INSTALLING AND OPERATING THE KELCO F21 SERIES FLOW SWITCH

INTRODUCTION

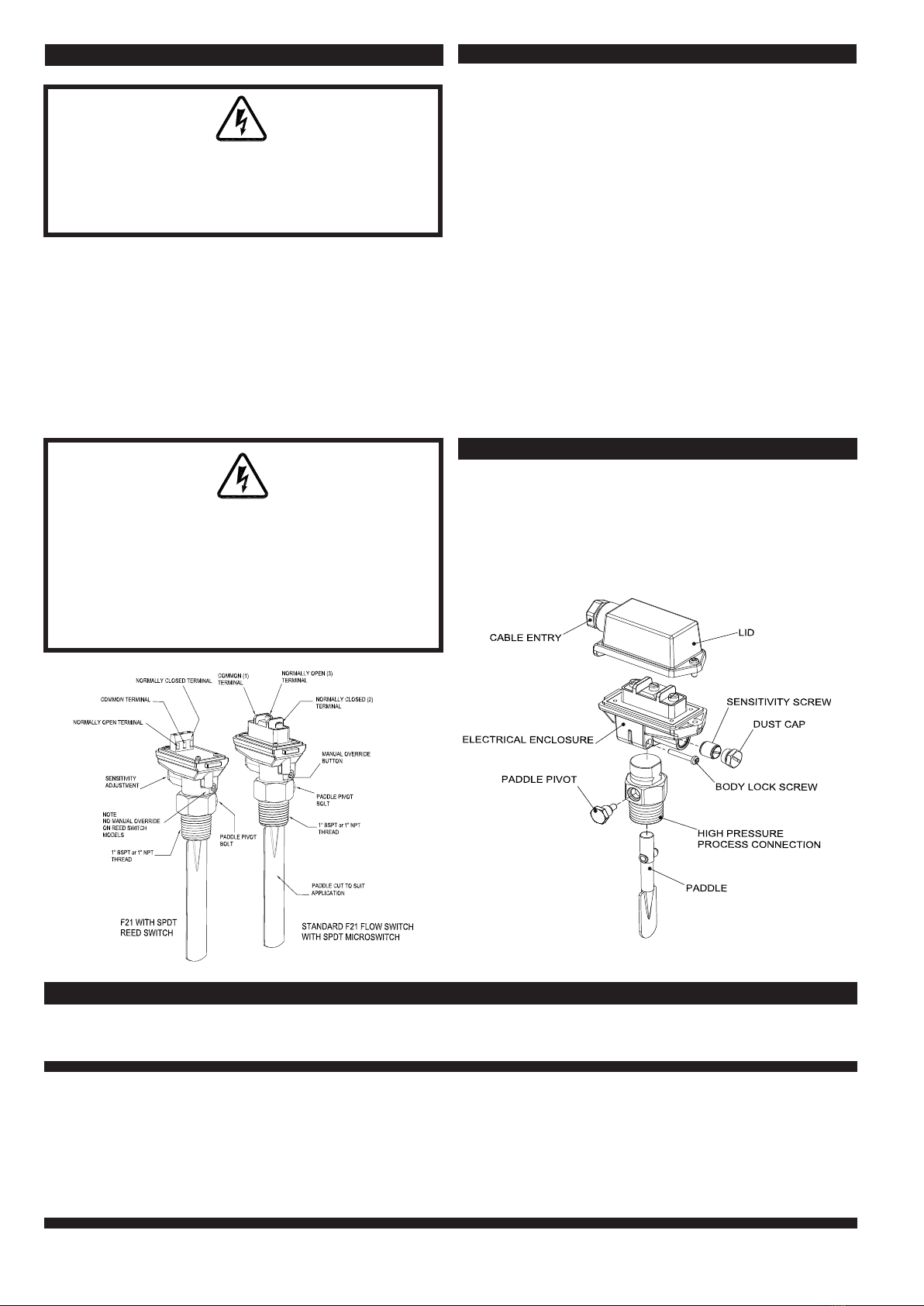

This F21 ow switch may have been supplied in one of several available congurations. The model number of the specic switch is located inside the lid of the electrical housing. The

