Table of Contents

ma_dr_s6-cu-k-inst-20087885_en iii

Table of Contents

1 Introduction ................................................................................................................................................... 7

1.1 Markings................................................................................................................................................ 7

1.1.1 Warnings................................................................................................................................. 7

1.1.2 Information notes .................................................................................................................... 7

1.1.3 Symbols and markers ............................................................................................................. 8

1.2 Laws and guidelines.............................................................................................................................. 8

1.3 Warranty and liability............................................................................................................................. 8

1.4 Support.................................................................................................................................................. 8

1.5 Copyright............................................................................................................................................... 8

2 General Safety Instructions.......................................................................................................................... 10

3 Product description ...................................................................................................................................... 11

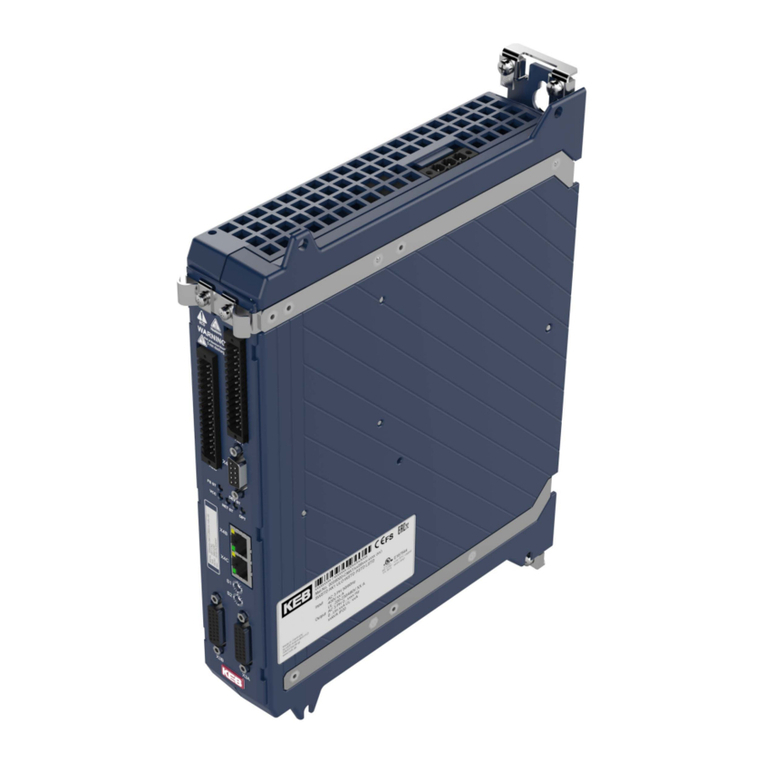

3.1 Description of the control board COMPACT ......................................................................................... 11

3.2 Variants of the control board Pro .......................................................................................................... 11

3.3 Safety functions..................................................................................................................................... 11

3.4 Accessories........................................................................................................................................... 12

3.5 Connection and control elements.......................................................................................................... 13

3.6 Motor monitoring X1C (temperature, brake) ......................................................................................... 13

3.7 Control terminal strip X2A ..................................................................................................................... 14

3.8 Safety terminal block X2B..................................................................................................................... 14

3.9 CAN bus and analog inputs and outputs X2C....................................................................................... 14

3.10 Encoder interfaces X3A, X3B................................................................................................................ 14

3.11 Diagnostic interface X4A....................................................................................................................... 14

3.12 Fieldbus interfaces X4B, X4C ............................................................................................................... 14

3.13 Status LEDs .......................................................................................................................................... 14

3.13.1 Boot display ............................................................................................................................ 14

3.13.2 VCC - LED .............................................................................................................................. 15

3.13.3 NET ST - LED......................................................................................................................... 15

3.13.4 DEV ST - LED......................................................................................................................... 15

3.13.5 OPT - LED .............................................................................................................................. 15

4 Connection of the control............................................................................................................................. 16

4.1 Assembly of wires ................................................................................................................................. 16

4.2 Terminal strip X2A................................................................................................................................. 17

4.2.1 Digital Inputs ........................................................................................................................... 17

4.2.2 Digital Outputs ........................................................................................................................ 18

4.2.3 Relay output;........................................................................................................................... 18

4.2.4 Voltage supply ........................................................................................................................ 19

4.3 Terminal block X2B............................................................................................................................... 19

4.3.1 Inputs STO.............................................................................................................................. 19

4.3.2 Digital outputs ......................................................................................................................... 20

4.3.3 Voltage input........................................................................................................................... 20

4.4 Terminal block X2C............................................................................................................................... 21

4.4.1 Analog input............................................................................................................................ 22

4.4.2 Analog output.......................................................................................................................... 22

5 Diagnosis/visualisation X4A ........................................................................................................................ 24

5.1 Assignment of the terminal strip X4A.................................................................................................... 24