V2.01

25360_EDEBDA0280-2320-1_EN

3

6 Commissioning the System.....................................................................................................20

6.1 General notes on commissioning..........................................................................................20

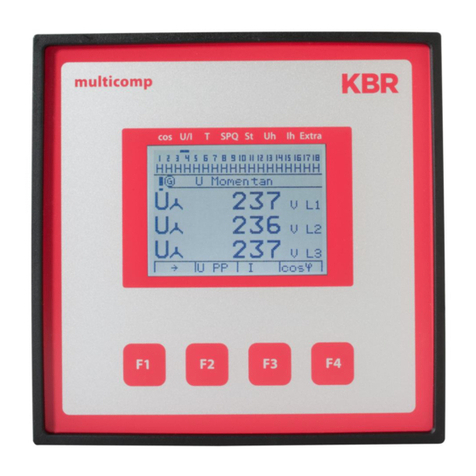

7 Navigation and Device Displays.............................................................................................22

8 Device displays of the main menus ......................................................................................24

9 Description of the individual display windows ................................................................26

9.1. Initialization window:.................................................................................................................26

9.2 Commissioning window if no stage power is programmed........................................26

9.3 Start menu window....................................................................................................................29

9.4 Stage state window:...................................................................................................................31

9.5 Service window:...........................................................................................................................32

9.6 Commissioning window:..........................................................................................................33

9.7 Switching performance window: ..........................................................................................35

10 Notes on Troubleshooting........................................................................................................42

11 System and Safety

Device Maintenance...................................................................................................................43

12 Technical Data...............................................................................................................................44

12.1 Measuring and display values.................................................................................................44

12.2 Measuring accuracy....................................................................................................................45

12.3 Measuring principle....................................................................................................................45

12.4 Device memory............................................................................................................................45

12.5 Limits:...............................................................................................................................................45

12.6 Power supply.................................................................................................................................45

12.7 Hardware inputs and outputs.................................................................................................46

12.7.1 Hardware inputs...........................................................................................................................46

12.7.2 Hardware outputs ......................................................................................................................46

12.8 Electrical connection..................................................................................................................47

12 Selection of cables and fuses ..................................................................................................49

14 Data point description for the Modbus protocol.............................................................50

14.1 Modbus commands supported..............................................................................................51

14.2 Data formats..................................................................................................................................51

14.3 Interface parameters..................................................................................................................54

14.4 Device settings.............................................................................................................................54

14.5 Data points.....................................................................................................................................60

15 Device information .....................................................................................................................63

Table of contents