BOP-1K 042722 i

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope of Manual ..................................................................................................................................... 1-1

1.2 General Description................................................................................................................................. 1-1

1.2.1 LXI Compatibility (MEL Models) ........................................................................................................ 1-2

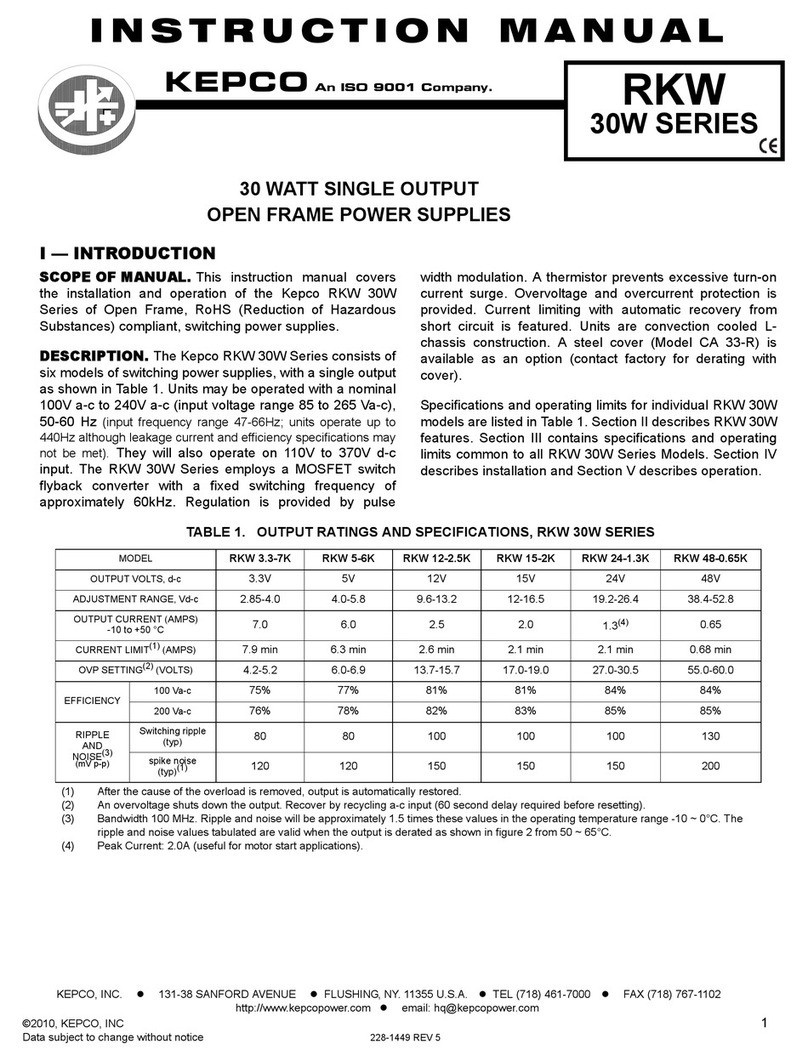

1.3 Specifications.......................................................................................................................................... 1-2

1.4 Local Control........................................................................................................................................... 1-15

1.5 Remote Control....................................................................................................................................... 1-15

1.6 Features.................................................................................................................................................. 1-18

1.6.1 Digital Calibration............................................................................................................................... 1-18

1.6.2 voltage/current Protection.................................................................................................................. 1-18

1.6.3 Waveforms......................................................................................................................................... 1-18

1.6.4 Saving and Recalling Settings........................................................................................................... 1-18

1.6.5 External Reference (Analog Control)................................................................................................. 1-18

1.6.6 External Limits................................................................................................................................... 1-19

1.6.7 User-defined Voltage/Current Maximum Values (Software Limits) ................................................... 1-19

1.6.8 Parallel and Series Configurations .................................................................................................... 1-19

1.6.9 Energy Recuperation......................................................................................................................... 1-19

1.7 Equipment Supplied................................................................................................................................ 1-19

1.8 Accessories............................................................................................................................................. 1-19

1.9 Safety...................................................................................................................................................... 1-21

SECTION 2 - INSTALLATION

2.1 Unpacking and Inspection....................................................................................................................... 2-1

