080515 228-1744 REV 3 7

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

3.4 VERIFICATION MEASUREMENTS

Prior to shipping, the Transition Circuit has been tested in a BOP 1KW. The following measurements ensure that

the Transition circuit has been installed correctly, or for debugging. Table 2 lists the test equipment needed to per-

form these measurements.

3.4.1 A7A3R5 Measurement

1. With the unit turned off, connect a DVM (set for DC voltage measurements) to Transition Circuit A7A3R5 (end

closest to A7A3J1; see Figure 1), referenced to TP2.

2. Install the power cord and connect the BOP to source power.

3. With no load connected, turn on the unit, then set the BOP to voltage mode, enable the output and program

the output voltage to positive full scale (6V).

4. Set the current limit to the full scale value (125A).

5. Verify that the DVM measures –10V ±0.5V.

6. Set the output voltage to negative full scale and verify that the DVM measures +10V ±0.5V. Turn off the unit.

3.4.2 A7A3TP3 Measurement

1. With the unit turned off, connect the DVM to Transition Circuit A7A3TP3, referenced to TP2.

2. Install a short-circuit across the BOP output.

3. Turn on the unit, then set the BOP to current mode, enable the output and program the output current to posi-

tive full scale (125A).

4. Set the voltage limit to the full scale value (6V).

5. Verify that the DVM measures +10V ±0.1V.

6. Set the output current to negative full scale. Verify the DVM measures –10V ±0.1V, then turn off the unit

3.4.3 A7A3R17 Measurement

1. With the unit turned off, connect the DVM across A7A3R17 (reference lead connected to the resistor end near-

est to A7A3J4).

2. Disconnect the short-circuit from the output and connect a resistive load RL (see Table 2) across the output.

Turn on the unit, set voltage mode, enable the output and program the output voltage to positive full scale. Set

the current limit to the full scale value. The DVM should measure 0V ±10mV. Turn off the unit.

3. With the unit turned off, leave the DVM across A7A3R17 and connect a scope probe to A7A3D3 anode (refer-

enced to the end of resistor A7A3R17 nearest to A7A3J4). Set the scope for 1V/div, 5ms/div, normal triggering

(positive edge, single).

4. Disconnect the load from the output and connect a variable power supply PS (see Table 2) to the BOP with PS

positive terminal to BOP OUT terminal and PS negative terminal to BOP COM terminal. Set the PS for to the

nominal output voltage of the BOP (6V), and set PS current limit value to minimum (zero).

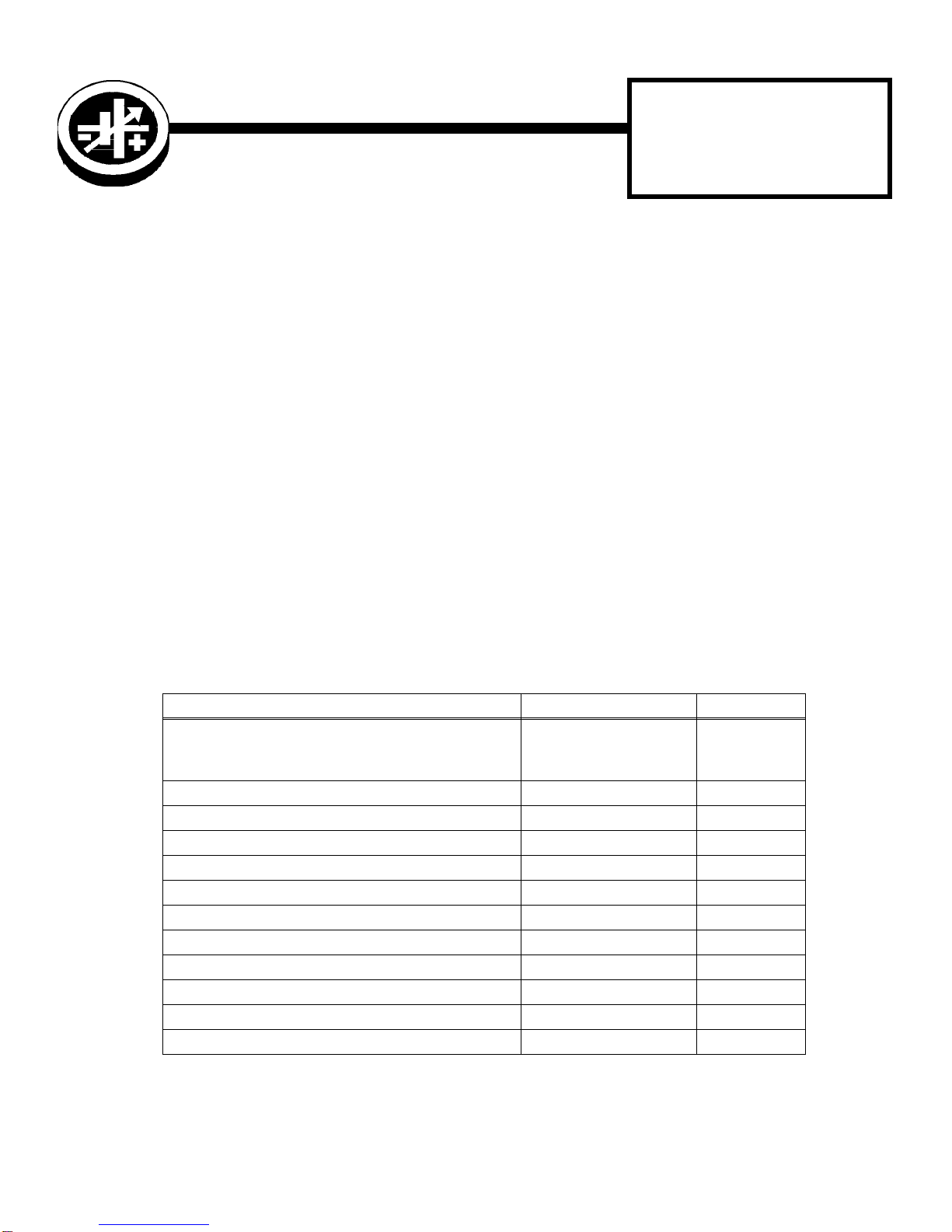

TABLE 2. TEST EQUIPMENT REQUIRED

Test Equipment Requirement

Digital Voltmeter (DVM) Voltage measurements (d-c)

Resistive Load (RL) Value (Ohms) = 200 x Nominal Output Voltage / Nominal Output Current

(RL = 10 Ohms, 10W).

Variable Power Supply (PS) Unipolar, adjustable, able to deliver Nominal Output Voltage of 6V with an adjust-

able current limit having a maximum value of at least 20A.