KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

083013 228-1563 REV 10 5

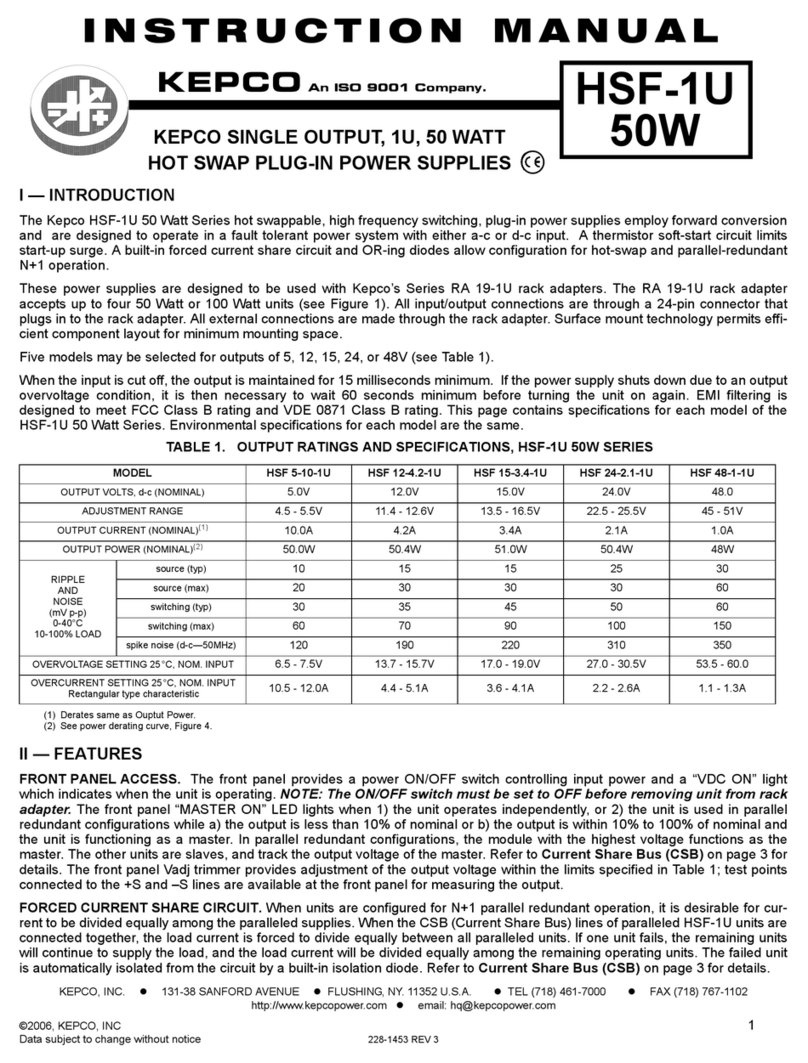

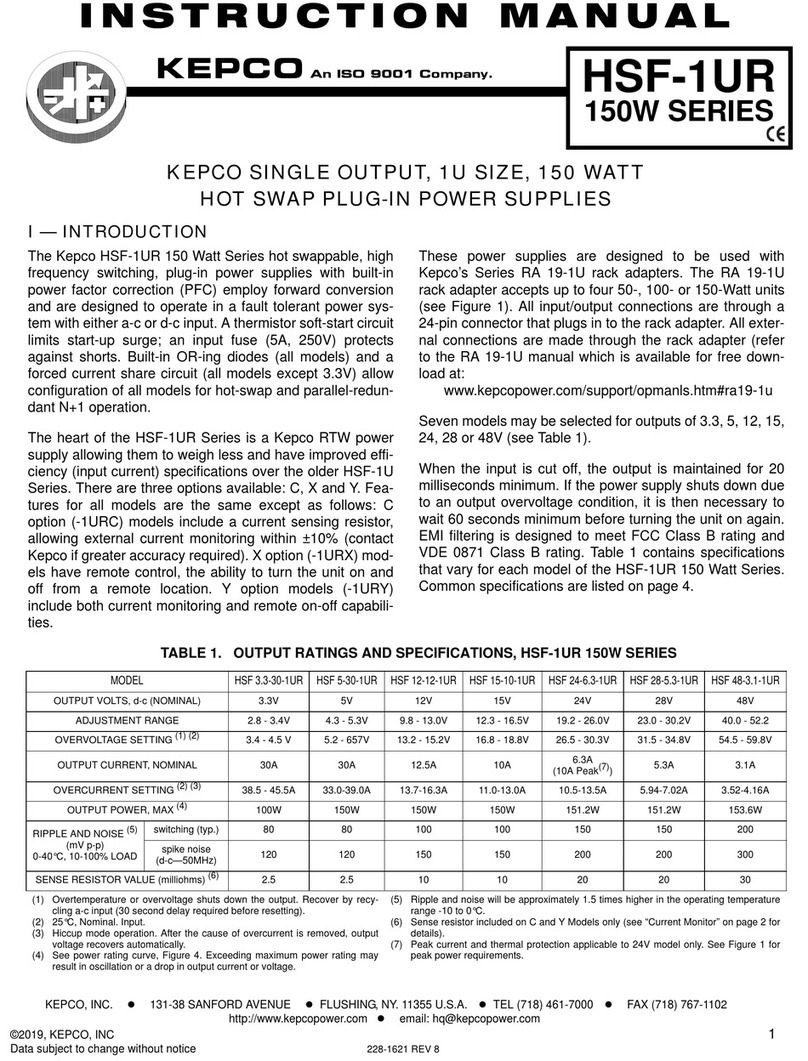

III — SPECIFICATIONS

The following specifications apply to all HSF-1UR 50 Watt

Series models (also refer to Table 1) except where noted.

Other models are also available; consult your Kepco repre-

sentative for their specifications.

INPUT:

Voltage: 120V a-c/240V a-c nominal; Range 95-264V

a-c; 125-370V d-c. (polarity insensitive; consult

factory)

Frequency: Nominal 50-60 Hz; Range 47-440Hz (at

440Hz leakage current exceeds UL/VDE safety

spec.limit).

Current (nominal output at rated load):

-1UR:

1.0A a-c typ., 1.2A a-c max (120V a-c rms input);

0.5A a-c typ., 0.7A a-c max. (240V a-c rms input)

Options T, C, X and Y, all except 3.3V model:

0.7A rms max. (100-120 Va-c input);

0.4A rms max. (200-240 Va-c input).

Options T, C, X and Y, 3.3V model:

0.6A rms max. (100-120 Va-c input);

0.3A rms max. (200-240 Va-c input).

Initial Turn-on Surge: (one-half of first input cycle):

@120V a-c rms, 45A max.,

@240V a-c rms, 90A max.

Brownout Voltage: 85V a-c, 110V d-c

Switching Frequency: 120KHz typical, nominal load

STABILIZATION:

Source Effect: Range 95-132V a-c or

190-265V a-c, 0.2% typ.; 0.3% max.

Load Effect: Range 10%-100% load, 0.5% typ.; 1.5%

max.

Temperature Effect: Range 0oto 40oC, 0.5% typ.;

1.0% max.

Combined Effect: 0.9% typ.; 1.8% max. (includes

source, load, and temperature effects).

Time Effect: 0.2% typ.; 0.5% max. (1/2 hr-8 hr at

25oC).

RECOVERY CHARACTERISTICS: A step load

change from 50% to 100% produces less than +4% output

excursion. Recovery occurs to within +1% of the original

setting in <2 ms (load change tr or tfequal to or greater

