9

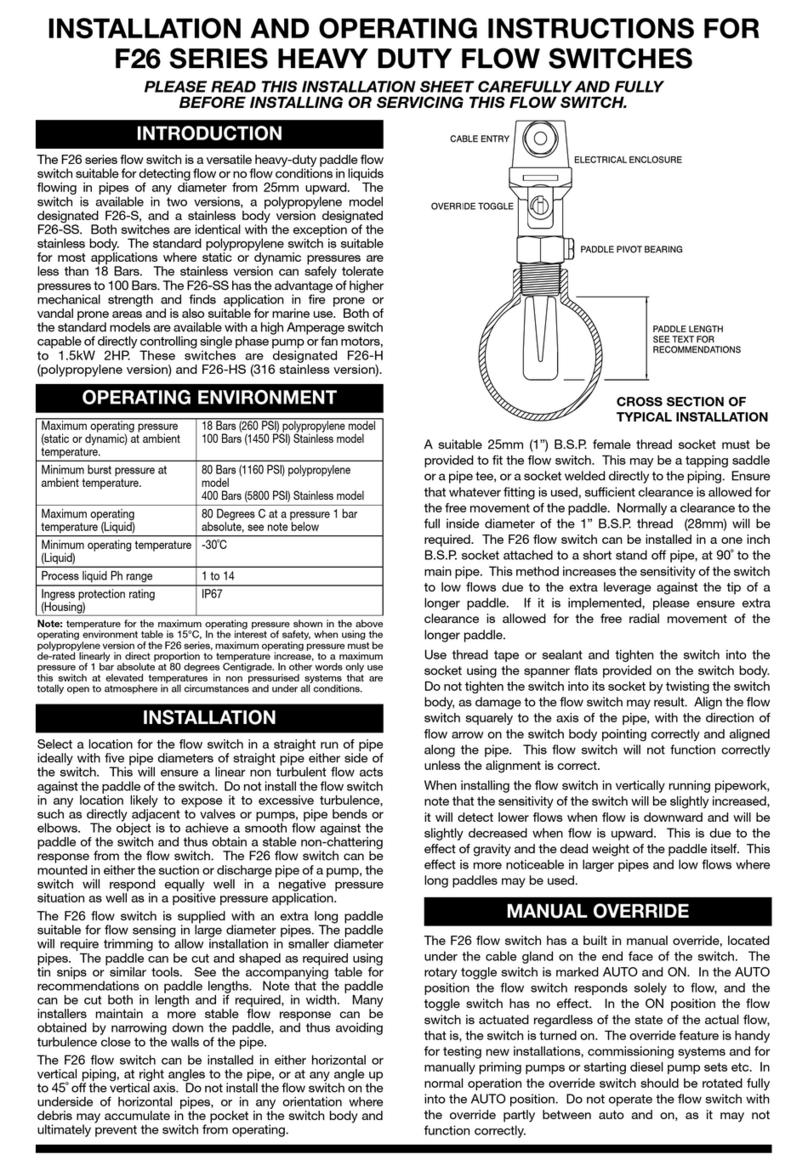

FITTING THE PADDLE ASSEMBLY

To fit the paddle assembly into the pipework, apply Teflon tape or thread

sealing compound to the thread and use a suitable spanner and the

spanner flats provided on the paddle assembly (directly above the process

connection thread). Under no circumstances should the electrical housing

be twisted or used to screw the paddle assembly into the pipework or to

align the F29 with the axis of the pipework. To do so will irreparably damage

the F29 and void its warranty. When correctly installed there should be a

minimum 4mm gap between the top of the pipe socket and the top of the

thread on the F29. The F29 can be installed in either vertical or horizontal

pipe. The F29 has a 1” BSP or NPT process connection. A matching

female threaded socket, pipe saddle or pipe tee must be provided to fit the

F29 into the pipework.

ATTACHING THE ELECTRICAL HOUSING

There is a flat keying face on the cylindrical body of the paddle assembly

that keys the electrical housing onto the paddle assembly and aligns it

correctly. It is critical that the keying flat is on the downstream side and at

90 degrees to the axis of the pipework (see sketch). To secure the electrical

housing onto the paddle assembly an Allen head cap screw is supplied.

The cap screw should be screwed fully through the hole provided on the

underside of the electrical housing and should be securely tightened using

a 3mm A/F Allen key (supplied).

DETACHING THE ELECTRICAL HOUSING

To allow easy access to the flow switch’s paddle, the electrical housing of

the F29 can be detached from the paddle assembly. Removing the

electrical housing allows access to the paddle without the need to disconnect

the electrical connections to the F29. To remove the electrical assembly,

switch off the system’s power and undo and completely remove the locking

screw (see diagram). Once the locking screw is removed, lift the electrical

housing straight off (do not twist it when doing this). Once the electrical

housing has been removed, the paddle assembly can be unscrewed from

the pipework using the spanner flats on the body of the assembly. Simply

reverse this procedure to refit the electrical housing to the F29.

SENSITIVITY ADJUSTMENT

Under the end of the electrical housing on the F29 is a red hexagonal dust

cap. If you remove this dust cap you gain access to an adjustment screw