KFD 244.228W/060801 1

1.0 INTRODUCTION:

SCOPE OF MANUAL: This instruction brief contains information for the installation and operation of the

Kepco KFD 150 Watt DC to DC Converter. For further operating and service information for the KFD 150

Watt DC to DC Converter contact your Kepco Representative directly, or write to Kepco, Inc., 131-38 San-

ford Avenue, Flushing, New York 11352 U.S.A.

2.0 DESCRIPTION:

The Kepco KFD 150 Watt DC to DC Converter has a nominal 18-36 Vdc input and a 24 Volt DC output

nominal voltage. The DC to DC Converter is a low-dissipative stabilizer, using pulse-width modulation to

control the output. The unit features input/output isolation and remote ON/OFF. Remote ON/OFF is accom-

plished by an isolated TTL level signal that may use either mechanical or solid state closure. The output

voltage may be adjusted with a trimmer terminal located in the upper right hand corner of the unit (see Fig-

ure 3, top view). The unit is guaranteed for one year when operated within the specifications given herein.

3.0 ABSOLUTE MAXIMUM RATINGS:

The DC to DC Converter described in this manual is rated for continuous operation when used in an ambi-

ent temperature range of 0° to 71°C. Within this range the unit will operate according to the specifications

listed below, provided they are not subject to stress. The unit will function with degraded reliability and life

if operated at the extreme ends of the temperature range, at -40° to 0°C,or 71°C to 90°C. Specifications

Do Not Apply Throughout The Entire Operating Range (-40° To 90°C)

STRESSES IN EXCESS OF THE MAXIMUM RATINGS can cause permanent damage to the unit. THESE

are absolute stress ratings only. Functional operation of the unit is not implied at these or any other condi-

tions in excess of those in the following tables.