F21 series ow switch is a versatile heavy-duty paddle ow switch suitable for detecting ow of liquids in pipes of any diameter from 25 mm (1”) upward. This ow switch has several

unique features: A) The complete electrical assembly can be removed from the switch by undoing and removing the locking screw in the split clamp on the side of the switch’s electrical

housing. With the locking screw removed, the electrical housing can be pulled straight off the wet end of the switch. Removing the electrical housing allows the wet end of the switch

to be unscrewed from pipework without disturbing the cable connection to the switch. This means the paddle of the switch can be changed, inspected or trimmed without the need to

disturb the electrical connection to the switch. replace and tighten the locking screw after completing any work on the wet end of the switch. B) The standard version of the F21 ow

switch has a built-in manual override. On the end of the switch body underneath the cable entry port is a spring loaded push button. Pressing this button actuates the switch, regardless

of the state of ow. Pumping systems can be manually started by pressing this button and holding it in until ow is established. The override button can be used to test control circuits

and wiring during commissioning, without the need for water in the pipework. The button is spring loaded so it can’t be inadvertently left in the on position and only overrides the ow

switch while it is pressed.

Warning note on operating limitations: Maximum operating pressure of the Polypropylene F21-S must be linearly de-rated as operating temperature is increased so that at 60°C

the maximum permissible operating pressure for the switch is not more than one Bar Absolute.

