2228-1600 REV 3 010510

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

FEATURES

•Wide Range Input - Operates from input voltage range of 85 to 265V a-c, input frequency range 47-66Hz (see Table 1, Note

1) with no adjustment or modification required.

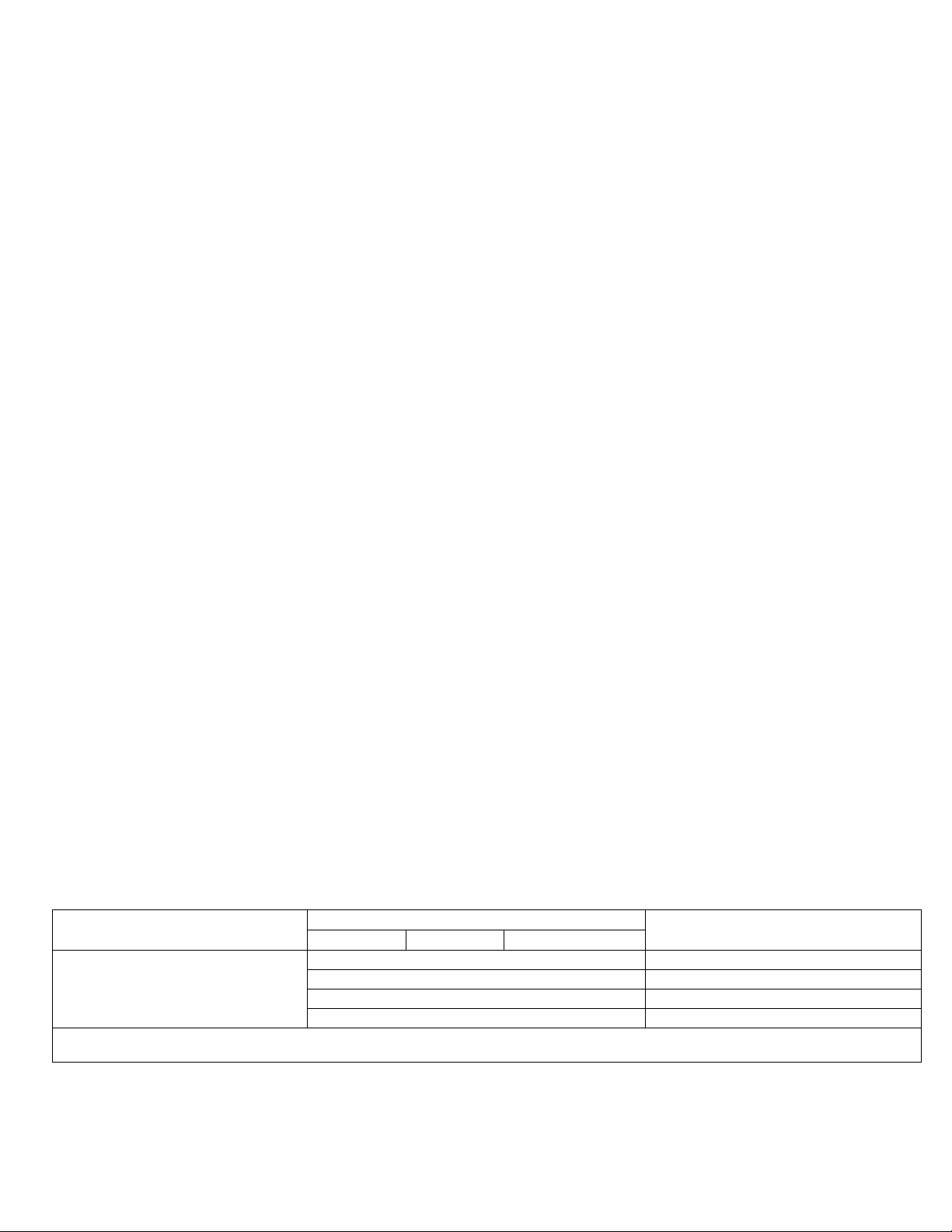

•Adjustable Float Voltage - The float voltage is adjustable over a wide range (see Table 1 for adjustment range and factory

setting). Adjust the output voltage from the front panel using the tool on the back of the front panel door (see Figure 1) to

adjust the V. FLOAT ADJ potentiometer while monitoring the + and – VOLTAGE MONITOR test points with a precision digital

voltmeter.

