The F26 series flow switch is a versatile heavy-duty paddle flow

switch suitable for detecting flow or no flow conditions in liquids

flowing in pipes of any diameter from 25mm upward. The

switch is available in two versions, a polypropylene model

designated F26-S, and a stainless body version designated

F26-SS. Both switches are identical with the exception of the

stainless body. The standard polypropylene switch is suitable

for most applications where static or dynamic pressures are

less than 18 Bars. The stainless version can safely tolerate

pressures to 100 Bars. The F26-SS has the advantage of higher

mechanical strength and finds application in fire prone or

vandal prone areas and is also suitable for marine use. Both of

the standard models are available with a high Amperage switch

capable of directly controlling single phase pump or fan motors,

to 1.5kW 2HP. These switches are designated F26-H

(polypropylene version) and F26-HS (316 stainless version).

Note: temperaturefor the maximum operating pressure shown in the above

operating environment table is 15°C, In the interest of safety, when using the

polypropylene version of the F26 series, maximum operating pressuremust be

de-rated linearly in direct proportion to temperature increase, to a maximum

pressure of 1 bar absolute at 80 degrees Centigrade. In other words only use

this switch at elevated temperatures in non pressurised systems that are

totally open to atmospherein all circumstances and under all conditions.

Select a location for the flow switch in a straight run of pipe

ideally with five pipe diameters of straight pipe either side of

the switch. This will ensure a linear non turbulent flow acts

against the paddle of the switch. Do not install the flow switch

in any location likely to expose it to excessive turbulence,

such as directly adjacent to valves or pumps, pipe bends or

elbows. The object is to achieve a smooth flow against the

paddle of the switch and thus obtain a stable non-chattering

response from the flow switch. The F26 flow switch can be

mounted in either the suction or discharge pipe of a pump, the

switch will respond equally well in a negative pressure

situation as well as in a positive pressure application.

The F26 flow switch is supplied with an extra long paddle

suitable for flow sensing in large diameter pipes. The paddle

will require trimming to allow installation in smaller diameter

pipes. The paddle can be cut and shaped as required using

tin snips or similar tools. See the accompanying table for

recommendations on paddle lengths. Note that the paddle

can be cut both in length and if required, in width. Many

installers maintain a more stable flow response can be

obtained by narrowing down the paddle, and thus avoiding

turbulence close to the walls of the pipe.

The F26 flow switch can be installed in either horizontal or

vertical piping, at right angles to the pipe, or at any angle up

to 45˚ off the vertical axis. Do not install the flow switch on the

underside of horizontal pipes, or in any orientation where

debris may accumulate in the pocket in the switch body and

ultimately prevent the switch from operating.

Asuitable 25mm (1”) B.S.P. female thread socket must be

provided to fit the flow switch. This may be a tapping saddle

or a pipe tee, or a socket welded directly to the piping. Ensure

that whatever fitting is used, sufficient clearance is allowed for

the free movement of the paddle. Normally a clearance to the

full inside diameter of the 1” B.S.P. thread (28mm) will be

required. The F26 flow switch can be installed in a one inch

B.S.P. socket attached to a short stand off pipe, at 90˚ to the

main pipe. This method increases the sensitivity of the switch

to low flows due to the extra leverage against the tip of a

longer paddle. If it is implemented, please ensure extra

clearance is allowed for the free radial movement of the

longer paddle.

Use thread tape or sealant and tighten the switch into the

socket using the spanner flats provided on the switch body.

Do not tighten the switch into its socket by twisting the switch

body,as damage to the flow switch may result. Align the flow

switch squarely to the axis of the pipe, with the direction of

flow arrow on the switch body pointing correctly and aligned

along the pipe. This flow switch will not function correctly

unless the alignment is correct.

When installing the flow switch in vertically running pipework,

note that the sensitivity of the switch will be slightly increased,

it will detect lower flows when flow is downward and will be

slightly decreased when flow is upward. This is due to the

effect of gravity and the dead weight of the paddle itself. This

effect is more noticeable in larger pipes and low flows where

long paddles may be used.

The F26 flow switch has a built in manual override, located

under the cable gland on the end face of the switch. The

rotary toggle switch is marked AUTO and ON. In the AUTO

position the flow switch responds solely to flow, and the

toggle switch has no effect. In the ON position the flow

switch is actuated regardless of the state of the actual flow,

that is, the switch is turned on. The override feature is handy

for testing new installations, commissioning systems and for

manually priming pumps or starting diesel pump sets etc. In

normal operation the override switch should be rotated fully

into the AUTO position. Do not operate the flow switch with

the override partly between auto and on, as it may not

function correctly.