INSTALLATION

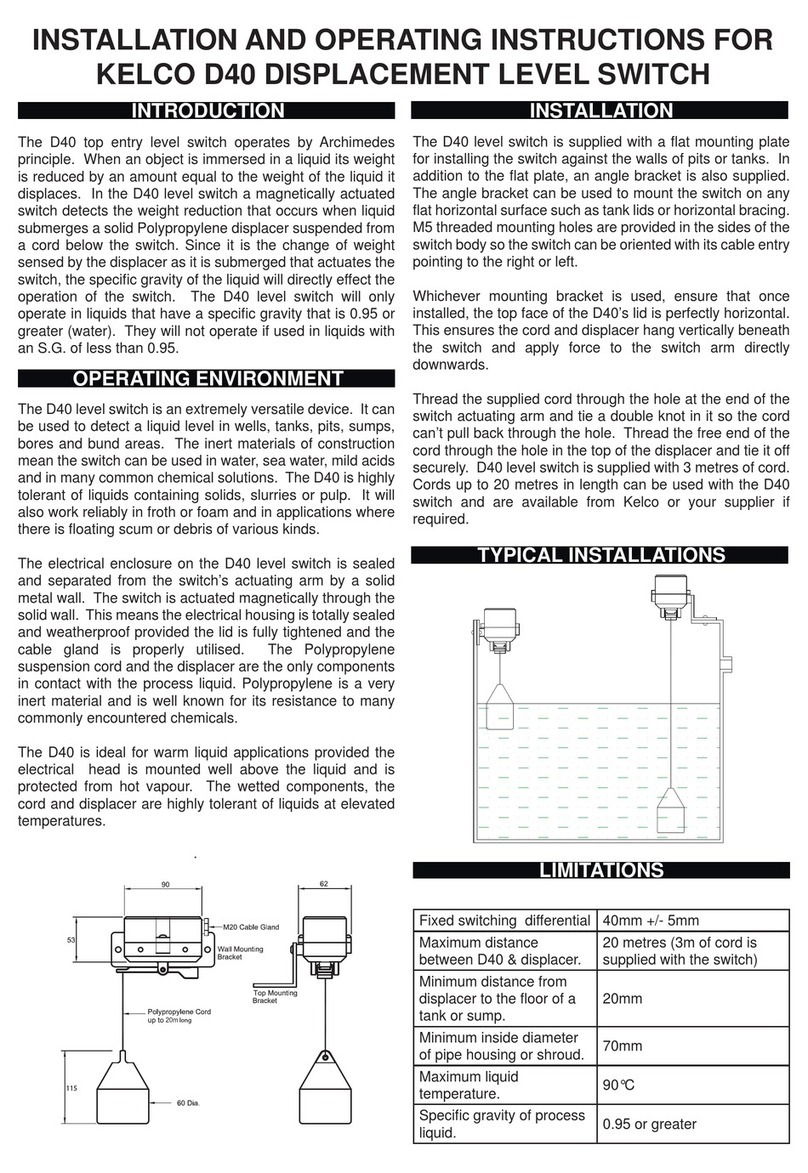

