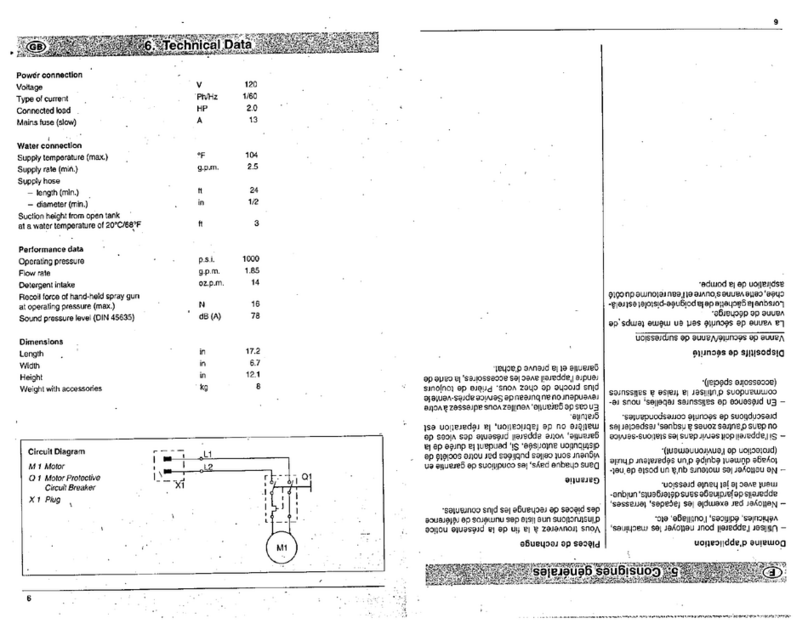

Page 6/11

International Service Information

International Service Information

Dec. 22nd,1999

HD 1050 DE Cage

New Unit Information

1. Servopress handgun is open.

When the servopress handgun is completely

open, water flows from the pressure chamber (7)

through the non-return valve (6) and through both

injectors (2+4) to the high-pressure outlet (1).

The ball (9) is pressed against the valve seat by

the pump pressure, thus sealing the connection

bore (12) to the suction chamber (11).

The pressure gauge (5) indicates the operating

pressure.

The pressure in the connection bore (17) is

approx. 30 bar less due to the injector influence

(4) (control pressure).

The motor runs with operating speed when the

handgun is open.

2. Servopress handgun is partly closed.

When the handgun is partly closed, the pressure

in the pressure chamber (7) does not increase.

Due to the decreased water flow rate, the

influence of the injector (4) is reduced so that the

control pressure in the connection bore (17)

increases. The increasing control pressure

pushes the overflow valve spindle (16) against

the spring (14) and slightly to the right. The tip of

the spindle pushes the ball (9) off its seat so that

part of the water can flow through the connection

bores (8) and (12) to the suction chamber (11).

3. Servopress handgun is completely

closed.

When the handgun is completely closed, the

pressure in the pressure chamber (7) increases.

The increased control pressure pushes the

overflow valve spindle (16) via connection bore

(17) completely to the right. The tip of the spindle

pushes the ball (9) off its seat, so that the entire

water volume can flow through the connection

bores (8) and (12) to the suction chamber.

As soon as the handgun is closed, the non-return

valve closes (6). Therefore the entire pressure

in the system between handgun and non-return

valve (6) is trapped.

The pump continues running with decreased

pressure in circulation operation.

The motor continues running via automatic r.p.m.

control with decreased circulation r.p.m.

4. Servopress handgun is opened.

When the handgun is opened, the pressure in

the system decreases.

The overflow valve spindle (16) is pushed back

by the spring (14) to its original position to the

left. The spring (10) and the pump pressure of

the connection bore (8) push the ball (9) back

onto the valve seat.

The connection bore (8) is thereby closed and

the operating pressure can be built up again.

The engine r.p.m. increases to the operating

speed.

Unit function: overflow valve