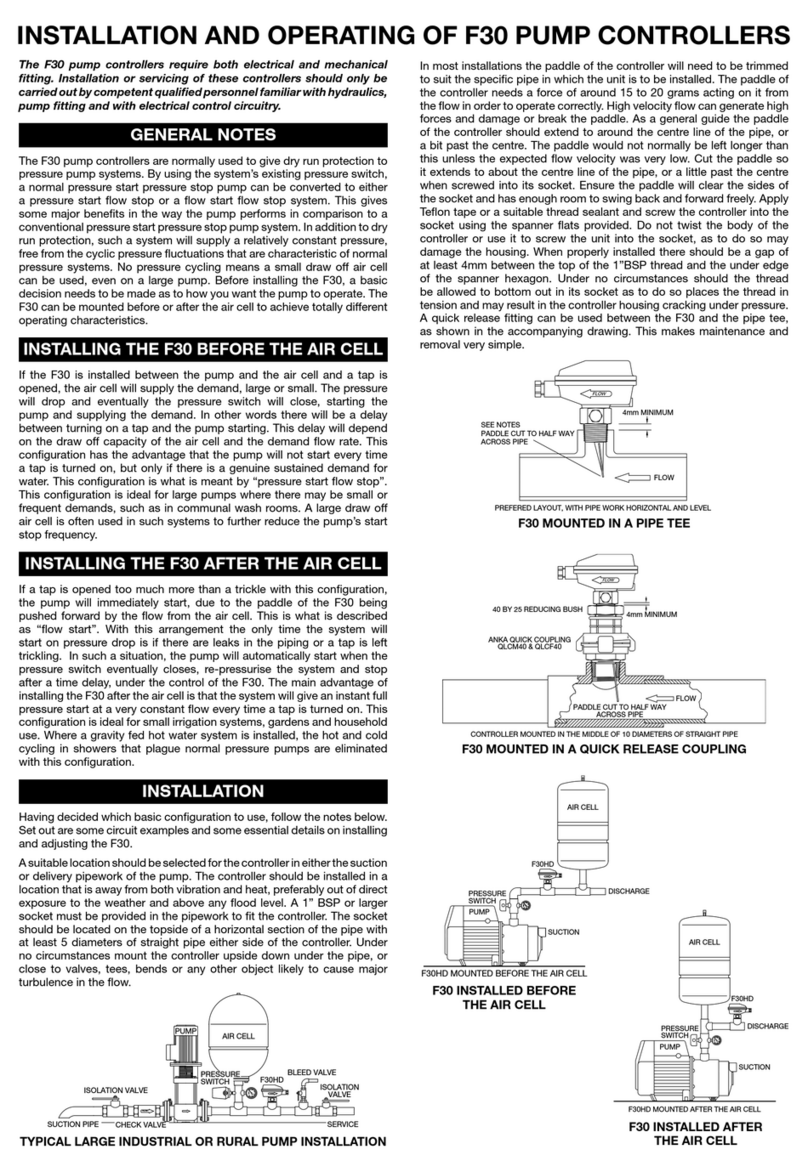

INSTALLATION

The PG20 is suitable for use in all cold-water based

applications such as potable water, seawater, bore

water, chlorinated pool water, brackish water or effluent.

A suitable location should be selected for the switch in

the delivery pipework of the pump. The switch should be

installed in a location that is away from both vibration and

heat, preferably out of direct exposure to the weather and

above any flood level. Drill and tap a 1/4” BSP thread in

the pipework at the required location and fit the PG20

Pressure Guard using a 1/4” brass or stainless nipple (not

supplied). The PG20 can be mounted in any orientation

required in either vertical or horizontal pipework.

Apply a suitable thread sealant tape or thread paste

and screw the PG20 and its interposing nipple into the

pipework using the spanner flats provided. When properly

installed the controller should be square to the axis of the

pipe with the controls in an accessible position.

ELECTRICAL

IMPORTANT

The PG20 Pressure Guard is available in a number of

configurations. Options include various supply voltages

and output contacts that may be normally open or

normally closed. The PG20 is also available with a built

in high capacity output drive system for the direct control

of large single phase pump motors. Check the model

number before installing this device to ensure you are

installing the correct model for the specific application.

The PG20 Pressure Guard requires a stable supply

voltage in order to operate correctly. Pay particular

attention to cable sizes and ensure cables are adequate

for the specific load. This is particularly important where

long cable runs are to be used in the installation. If the

voltage drop associated with the starting of the pump

motor is excessive the PG20 will automatically reset and

this may cause the pump to jog. Jogging can snap the

main spindle of a pump very easily, so please take all

precautions to ensure the voltage supply to the PG20 is

stable and that the current carrying capacity of the cable

is adequate for the job. For mains voltage applications we

recommend that the supply to the PG20 be isolated by a

10Amp RCD that has a maximum trip current of 30mA.

WARNING

When installing the PG20 the socket outlet

connection (GPO) for the input power must be

accessible and must be positioned in a dry and

protected location out of the weather and above

any flood or water level. Where the PG20 is to be

used to control pump motors up to 2.4kW 3HP

the supply to the PG20 must be protected by a

10 Amp fuse or by a 10 Amp circuit breaker.

FIXED INSTALLATION

WARNING

Mains voltage fixed installations must only ever

be carried out by a licensed electrician and must

conform to local wiring rules.

BROWNOUT OR BLACKOUT

If a blackout or brownout occurs while the PG20 is

operating, the pressure switch will not retain any memory

of its previous state. It will simply shut down the system.

When power resumes the PG20 will reboot, restart

the system and run the preset start-up time from the

beginning. A manual reboot can be done at any time by

simply pressing the reset button on the top deck of the

switch.

ADJUSTING SETTINGS

There are 4 rotary switches located under the clear cover

on the top deck of the PG20. These 4 dials are for adjusting

the settings that control the PG20’s actions. To access

the 4 dials undo the 2 screws that hold the clear cover in

place. Note that the clear cover must always be replaced

and tightened after making changes to the settings. Any

changes to the settings will not take effect until the reset

button is pressed or the supply is reset.

WARNING

Without the cover in place the PG20 is not water

resistant and presents a potential shock hazard.

Take great care not to splash water onto the

PG20 when the control cover is removed and

always replace the cover immediately and fully

tighten its securing screws after any changes to

the settings are made.

After you make any change to the settings on the 4

control dials you must always press the reset button

for the changes to take effect.