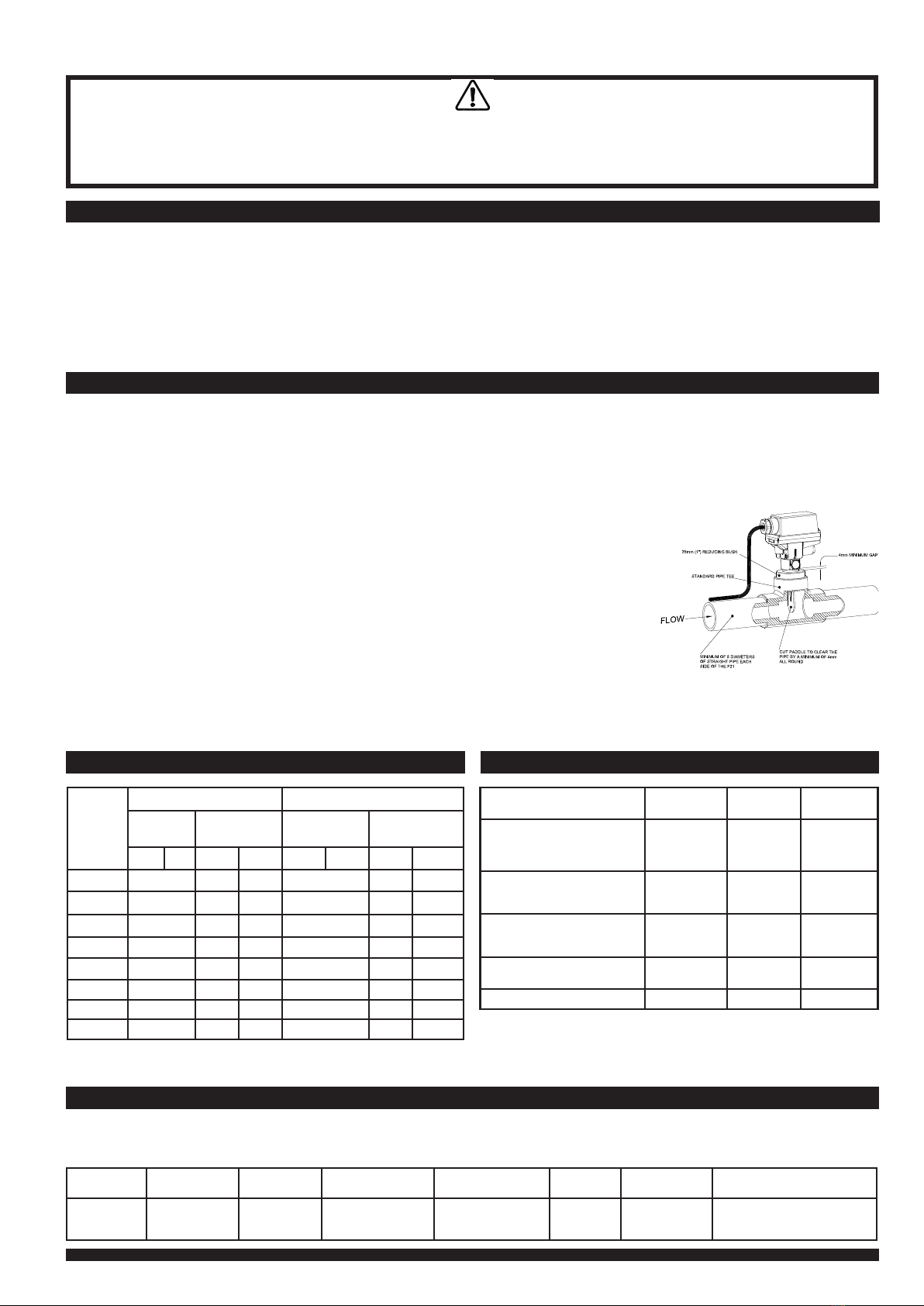

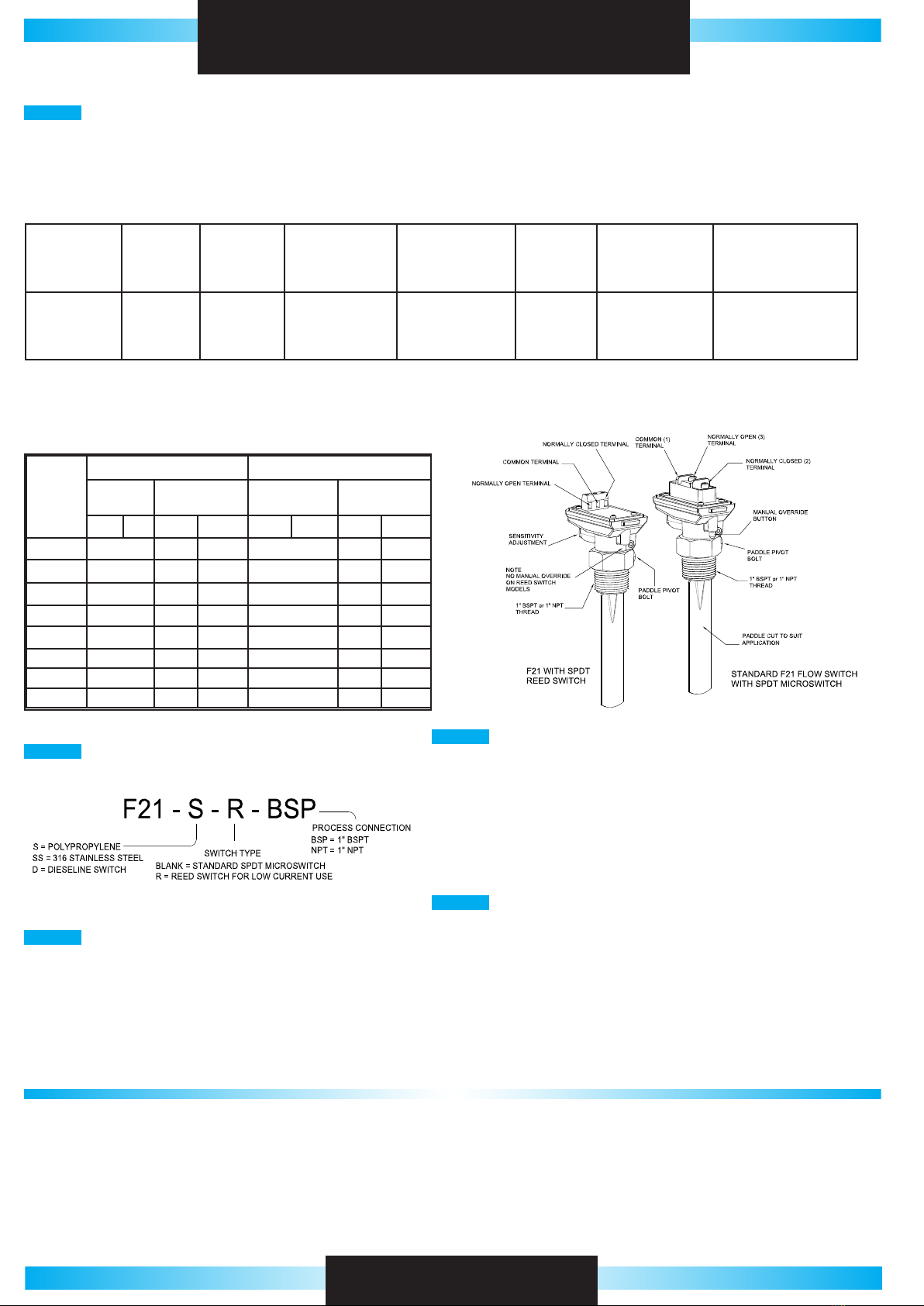

OPERATING LIMITATIONSELECTRICAL DATA MICROSWITCH MODELS

Model F21-S

(All Poly)

