KEENCUT ARTIST User manual

Other KEENCUT Cutter manuals

KEENCUT

KEENCUT EXCALIBUR 1000X User manual

KEENCUT

KEENCUT Excalibur 6000 User manual

KEENCUT

KEENCUT ARTIST plus User manual

KEENCUT

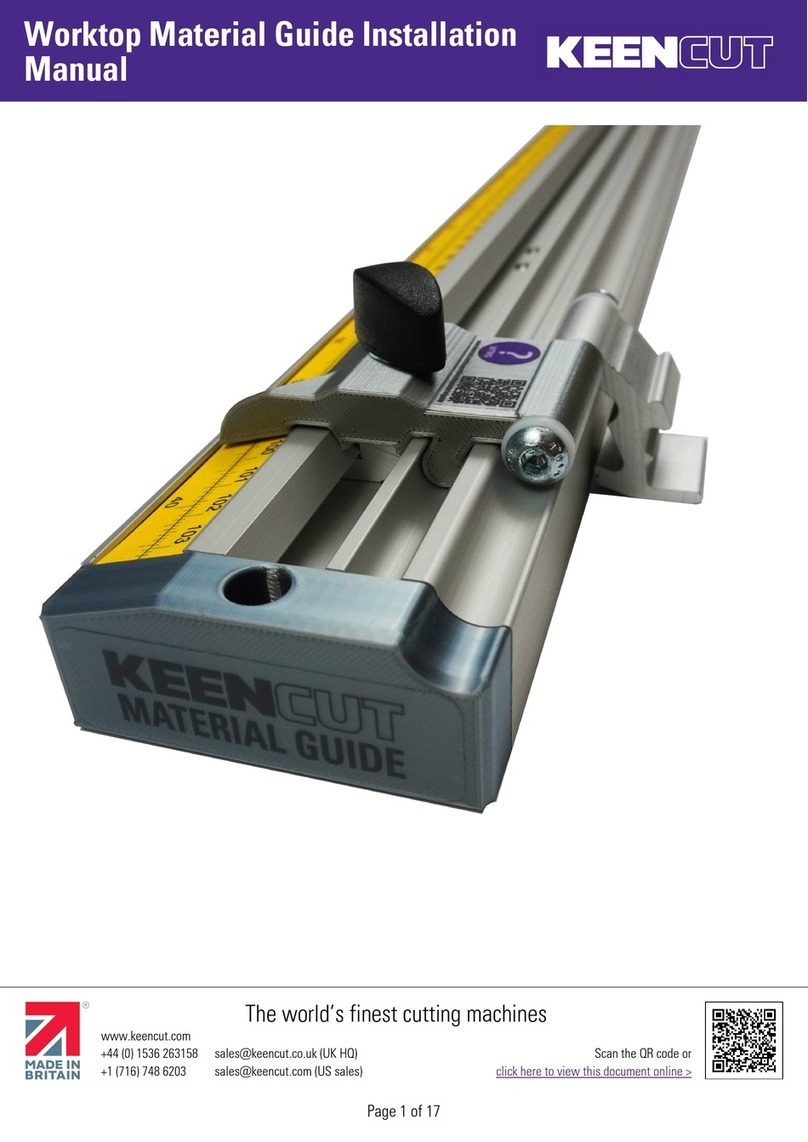

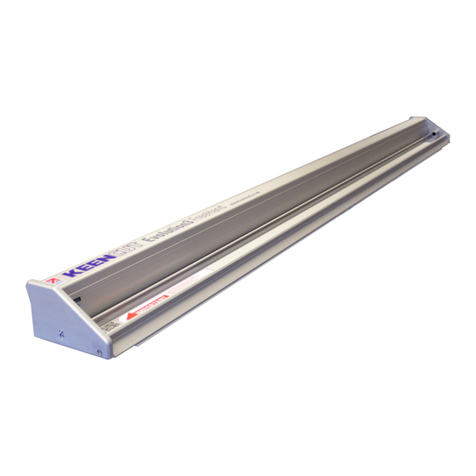

KEENCUT Material Guide User manual

KEENCUT

KEENCUT Sabre 2 Series User manual

KEENCUT

KEENCUT Evolution E2 User manual

KEENCUT

KEENCUT Evolution3 FreeHand User manual

KEENCUT

KEENCUT Evolution3 SmartFold User manual

KEENCUT

KEENCUT Evolution3 SmartFold User manual

KEENCUT

KEENCUT Evolution3 SmartFold User manual

KEENCUT

KEENCUT EXCALIBUR 3S User manual

KEENCUT

KEENCUT Evolution3 BenchTop User manual

KEENCUT

KEENCUT SteelTrak 165 User manual

KEENCUT

KEENCUT Javelin User manual

KEENCUT

KEENCUT SteelTrak 165 User manual

KEENCUT

KEENCUT Evolution3 BenchTop User manual

KEENCUT

KEENCUT Evolution 3 SmartFold Maintenance manual

KEENCUT

KEENCUT Evolution Bench User manual

KEENCUT

KEENCUT SteelTrak User manual

KEENCUT

KEENCUT Excalibur 6000 User manual

Popular Cutter manuals by other brands

Milwaukee

Milwaukee HEAVY DUTY M12 FCOT Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual