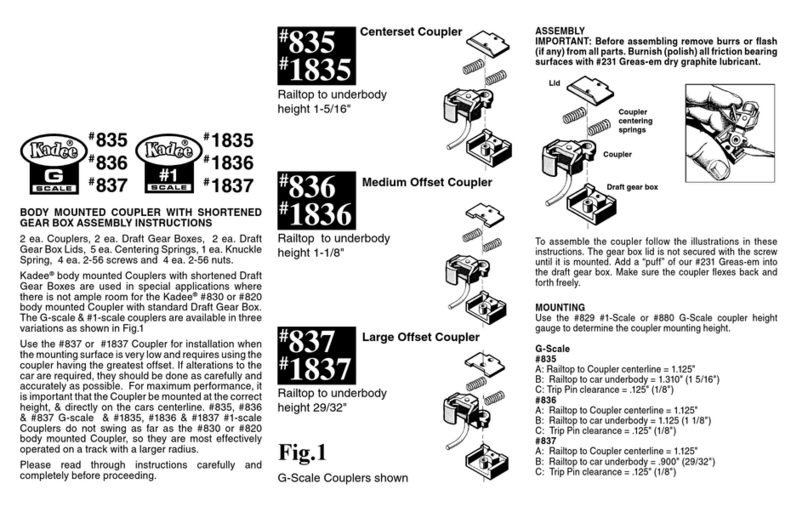

ASSEMBLY INSTRUCTIONS

BEFORE YOU BEGIN CAREFULLY READ THE INSTRUCTIONS AND STUDY THE

ILLUSTRATIONS. Check the package contents and familiarize yourself with each part.

If any parts are missing, damaged, or defective please contact Kadee

®

Quality Products

at the address on the package.

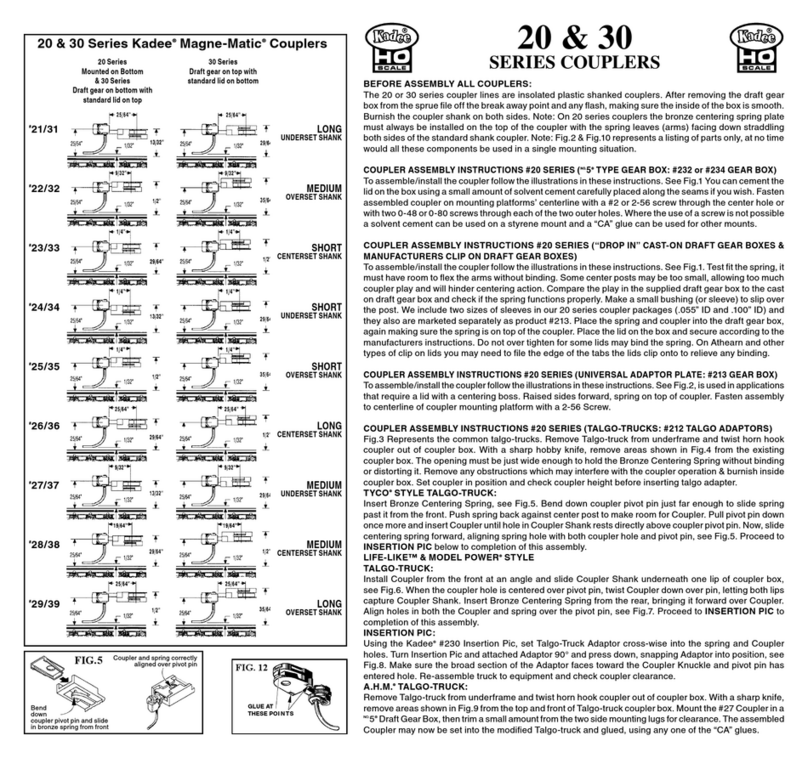

PACKAGE CONTENTS:

1 each of the following: coil, steel core, bolt and hex nut, field

plate divider, upper track mounting plate, bridge rectifier, radial capacitor, 4 each field

plates, 3 each 2-56 flat head screws, 4 each 0-48 x 3/8” screws, 4 each 0-48 x 1/4” screws.

OTHER ITEMS

NEEDED: These are to be

provided by the modeler.