•Adjustable Current Limit - The current limit is adjustable over a wide range (see Table 1 for adjustment range and factory

setting). Adjust from the front panel using the C. LIMIT ADJ potentiometer using the tool on the back of the front panel door

(see Figure 1).

•Temperature Compensation - Optional temperature compensation probes (Models TEMPCO-10 (10 ft. long), TEMPCO-50

(50 ft.), TEMPCO-100 (100 ft.) and TEMPCO-200 (200 ft.), not supplied) provide automatic adjustment of the float voltage to

accommodate temperatures from 0° to 35°C for lead-acid batteries. For other lengths, consult factory.

•CHARGER ON indicator - on while a-c input power applied to unit and unit is operational.

•Charging Current ammeter - indicates charging current

•Input protection - Two line fuses are provided.

•Battery connection protection - If battery connections are reversed, an internal diode network across the output is forward

biased; the resulting current flow causes the front panel circuit breaker to pop open. The connections must be switched and

the circuit breaker pushed in to reset.

•Form C Relay Contact - Used for Battery Charger fault alarm.

•ON-OFF Control - Local On-Off circuit breaker and isolated Remote On-Off control of Battery Charger output.

II — INSTALLATION

If desired, the battery charger output voltage and current limit can be preset prior to mounting at a separate location.

PRESETTING THE OUTPUT VOLTAGE (FLOAT VOLTAGE)

1. Open the access door to gain access to input/output connections by pulling the latching retainer.

2. With a-c voltage not present and the battery disconnected route the a-c source line, neutral and ground wires through the appro-

priate openings in the bottom of the chassis and secure to L (L1), N (L2), and GND terminals of the AC INPUT terminal block, respec-

tively.

3. Connect the local ground connection to the ground stud (see Figure 1) using the 10-32 x 3/8 ACF Brass Hex nut provided (Kepco P/

N 102-0007)

4. Turn a-c power on and connect a precision digital voltmeter (DVM) to the + and – VOLTAGE MONITOR test points at the front panel.

5. Monitor the DVM and set the float voltage as desired using the tool mounted on the back of the access door to adjust the V. FLOAT

ADJ potentiometer at the front panel. It is recommended that the unit be tagged with the float voltage.

6. Turn a-c power off and disconnect DVM. If unit is to be mounted at a different location, disconnect ground and a-c input connections,

then close the access door and snap in the retainer.

PRESETTING THE CURRENT LIMIT (CHARGING LIMIT CURRENT)

1. Open the access door to gain access to input/output connections by pulling the latching retainer.

2. With a-c voltage not present disconnect battery from the output terminals.

3. Place a short-circuit (jumper link, No. 8 AWG wire, minimum) between (+) and (–) DC OUTPUT terminals.

4. If not already connected, route the a-c source line, neutral and ground wires through the appropriate openings in the bottom of the

chassis and secure to L (L1), N (L2), and GND terminals of the AC INPUT terminal block, respectively.

5. Turn a-c input power on. Monitor the front panel ammeter and set the current limit as desired (see NOTE) using tool mounted on the

back of the access door to adjust the C. LIMIT ADJ potentiometer at the front panel.

NOTE: The unit incorporates a foldback characteristic for current limit to reduce power dissipation when there is a short across the

output terminals. From a shorted output (e.g., for a brand new battery), the current limit increases linearly from 10% less than

the full current limit to the full current limit as the battery charges. Consequently, if the desired current limit is ILIM, adjust for

0.9ILIM with shorted output.

6. Turn a-c power off and remove the short-circuit between (+) and (–) DC OUTPUT terminals.

MOUNTING THE BATTERY CHARGER

Two slotted holes, 8 inches apart, are provided on the upper rear chassis (See Figure 1) to wall mount the unit. The unit also has four feet

for bench top operation. The unit has forced air cooling from a single fan located within the integral RKW power supply as well as ventila-

tion holes in the chassis which must be kept clear from obstructions to ensure proper air circulation. Enough space must be provided

around the chassis to allow the hot air to exhaust from the components inside the chassis.

1. Open the access door to gain access to input/output connections by pulling the latching retainer.

2. Route the a-c source line, neutral and ground wires through the appropriate openings in the bottom of the chassis and secure to L

(L1), N (L2), and GND terminals of the AC INPUT terminal block, respectively.

3. Connect the local ground wire to the ground stud (see Figure 1) using the 10-32 x 3/8 ACF Brass Hex nut provided (Kepco P/N 102-

0007)

4. Proceed to CONNECTING THE BATTERY or, if the battery will be connected later, close the access door and snap in the retainer.