than 50µsec).

START-UP TIME: 500 ms. maximum.

HOLDUP TIME:

-1UR: 20 ms. typ. (120V a-c), 15 ms. min (100V a-c);

Options T, C, X and Y, all except 3.3V and 28V mod-

els: 30ms typ. (20ms min.);

Options T, C, X and Y, 3.3V model:

55ms typ., 40ms min.;

Options T, C, X and Y, 28V model:

35ms typ., 25ms min.

DIELECTRIC STRENGTH:

Between input and output: 2KV a-c (3KV a-c for

Options T, C, X and Y) for one minute.

Between input and output with Y-capacitor removed:

3.75KV a-c for one minute.

Between input and case (ground): 2KV a-c for one

minute.

INSULATION RESISTANCE: Between input and

ground, output and ground, input and output;

100 Megohms min. (500V d-c).

LEAKAGE CURRENT

-1UR Models:

UL method, 120V a-c: 0.5 mA maximum;

VDE method, 240V a-c: 0.75 mA maximum.

Options T, C, X and Y:

120V a-c and 60 Hz (in conformance with Den-An):

0.28mA typ, 0.45mA max;

240V d-c and 60 Hz (in conformance with IEC 950

and UL1950)0.38mA typ, 0.6mA max.

SAFETY: UL 60950-1, 1st Edition, 2007-10-31; CSA

C22.2 No. 60950-1-03, 1st Edition, 2006-07; EN 60950.

Units are CE marked per the Low Voltage Directive (LVD),

73/23/EEC and 93/68/EEC. [The standards do not apply

with DC input operation]

EMI: Designed to meet FCC Class B (100-120V a-c) and

VDE 0871 Class B (220-240V a-c).

VIBRATION: (non-operating, one hour on each one of

the three axes): 5-10 Hz, 10 mm amplitude, 10-55

Hz, 2g acceleration.

SHOCK: (non-operating, one-half sinusoidal pulse, three

shocks to each axis): Acceleration: 20g, Duration:

11ms +5ms

OPERATING TEMPERATURE: See Figure 5.

STORAGE TEMPERATURE: -40oC to +75oC.

OPERATING AND STORAGE RELATIVE

HUMIDITY: up to 95% (wet bulb temp. <35oC non-con-

densing).