F21-SS

(Stainless)

F21-D

(Diesel)

Maximum operating pressure

(Static or Dynamic) at ambient

temperature

18 Bars

(261 PSI)

200 Bars

(2900 PSI)

200 Bars

(2900 PSI)

Minimum burst pressure at

ambient temperature

45 Bars

(652 PSI)

500 Bars

(7251 PSI)

500 Bars

(7251 PSI)

Maximum operating

temperature

60ºC

See note

below

80ºC 80ºC

Minimum operating

temperature

0ºC 0ºC 0ºC

Minimum liquid S.G. 0.8 0.8 0.8

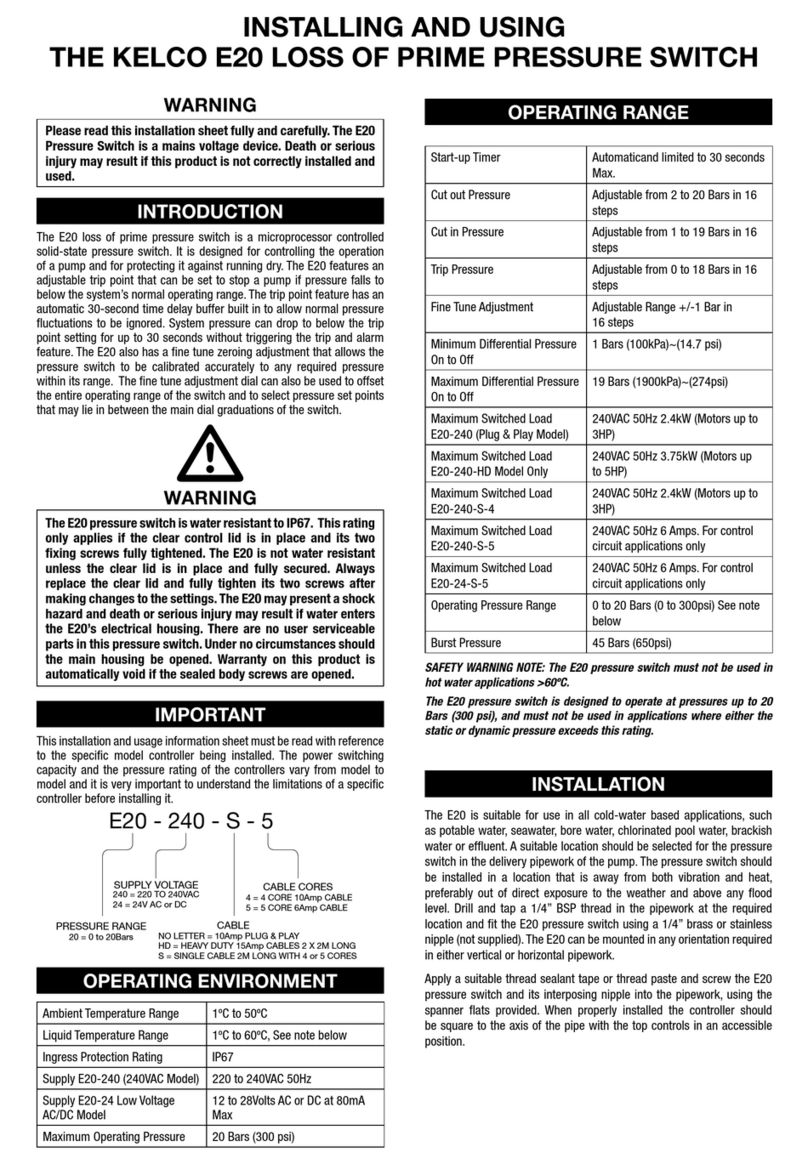

RATED

VOLTAGE

NON INDUCTIVE LOADS INDUCTIVE LOADS

RESISTIVE

LOAD

LAMP LOAD INDUCTIVE

LOAD

MOTOR LOAD

NO NC NO NC NO NC NO NC

125 VAC 15A 3A 1.5A 15A 5A 2.5A

250 VAC 15A 2.5A 1.25A 15A 3A 1.5A

500 VAC 10A 1.5A 0.75A 6A 1.5A 0.75

8 VDC 15A 3A 1.5A 15A 5A 2.5A

14 VDC 15A 3A 1.5A 10A 5A 2.5A

30 VDC 6A 3A 1.5A 5A 5A 2.5A

125 VDC 0.5A 0.5A 0.25A 0.05A 0.05A 0.05A

250 VDC 0.5A 0.5A 0.25A 0.03A 0.03A 0.03A

SWITCH

TYPE

CONTACT SWITCHED

POWER

SWITCHED VOLTAGE

MAXIMUM

SWITCHED CURRENT

(RESISTIVE)

CARRY

CURRENT

BREAKDOWN

VOLTAGE

TYPICAL

APPLICATIONS

DRY CONTACT

REED SWITCH

S.P.D.T BREAK

BEFORE MAKE

20W / VA

MAXIMUM

140V AC

150V DC

1 AMP

MAXIMUM

2 AMP

MAXIMUM

200V MINIMUM PLC, TELEMETRY & GENERAL

LOW VOLTAGE CONTROL

APPLICATIONS

The reed switch models are supplied with a high compliance single pole double throw reed switch suitable for all low wetting current and low voltage applications. Such

applications include PLC control, signalling in telemetry systems and relay logic circuits. Note: the reed switch models are not suitable for use with inductive loads such as

contactors or high wattage relays.

