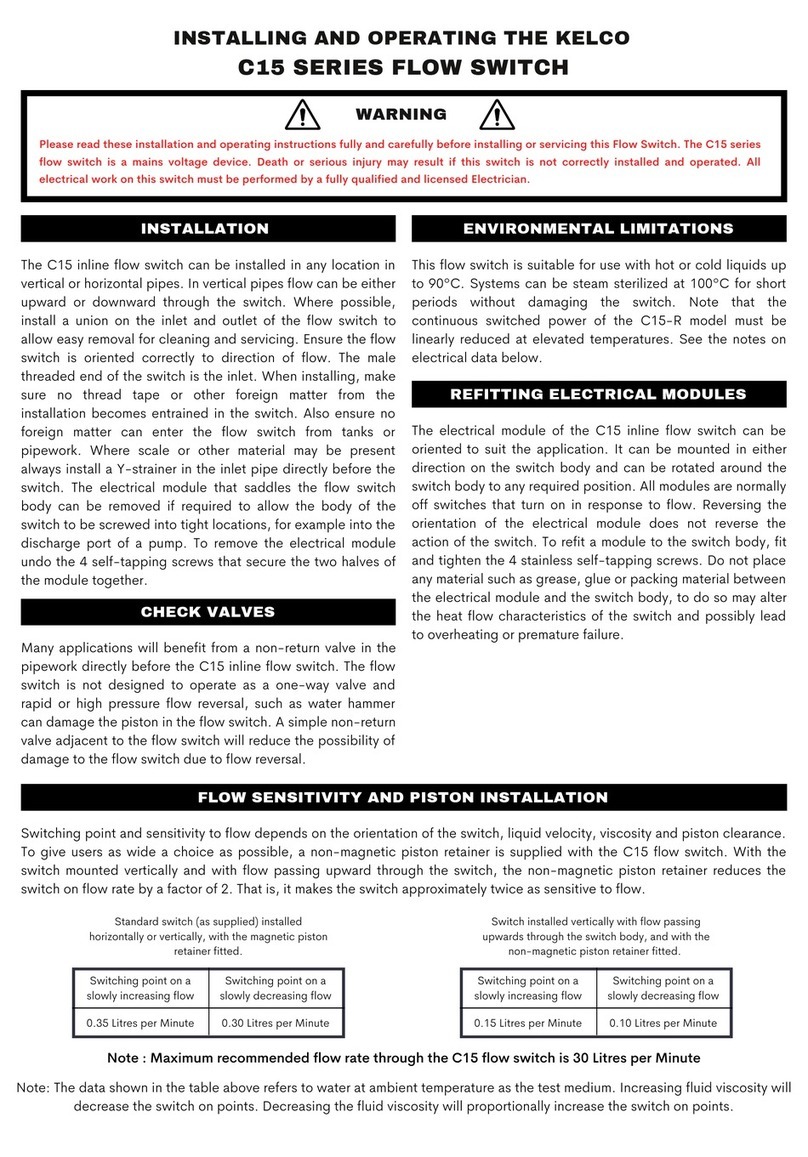

ELECTRICAL

This ow switch can be supplied with one of four optional

electrical modules. The details of the various modules are

set out in the table below. The model of the switch and its

electrical module is indicated by a label xed to the inside of

the electrical enclosure of every switch.

MAINTENANCE

Please Note: All UB25 series ow switches use reed switches as the primary switching element. Reed switches are one of

the most reliable mechanical switching devices ever devised. They offer an operating life in excess of 100 million cycles,

however, care needs to be taken to ensure they are not electrically overloaded or if applied in questionable applications,

suitable protection should be added to the control circuit.

If the UB25 ow switch is correctly installed and if the process uid is compatible with the materials of construction of this

switch, then a very long maintenance free service life can be expected. Factors that may contribute to early failure of this

ow switch include excess temperature, excess pressure or electrical loads in excess of the circuit boards rating.

To service the piston or to install the non-magnetic piston retainer, Use a pair of long nosed pliers to remove the spring

Circlip located in the outlet port of the switch. Press the piston back with your nger, it should pop out along with its three

nned magnetic spider. Ensure there are no pieces of iron scale adhered to the piston or spider and that both parts are free

of damage. Reassemble the switch and test it to ensure the piston is a free and smooth t.

Most component of this switch are available in spare part kits.

ELECTRICAL DATA

WARNING

All electrical work associated with the UB25 Series in line

Flow Switch must be carried out by qualied electrical

personnel and all electrical work must conform to AS/NZ

(or equivalent) standards and to local wiring rules.

MODEL MODULE

TYPE

CONTACT

CONFIGURATION

SWITCHED

POWER

MAXIMUM

SWITCHED

VOLTAGE

MAXIMUM

SWITCHED

CURRENT

RESISTIVE AC

(RMS) MAXIMUM

INDUCTIVE LOADS

(POWER FACTOR

0.4)

TYPICAL APPLICATION

UB25-B Dry Reed

Switch

S.P.S.T N.O 40W 240V AC

200V DC

1 Amp Not Suitable PLC and General

Control Circuits

UB25-C Dry Reed

Switch

S.P.D.T.

Break Before Make

20W 140V AC

150V DC

1 Amp Not Suitable PLC Control and

Safety Showers

UB25-R Solid State

Relay

S.P.S.T. 750W 12 TO 240V

AC

Spike to 40 Amp 4A at 240V AC

AC Control Circuits and

AC Motor Control to a

Maximum of 1 HP, 0.75KW

KELCO Engineering Pty Ltd

ABN 20 002 834 844 Head office and factory: 9/9 Powells Road Brookvale NSW 2100 Australia. Postal Address: PO Box 7485 Warringah Mall Post

Shop Brookvale NSW 2100

Australia.

Phone: +61 2 9905 6425

Fax: +61 2 9905 6420

Email: [email protected] Web: www

.Kelco.com.au

PLEASE NOTE: Kelco Engineering Pty Ltd reserves the right to change the specication of this product without notice. Kelco Engineering Pty Ltd accepts no liability for personal injury or economic loss as

a consequence of the use of this product. All rights reserved copyright Kelco Engineering Pty Ltd © 2014 The Kelco UB25 is protected by a 12 month return to base warranty. Full details of our warranty

can be downloaded from: http://www.kelco.com.au/warranty