4© Kemppi Oy 2022

1. Introduction

1.1 Zeta W200 and W200x

Zeta W200 and W200x welding helmets are designed for

arc welding (MMA, MIG/MAG, TIG), grinding, gouging and

plasma cutting.

Zeta W200 and W200x welding helmets provide the users

with protection for the eyes and face. The helmets are

equipped with auto-darkening lter ADF SA 60Z, and the

Zeta W200x model has also integrated LED work lights.

1.2 About this manual

Read this manual carefully before using the equipment for

the rst time. Pay particular attention to the safety instruc-

tions.

Note Gives the user a piece of

information of particular

importance.

Caution Describes a situation that

may result in damage to the

equipment or system.

Warning Describes a potentially dangerous

situation that may result in

personal damage or fatal injury.

1.3 Disclaimer

While every eort has been made to ensure that the infor-

mation contained in this guide is accurate and complete,

no liability can be accepted for any errors or omissions.

Kemppi reserves the right to change the specication of

the product described at any time without prior notice. Do

not copy, record, reproduce or transmit the contents of this

guide without prior permission from Kemppi.

2. Safety

Warning:

• It is strictly forbidden to use any other than Kemppi

branded parts or accessories with Kemppi’s person-

al protection equipment. If you do not respect this

safety regulation, serious damage for your health

may occur.

• We recommend a usage period of 5 years. The

period of use depends on various factors such as

use, cleaning, storage and maintenance. Inspect the

helmet before each use. Replace damaged or worn

parts.

• Use all adjustment features for maximum protection.

• Never weld with the welding visor up or without the

• welding lter.

• If the auto-darkening lter (ADF) does not darken

when the arc ignites, stop welding immediately.

Inspect the ADF and its power supply. Change if

necessary.

• Always use welding lters together with suitable pro-

tection plates.

• Never use welding lter without inner protection

plates.

• Never use a scratched or damaged welding lter and

ocular.

• Materials which may come into contact with the

wearer’s skin may cause allergic reactions to suscep-

tible individuals.

• Only operate this product within the temperature

range -5...+55 °C.

• The product is not intended for use in environments

with a risk of explosion.

• The helmet does not protect against explosive

devices or corrosive liquids.

• The helmet is not suitable for laser welding and

oxyacetylene welding/cutting processes.

• The helmet gives designed protection against high

speed particles only at room temperature (EN175

designation B) and only when all helmet components

are properly attached, as described in the manual.

• When helmet is worn over any spectacles, they may

transmit the impact of high speed particles, thus

creating a hazard to the wearer.

• If the symbols of the marking are not common to

dierent parts of the protection equipment, the

lower protection level shall be assigned to the

complete protection equipment.

