General precautions for use:

1. Keep the machine out of the reach of children.

2. High-pressure water jets must not be directed against persons or animals, electrical equipment of

the machine itself. Do not use the machine when persons and/or animals are within the reach of

the jet.

3. The user must operate the machine in safe conditions and situations avoiding any situations of

potential danger to himself or other persons, in particular, the user will have to:

-Avoid operating in unstable balance conditions.

-Remember that the high pressure generates a recoil when the gun is operated. The force of this

recoil is less than 20 N (approx. 2 kg).

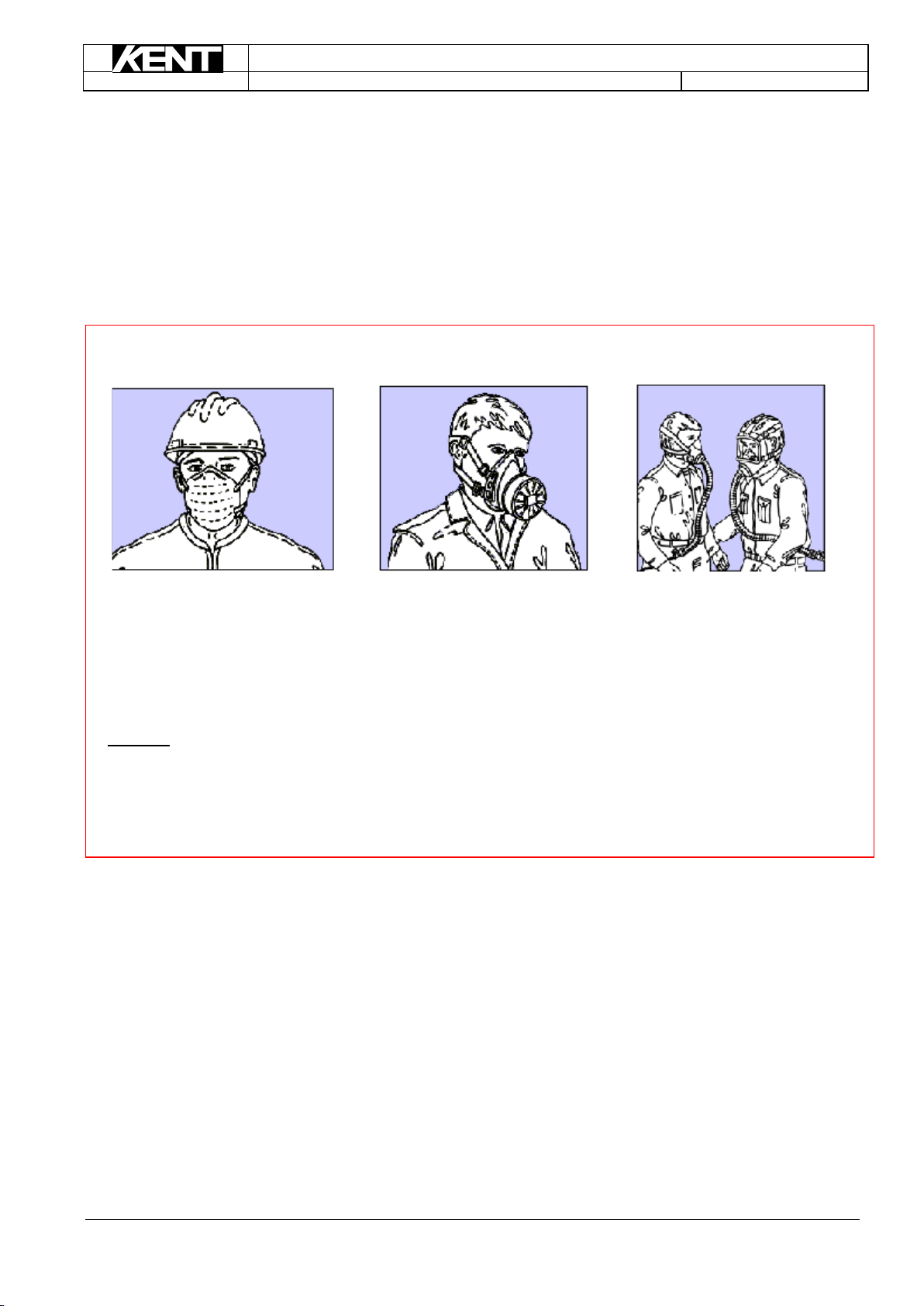

-Use adequate protection clothing.

-Wear protection goggles and anti-slip rubber shoes.

- Avoid contaminating the environment with pollution, toxic or harmful substances.

4. This machine is built in compliance with the requirements of the current safety regulations. In any

case the use of electrical appliances involves the respect of some basic rules, namely:

- Do not touch electrical parts or components.

-All inspection, maintenance or repair operations must be made by qualified personal only. In

any case always disconnect the plug from mains before proceeding on any of the above

mentioned operations.

-In case you need to use an extension cord, check that the connection is water tight. Keep all

connections off the ground to avoid possible contacts with water.

5. Do not pull power cord to unplug.

6. While the machine is running, do not cover it and do not place it in a closed space with insufficient

ventilation.

7. Do not leave the machine running for more than 5 minutes with the gun closed. Should it run for a

longer period, the temperature of the recirculating water will increase rapidly and could risk

damaging the pump seals.

8. When the machine is not in use, lock gun trigger in safe position to prevent it form being opened by

accident.

9. For sake of safety use only original spare parts and accessories

- Should you need to remove or change the nozzle, turn off the machine and bleed pressure from

the hose.

Precautions for storage/frost:

We recommend filling the pump with anti-freeze equal to anti-freeze for cars if the machine will be stored

in a place with a risk of being exposed to frost, or will not be used for more than 3 months. In case of low

temperatures some parts may freeze or settle if the machine has been stored for a long time. Thus, we

recommend that you turn the shaft by the key supplied with the machine prior to start-up. This procedure

allows you to check if the machine is frozen or blocked by other reasons. By taking these precautions

prior to start-up you can avoid destroying the machine. Please remember to remove the key from the

shaft prior to start-up.