Rev. 1.00 3

22586_EDEBDA0253-0318-1_EN

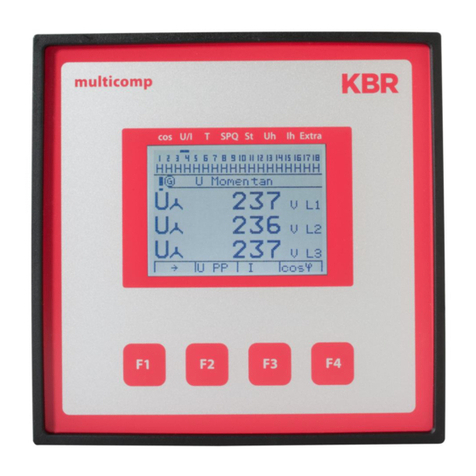

KBR multicomp F144-3 6DO/6ROTable of contents

1 Functional principle

of the controller...................................8

2 Control and display panel............. 11

3 Setting range of the

congurable parameters:.............. 14

4 Installation and electrical connec-

tion of the system ............................ 16

4.1 General, very important

information......................................... 16

4.2 Current transformer connection

and measuring voltage.................. 17

4.3 Current transformer dimensions 17

4.4 Standard connection diagrams .. 17

5 Commissioning the system.......... 20

5.1 General notes on commissioning20

6 Navigation and device displays .. 22

7 Device displays of the

main menus ....................................... 24

8 Description of the individual

display windows............................... 26

8.1 Initialization window: ..................... 26

8.2

Commissioning window if no

stage power is programmed ..........26

8.3 Start menu window:........................ 30

8.4 Stage state window:........................ 31

8.5 Service window: ............................... 32

8.6 Commissioning window:............... 33

8.7 Switching performance

window:............................................... 36

8.8 Error message window: ................. 38

8.9 Extras window................................... 39

9 Notes on troubleshooting ............ 42

10 System and safety

device maintenance........................ 43

11 Technical data.................................... 44

11.1 Measuring and display values..... 44

11.2 Measuring accuracy ........................ 45

11.3 Measuring principle ........................ 45

11.4 Device memory................................. 45

11.5 Other limits:........................................ 45

11.6 Power supply ..................................... 45

11.7 Hardware inputs and outputs ..... 46

11.7.1 Hardware inputs............................... 46

11.7.2 Hardware outputs ........................... 46

11.8 Electrical connection ...................... 47

11.9 Mechanical data ............................... 48

11.10 Standards and miscellaneous...... 48

12 Selection of cables and fuses....... 49

13 Data point description

for the Modbus protocol ............... 50

multicomp F144-3 ........................... 50

13.1 Modbus

commands supported.................... 51

13.2 Data formats ...................................... 51

13.3 Interface parameters....................... 54

13.4 Device settings.................................. 54

13.5 Data points......................................... 60

13.6 Device information.......................... 63