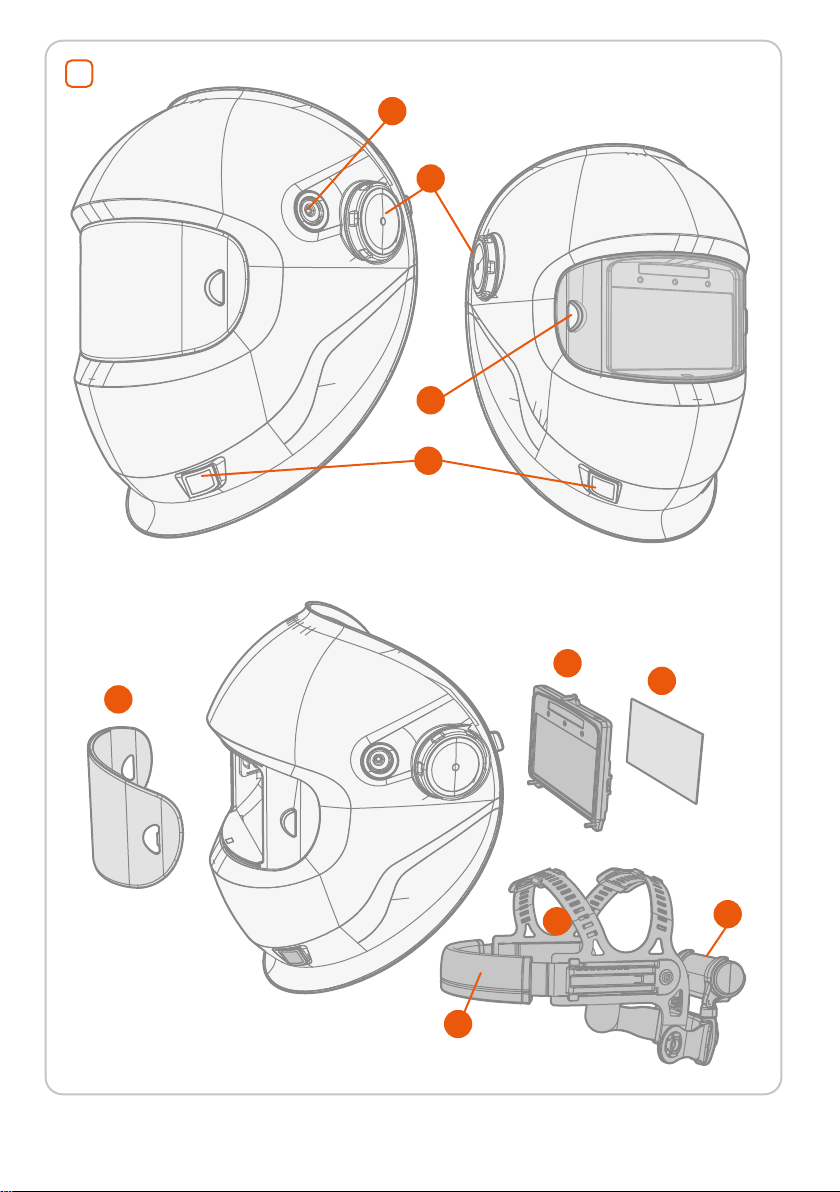

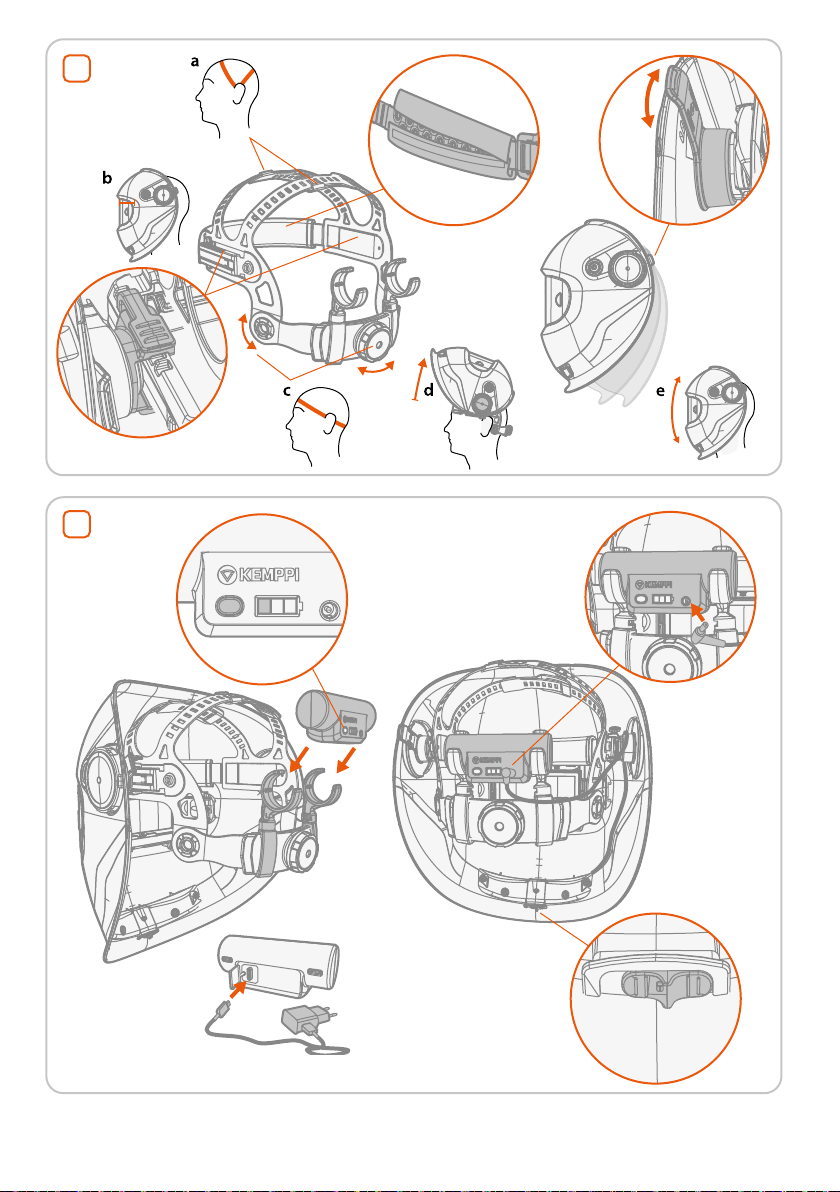

3. Parts 12345

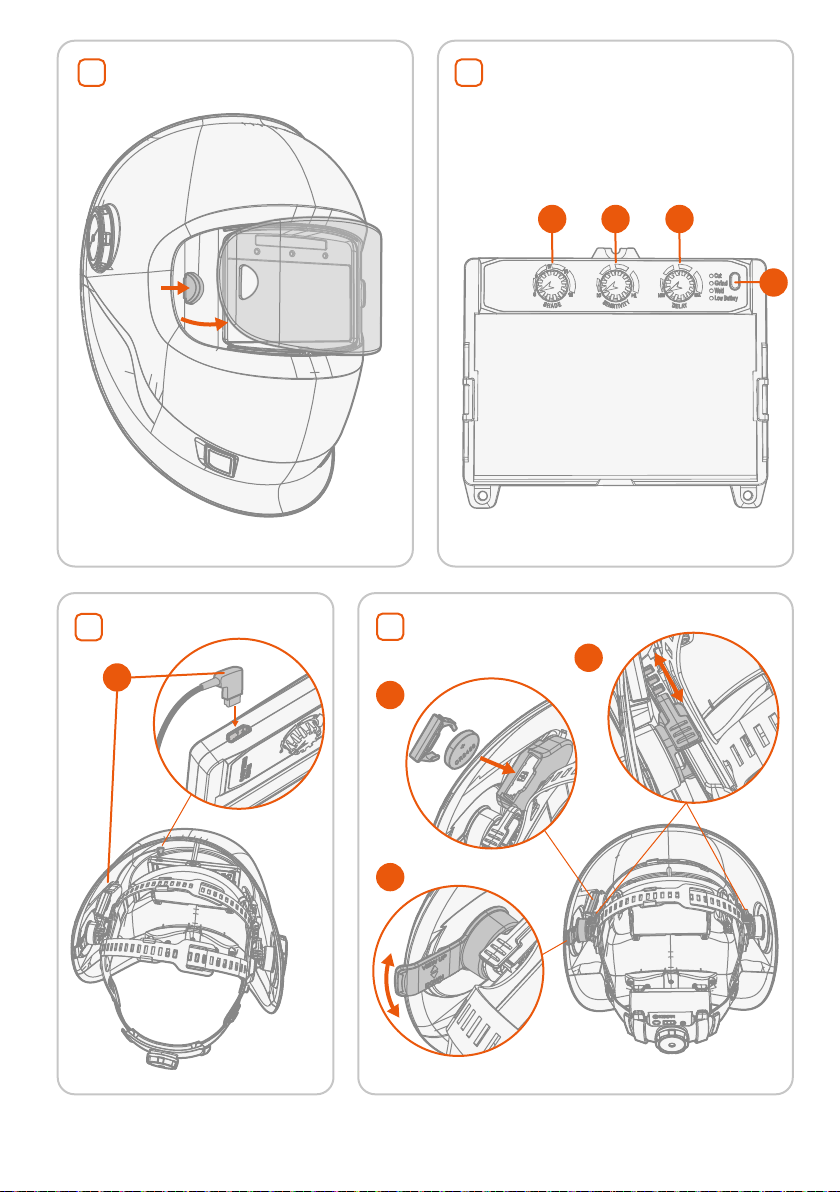

1. Opening/closing tightness adjuster

2. Grinding mode (clear view) button

3. LED work lights (W200x model only)

4. Protection plate release button

5. Protection plate

6. Auto-darkening welding lter (ADF SA 60Z)

7. Inner protection plate

8. Headband, adjustable

9. Sweatband, washable

10. LED work light Li-ion battery unit (W200x model

only)

11. ADF: Shade adjustment

12. ADF: Sensitivity adjustment

13. ADF: Delay adjustment

14. ADF: Operation mode selector (Cut/Grind/Weld)

15. ADF: Battery connection

16. ADF battery and battery holder

17. Distance slide adjusters (connect the headband to

the helmet and adjust the distance of the helmet

from the face)

18. Viewing angle adjuster.

ENGLISH