INSTALLATION AND OPERATING INSTRUCTIONS FOR

F26 SERIES HEAVY DUTY FLOW SWITCHES

PLEASE READ THIS INSTALLATION SHEET CAREFULLY AND FULLY

BEFORE INSTALLING OR SERVICING THIS FLOW SWITCH.

INTRODUCTION

OPERATING ENVIRONMENT

INSTALLATION

Maximum operating pressure

(static or dynamic) at ambient

temperature.

Minimum burst pressure at

ambient temperature.

Maximum operating

temperature (Liquid)

Minimum operating temperature

(Liquid)

Process liquid Ph range

Ingress protection rating

(Housing)

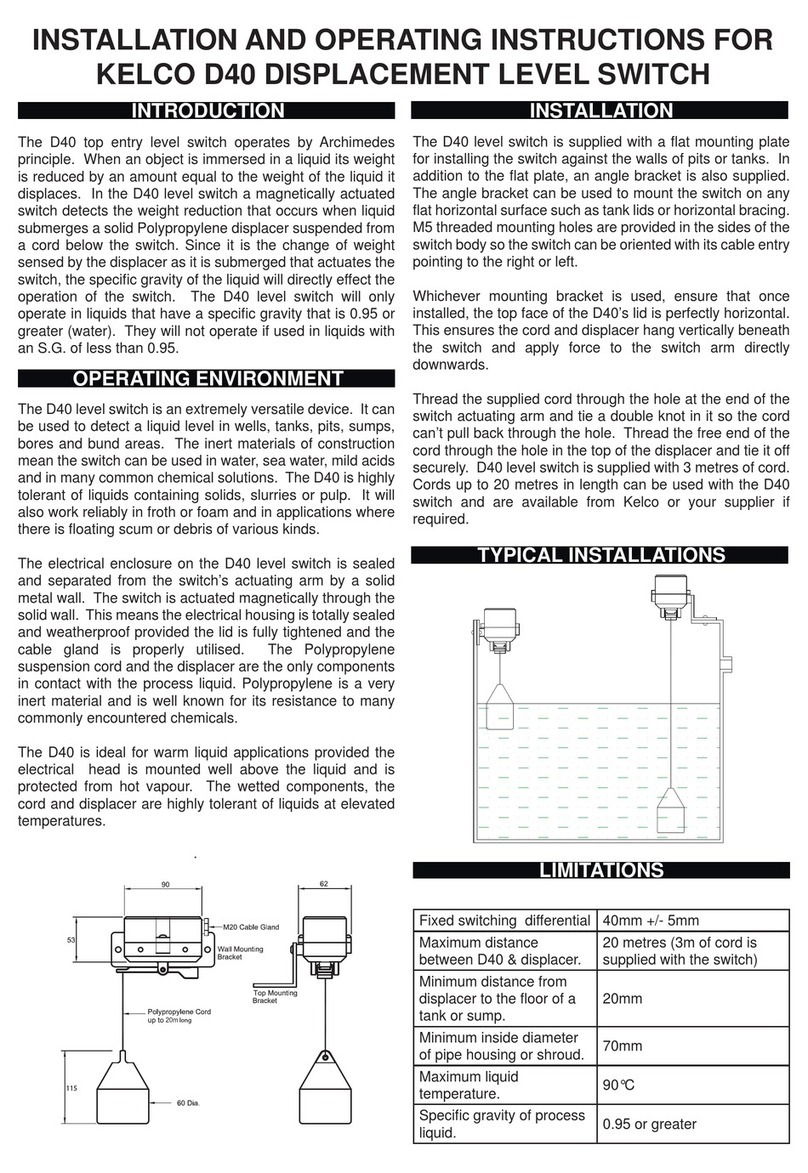

CROSS SECTION OF

TYPICAL INSTALLATION

MANUAL OVERRIDE

18 Bars (260 PSI) polypropylene model

100 Bars (1450 PSI) Stainless model

80 Bars (1160 PSI) polypropylene

model

400 Bars (5800 PSI) Stainless model

80 Degrees C at a pressure 1 bar

absolute, see note below

-30˚C

1to 14

IP67