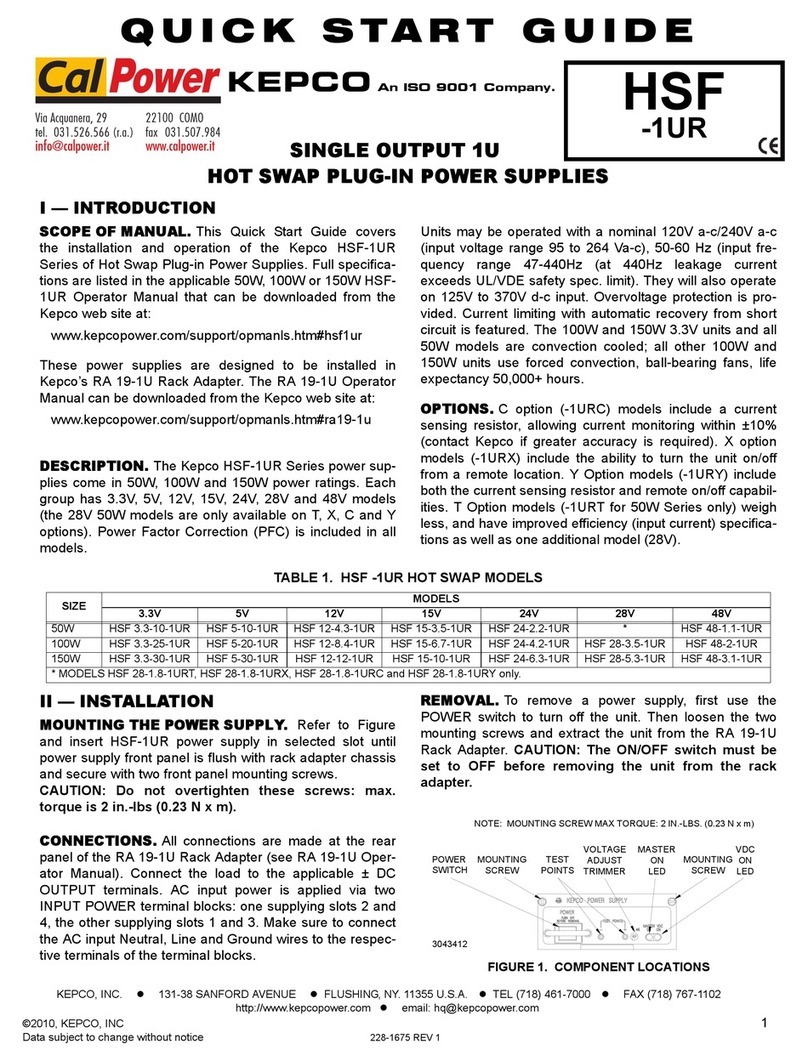

2.2 Terminations and Controls ...................................................................................................................... 2-1

2.3 Preliminary Operational Check................................................................................................................ 2-8

2.4 Installation............................................................................................................................................... 2-9

2.4.1 Rack Mounting................................................................................................................................... 2-9

2.4.2 Slide Installation................................................................................................................................. 2-9

2.5 Wiring Instructions................................................................................................................................... 2-9

2.5.1 Safety Grounding............................................................................................................................... 2-9

2.5.2 Source Power Connections............................................................................................................... 2-10

2.5.3 D-C Output Grounding....................................................................................................................... 2-10

2.5.3.1 Earth-Ground Configuration......................................................................................................... 2-11

2.5.3.2 Grounding Network Configuration................................................................................................ 2-11

2.5.4 Power Supply/Load Interface............................................................................................................. 2-11

2.5.5 Load Connection - General................................................................................................................ 2-13

2.5.6 Load Connection Using Local Sensing.............................................................................................. 2-13

2.5.7 Load Connection Using Remote Sensing.......................................................................................... 2-13

2.6 Cooling .................................................................................................................................................... 2-13

2.7 Setting up the unit ................................................................................................................................... 2-14

2.7.1 Consider the Load Type .................................................................................................................... 2-14

2.7.2 Setup for Local Operation.................................................................................................................. 2-14

2.7.3 Setup for Fail Safe/Interlock PROTECTION...................................................................................... 2-15

2.7.4 Setup for Remote Operation via GPIB (MGL Models Only) .............................................................. 2-16

2.7.5 Setup for Remote Operation via RS 232C......................................................................................... 2-16

2.7.6 Setup for Remote Operation via LAN (MEL Models Only)................................................................ 2-17

2.7.6.1 Finding Kepco Power Supplies on the LAN................................................................................. 2-17

2.7.6.2 Bonjour-enabled Discovery.......................................................................................................... 2-17

2.7.6.3 LXI Discovery............................................................................................................................... 2-18

2.7.6.4 Launch Web Interface.................................................................................................................. 2-19

2.7.6.5 LAN Configuration Using Web Interface...................................................................................... 2-20

2.8 Multiple Unit Configurations .................................................................................................................... 2-21

2.8.1 Multiple Unit Connections.................................................................................................................. 2-22

2.8.2 Multiple Unit Protection...................................................................................................................... 2-27

2.8.3 Multiple Unit Source Power............................................................................................................... 2-27

2.8.4 Configuring Parallel or Series combinations...................................................................................... 2-28