16 volt DC power source

(at least 1.5 Amps) or 18

volt AC power source (at

least 1.5 Amps)converted

to DC with bridge

rectifier. The Kadee

®

#166 Transformer meets

power requirements, small

piece of aluminum foil for

ballast, #52 and #55 drill

bits, (Kadee

®

#780 Tap &

Drill set) 20 gauge wire,

Kadee

®

#165 Normally

Open momentary contact

push button switch,

light bulbs or LEDs of

appropriate voltage, AMP/

Voltage meter, general

hobby tools, wood working

tools for cutting a hole

into the layout base (see

text) and tools to cut the

metal rail if needed and rail

joiners if you’ve cut the rails.

GENERAL INFORMATION: The #309 uncoupler is a switch on switch off electrically

actuated magnetic uncoupler. It can be used anywhere our permanent magnetic uncouplers

are installed (see the “where to place uncouplers” at the end of these instructions). It is

designed to be mounted under the “ties” of any code size of HO track and will be recessed

below the layout surface (base). This will necessitate cutting a hole in your layout for the

coil and field plates to be recessed into, it will need at least 2 inches of depth.

Since this is electrically actuated (powered) you can place it in your “mainline” without the

concerns of accidental uncoupling that sometimes happens while moving over or stopping

over a permanent magnetic uncoupler. When the electric #309 uncoupler is switched on

(or charged) it still has the “delayed” uncoupling feature as do our permanent delayed

action uncouplers. Since the uncoupler is under the ties you can hide it completely from

view by using a layer of common household aluminum foil between the ties and mounting

plate then covering it with ballast.

We recommend a 16 volt DC power source, either DC or AC converted to DC through

a

bridge rectifier

.

NOTE: Some inexpensive power packs may not supply the 3 Amps necessary. To

check the actual voltage measure across the transformers terminals when the uncoupler

is energize.

To avoid overheating and to assure reliable operation the uncoupler must have an

electrical source of at least 3 Amps and no more than 16 volts DC. Do not energize

continuously for more than two minutes, or overheating will occur.

ASSEMBLY & INSTALLATION: It would be best, where possible, to install the #309

uncoupler while you are building your layout. All uncouplers should be placed on a straight

piece of track where your two longest models will fit on each side of the uncoupler. We do

“not” recommend placing an uncoupler on or near a curve, switch, or turn out, both models

need to be as straight as possible with each other for reliable uncoupling.

Assemble the uncoupler as the illustration shows (fig. #1). Insert the core into the coil, fit

two field plates opposite to each other, one bent out one bent inward, as shown, slip the bolt

through, place the field plate divider into the holes of the field plate, fit the other field plates

over the bolt and against the coil. Make sure the prongs on the divider are inserted into the

holes on the field plates and the tabs are fitted into notches of the coil where the lead wires

are at the bottom of the coil and not under the field plates. Place the hex nut onto the bolt

and tighten just snug and turn the assembly upside-down and tap it on a flat surface to get

the plates aligned as even as possible, hold it on the surface and tighten the hex nut firmly.

Set the top plate onto the divider (between the field plates) and secure with the 2-56 flathead

screws, tighten just firm, overtightening will easily strip the plastic holes.