ELECTRICAL DATA REED SWITCH MODELS

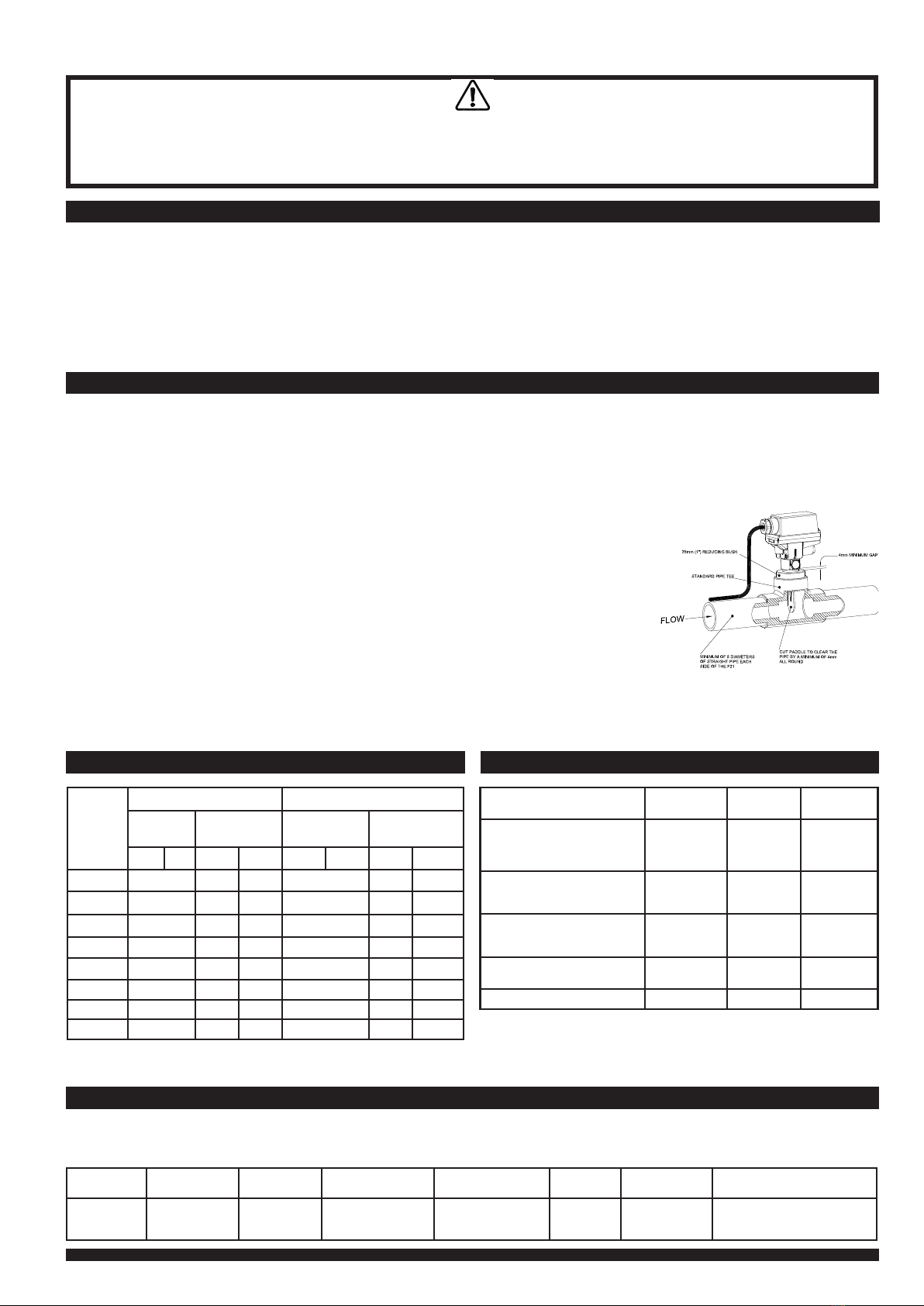

Select a location for the ow switch in a straight run of pipe, ideally with ve pipe diameters of straight pipe either side of the switch. This will ensure a linear non turbulent ow acts

against the paddle of the switch. Do not install the ow switch in any location likely to expose it to turbulence, such as close to valves, pumps or pipe bends The idea is to install the

switch in a location where there is a smooth ow of liquid past the paddle, and to obtain a stable non-chattering response from the ow switch. The F21 ow switch can be mounted in

either the suction or discharge pipe of a pump, the switch will work equally well in positive or negative pressure applications.