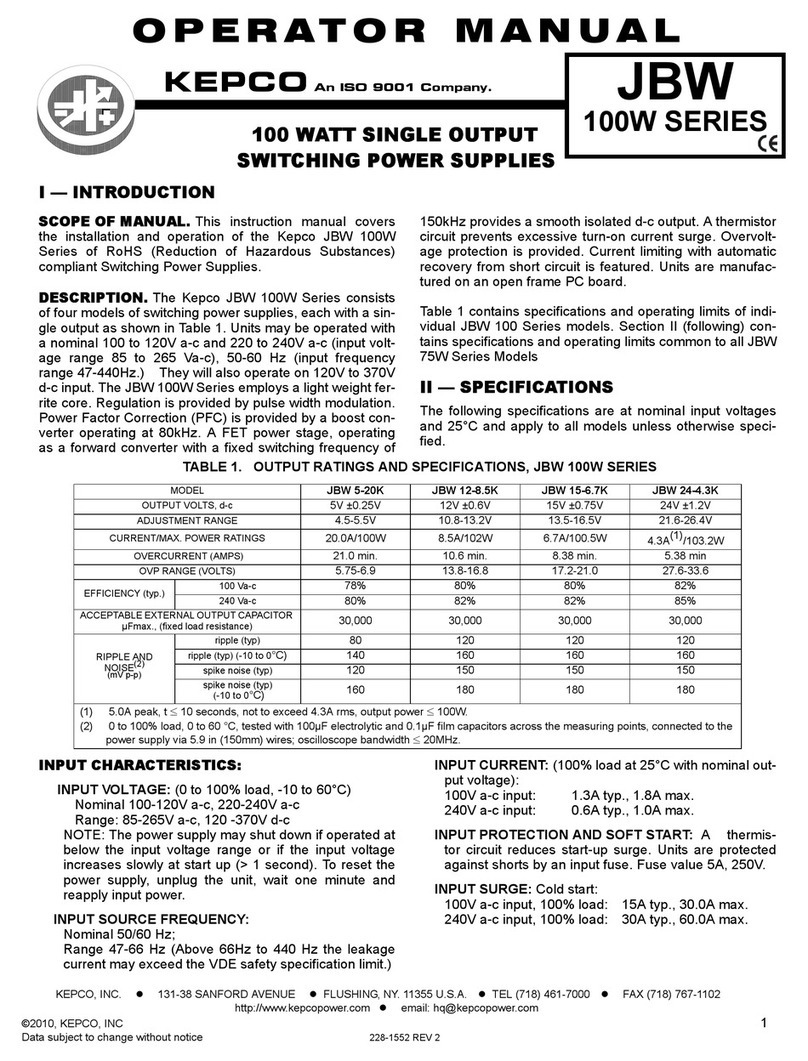

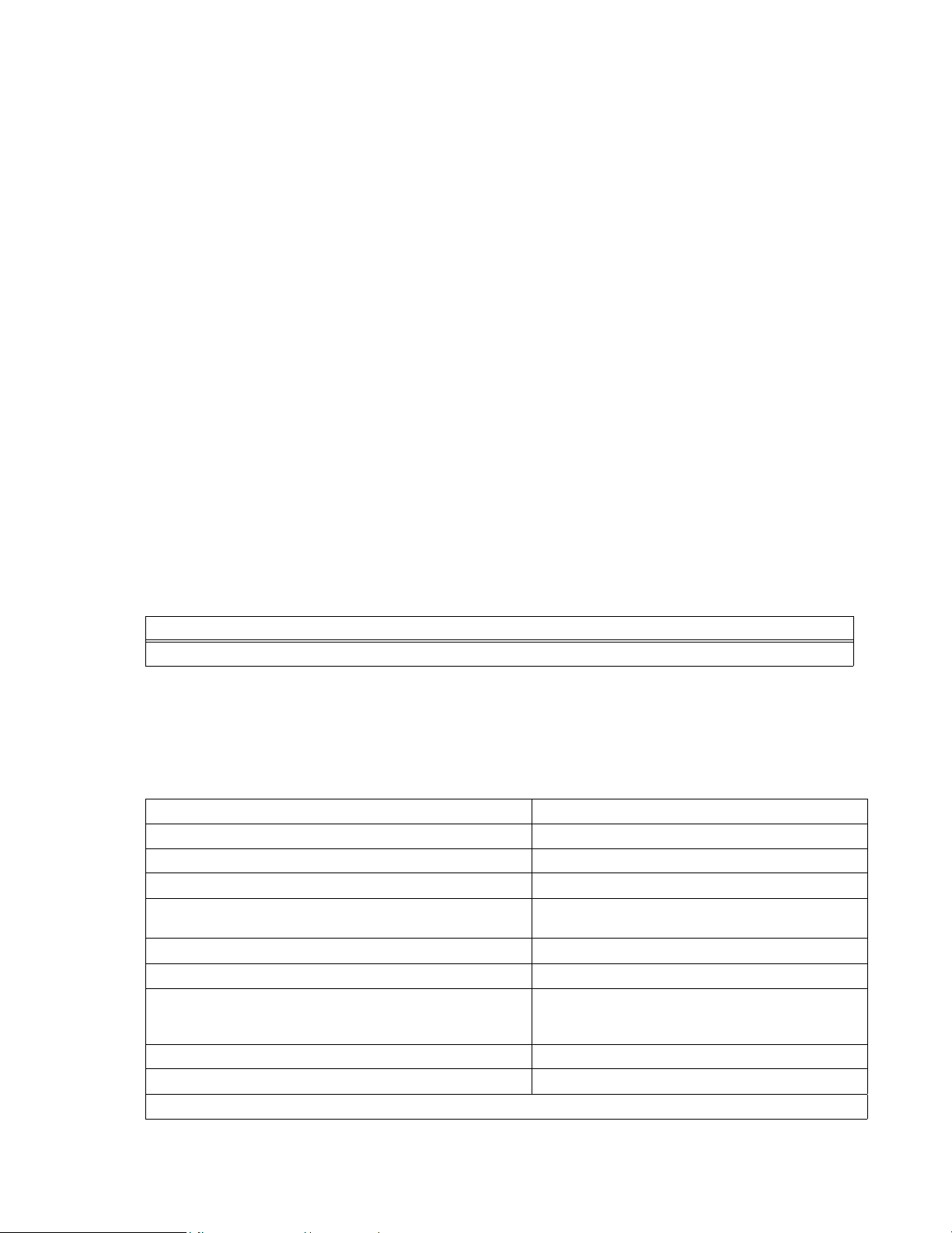

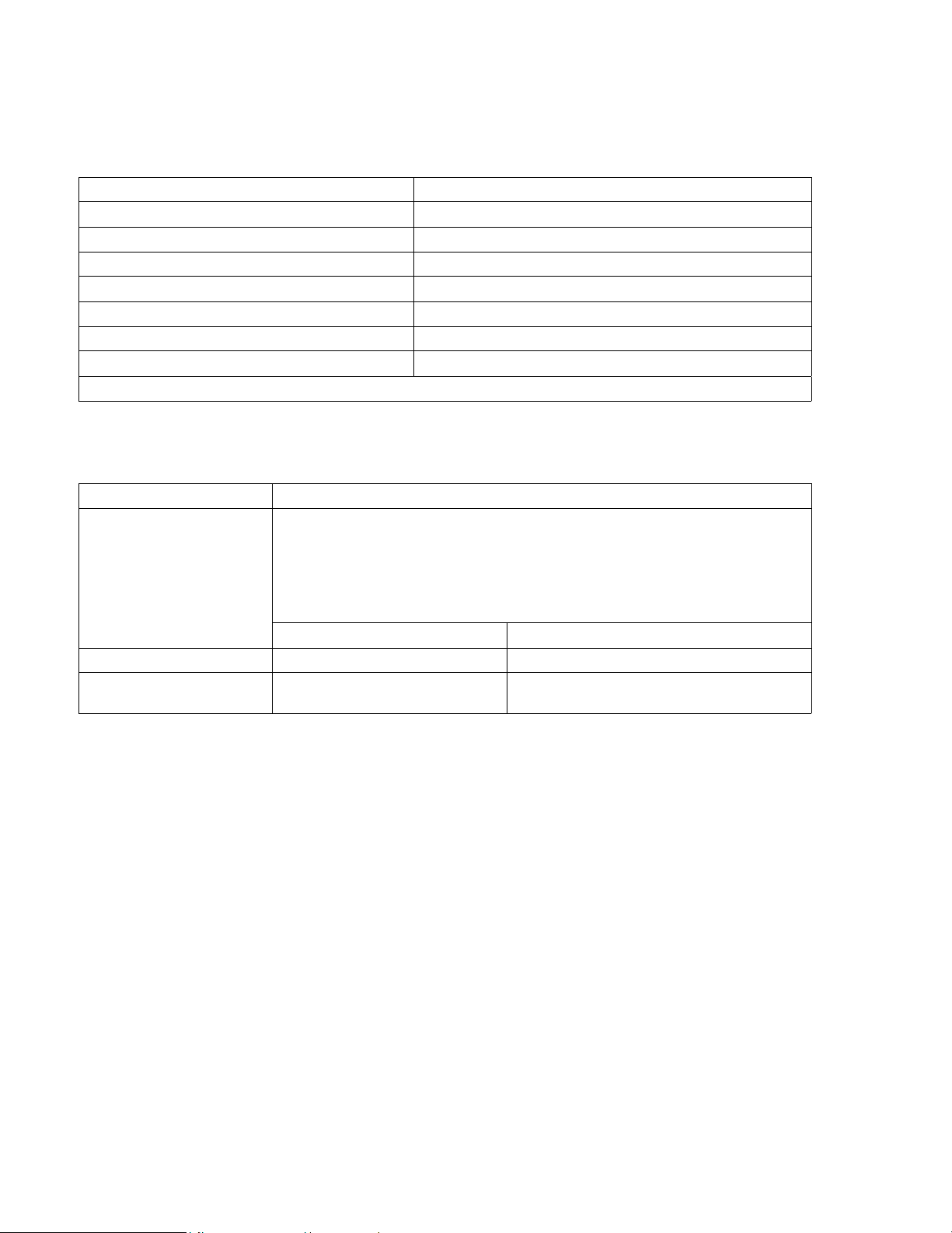

The following specifications apply to the power supply model listed below:

4.0 INPUT SPECIFICATIONS (SEE TABLE 1):

MODEL INPUT OUTPUT

KFD 24-4.2-28W 18-36 VOLTS DC 24 VDC 4.2A

TABLE 1. INPUT SPECIFICATIONS

Parameter Description

Nominal Input Voltage 28 Vdc

Input Voltage Range 18-36 Vdc

Input Current Maximum* 8A (VI=0 to 36 Volts)

Efficiency: VI=48 Volts, Io= Io, max.;TA=20°C

See Figure 1

90% typical

86 minimum

Switching Frequency 100KHz

Circuit Type Forward Converter

Input Reflected Ripple Current

(peak to peak,5Hz to 20 MHz, 12µH source impedance,

TA=25°C, see Figure 2)

20 mA peak to Peak

Input Ripple Rejection (120Hz) 60 dB typical

Inrush Current (I2t) 2.0 A2s maximum

*THE KFD MODULE IS NOT INTERNALLY FUSED, AN INPUT LINE FUSE MUST ALWAYS BE USED