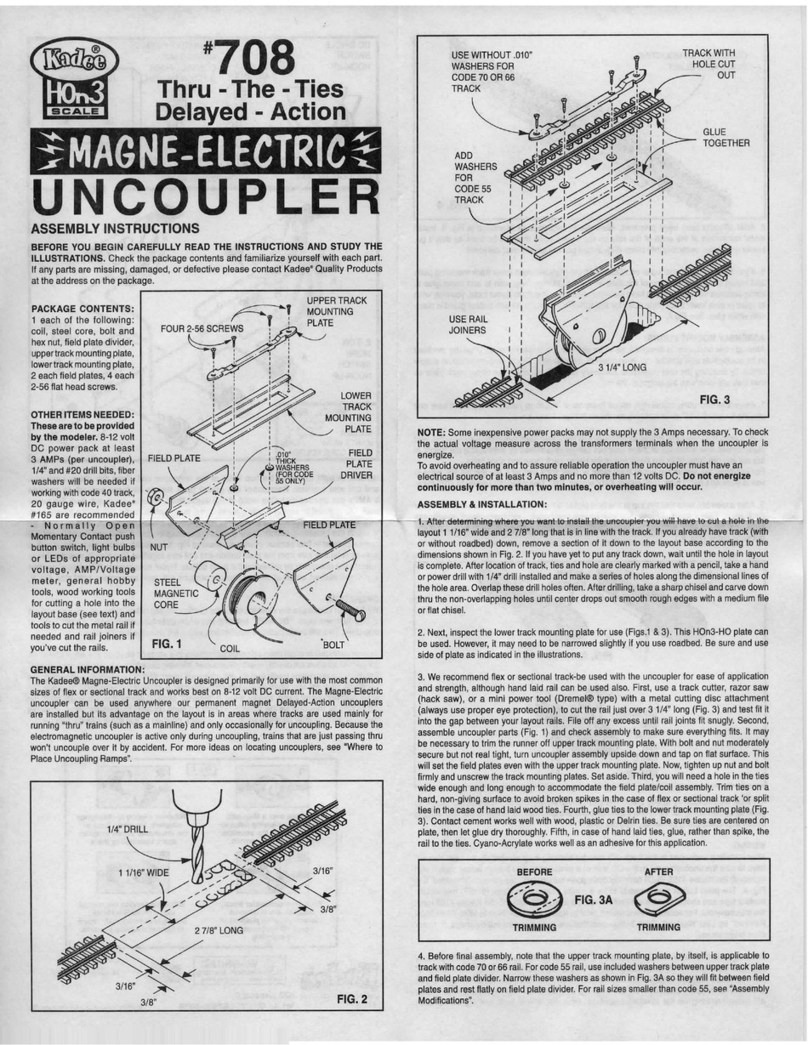

After you have determined the location where you wish to install the uncoupler you will

have to cut a hole in the layout surface (base). The hole must be 1 1/16” wide and 2 1/8”

long and in-line with the track. If your track is already installed then you must remove a

section of track, at least long enough to accommodate the uncoupler, this also includes

raised roadbeds. You will need at least 2” depth clearance from the bottom of the ties. As

illustrated, drill (use a 1/4” drill) a series of holes around the “inside” of the proposed hole,

overlapping where possible. Carefully use a sharp chisel and carve out the hole, then trim

and file the edges smooth. (fig. #2)