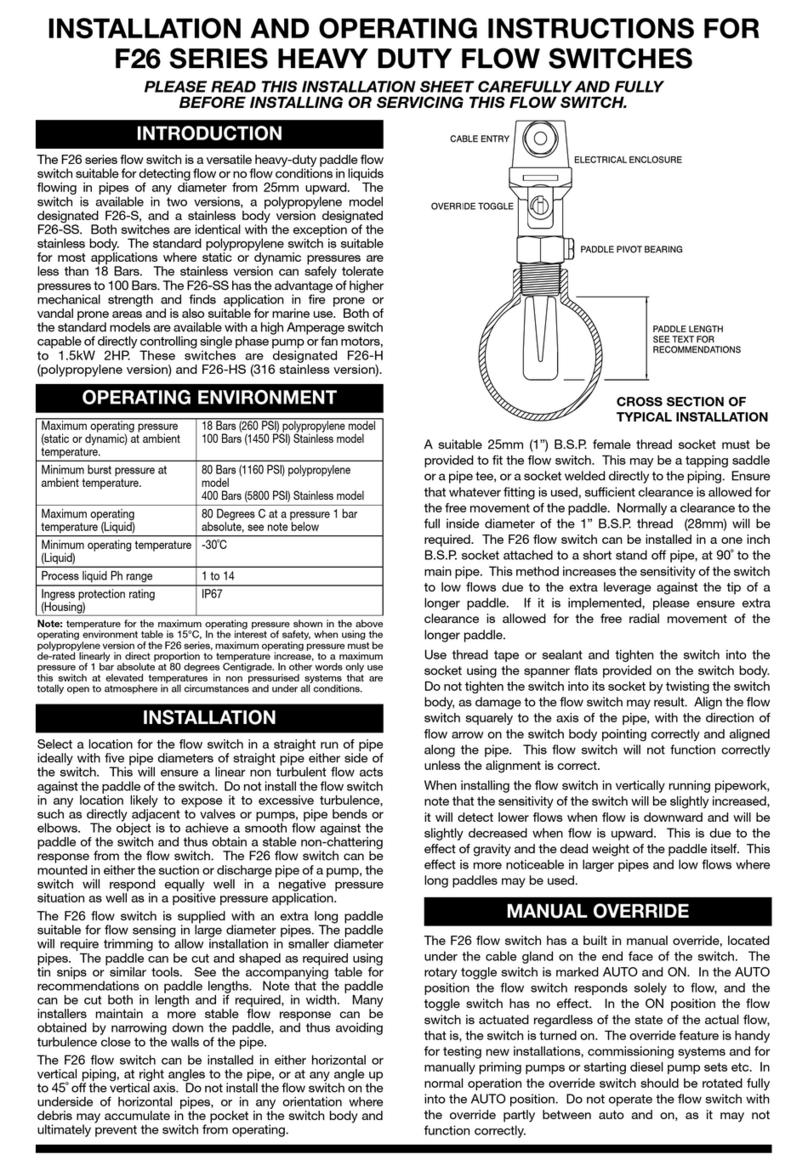

The F21 ow switch has an extra long paddle so it can be used in large diameter pipes. The paddle will require trimming if the ow

switch is to be used in smaller diameter pipes. The paddle can be cut and shaped as required using tin snips or a hacksaw. Note, the

paddle can be cut both in length and if required, in width. Many installers maintain a more stable ow response can be obtained by

narrowing down the paddle and avoiding turbulence close to the walls of the pipe. The F21 ow switch can be installed in any required

orientation except on the under side of horizontal pipes.

Depending on the thread on the switch, a 25 mm, 1” BSP or 1” NPT threaded socket must be provided on the piping, to t the ow

switch. This may be a tapping saddle or a pipe tee tted with a threaded reducing bush, or a socket welded directly to the pipe. Ensure

that whatever tting is used, sufcient clearance is allowed for the free movement of the paddle. Normally a clearance to the full inside

diameter of the 1” pipe thread will be required. The F21 ow switch can be installed in a 1” pipe socket attached to a short stand off

pipe, at 90° to the main pipe. This method of mounting increases the sensitivity of the switch to low ows due to the extra leverage

against the tip of a longer paddle. If this mounting method is used make sure to leave extra clearance to allow for the full arc movement

of the longer paddle.

Use a suitable thread sealant and tighten the switch into the socket using the spanner ats provided on the switch body. Do not tighten

the switch into its socket by twisting the electrical housing of the switch, as damage to the ow switch may result. Align the ow switch

squarely to the axis of the pipe, with the direction of ow arrow on the side of the switch body parallel to the axis of the pipe and aligned

in the direction of ow. The F21 will not function correctly unless alignment is correct. When installing the ow switch in vertically

aligned pipework, the sensitivity of the switch will be slightly increased; it will detect lower ows when ow is downward, and the

sensitivity will be slightly decreased when ow is upward. This is due to the effect of gravity on the dead weight of the paddle itself.

This effect is more noticeable in larger pipes and low ows where long paddles may be used.

WARNING

Please read these installation and operating instructions fully and carefully before installing or servicing this level switch. The F21 Series ow switch is

mains voltage device. Death or serious injury may result if this switch is not correctly installed and operated. All electrical work must be performed by

a fully qualied and licenced electrician.

Vendor Manual - Heavy Duty Flow Switch - Kelco - Model F21 - Installation Operation and Maintenance Manual