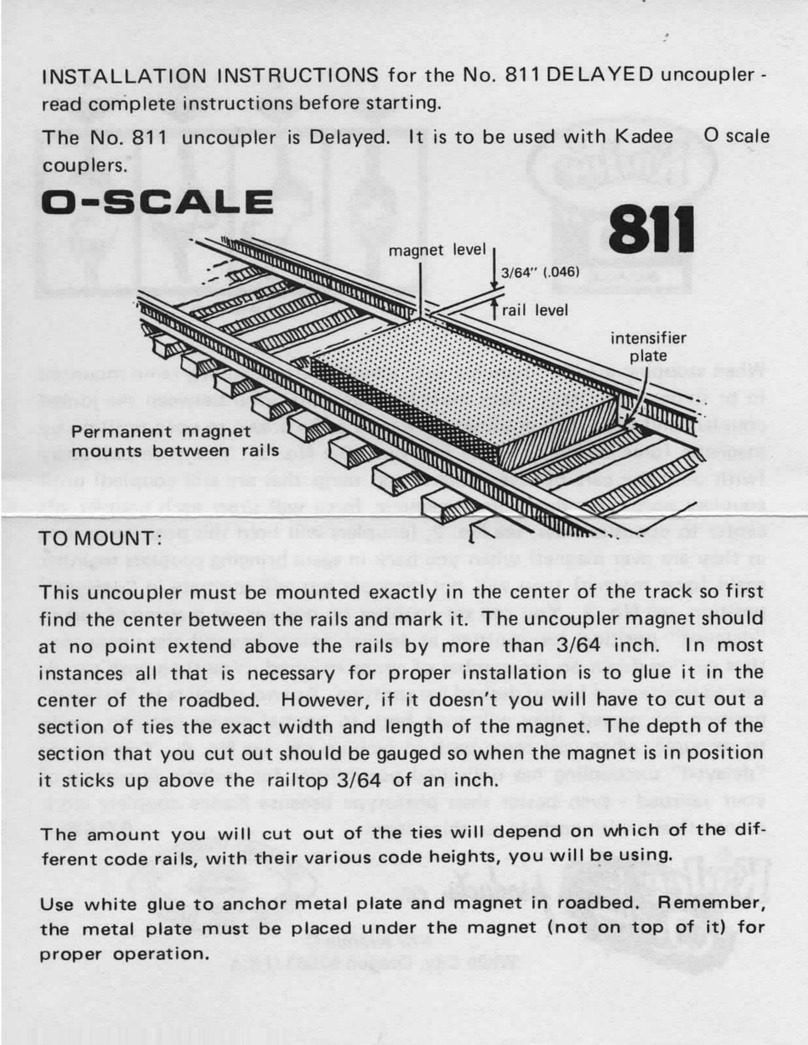

We recommend using sectional track (9 inch) or flex track to mount the uncoupler to,

although you can use hand laid track but the procedures will be more challenging and is

up to the modeler. If your track is already in place you’ll need to remove or cut a section out

that’s at least 3 1/2” long. To cut the metal rails use a track cutter, razor saw (hack saw), or

a mini power tool (Dremel® type) with a metal cutting disc attachment (always use proper

eye protection). File the ends of the rail to remove any burrs, also file the ends of the rail

remaining on the layout. After the uncouplers installation, use rail joiners to connect the

pieces together. We recommend soldering the gap left by the saw cuts. If you are using a

standard piece of 9 inch track then you will not need to cut it any shorter. This also applies

to 9 inch pieces already laid. It may be more challenging handling the longer pieces of flex

track (usually 36”), but it still can be done without having to cut the track. (fig. #3)

There are two methods of laying or attaching the track to the #309 uncoupler. It is possible

to simply lay the uncoupler into the hole in your layout and lay the track over the uncoupler

without actually attaching them to each other. However, you’ll need to make sure that the

plates are aligned properly and both the uncoupler and the track are secured so neither will

get misaligned later on. You can recess the extensions of the upper plate into your layout

surface so the uncoupler will set flush under the track. If you have raised road bed then

you’ll have to build up a section to lay the uncoupler into. This is left up to the modeler and

depends on your skills and the material you have available and your road bed.

To attach the uncoupler to the track, which is actually easier than leaving both separate,

you need a #55 and #52 drill (Kadee

®

#780 Tap & Drill set) for the 0-48 screws. If you are

going to cover the uncoupler with ballast then you’ll need to place a piece of aluminum foil

between the ties and the top plate of the uncoupler before you secure them together. Note,

the top plate has end extensions that should be cut off so you can set the uncoupler into

a hole in your layout where the track actually sets flush on the surface. Set the track over

the hole and mark the particular ties that cover the hole, these are the ties you’ll attach the

uncoupler to. Set the track onto the uncoupler and note where the two assembly screws

are in relation to the tie locations so you don’t try to drill mounting holes into the screws. If

you have cut the ends off the top plate then choose two ties, with at least one tie between

them, and use a #52 (1/16”) drill and drill a hole dead center in the two ties. If you have left

the end pieces attached to the upper plate, drill a hole into the center most tie and a hole

in a tie that aligns with the end pieces that misses the original end holes. Set the track

onto the uncoupler again and carefully align the uncoupler where the outside plates are

just on the outside of the rail and aligned as straight as possible, hold this in place secure

enough to mark the top plate through the holes in the ties. Now using the #55 (3/64”) drill,

drill the holes through the top plate. Set the track onto the uncoupler and secure with the

self-tapping 0-48 screws. Use the longer 3/8” screw in the center section and the 1/4”

Under The Ties

DELAYED-ACTION

UNCOUPLER

309

TWO 2-56 SCREWS MOUNTING

PLATE

FIELD PLATE

NUT

STEEL

MAGNETIC

CORE

COIL BOLT

FIELD PLATE

DIVIDER

FIELD PLATE

FIG. 1

1/4" DRILL

1 1/16" WIDE

2 1/8" LONG

3/16"

3/8"

3/16"

3/8"

FIG. 2

USE RAIL JOINERS

3 1/2" LONG

FIG. 3