BOP-H 020498 i

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope of Manual......................................................................................................................................... 1-1

1.2 Options ....................................................................................................................................................... 1-1

1.2.1 Primary Options....................................................................................................................................... 1-1

1.2.1.1 Display/Front Panel Control (D Option):............................................................................................. 1-1

1.2.1.2 Digital Remote Control (G Option, e Option)...................................................................................... 1-1

1.2.2 Secondary Options.................................................................................................................................. 1-2

1.2.3 Inductive Load Optimization (L Option):.................................................................................................. 1-2

1.2.4 Capacitive Load Optimization (C Option):............................................................................................... 1-2

1.2.5 Inductive Load Optimization (LC Option): ............................................................................................... 1-2

1.2.6 Master/Slave (S Option):......................................................................................................................... 1-2

1.2.7 Relay - Crowbar (R Option):.................................................................................................................... 1-2

1.2.8 DC Current Transformer (DCCT) (Z Option):.......................................................................................... 1-3

1.3 General Description.................................................................................................................................... 1-3

1.4 Electrical Specifications, General............................................................................................................... 1-4

1.5 Miscellaneous Features.............................................................................................................................. 1-12

1.5.1 Output Range.......................................................................................................................................... 1-12

1.5.2 Programming Features............................................................................................................................ 1-12

1.5.3 ON-OFF Feature..................................................................................................................................... 1-13

1.5.4 Load Reactance...................................................................................................................................... 1-13

1.5.4.1 Driving an Inductive Load in Current Mode........................................................................................ 1-13

1.5.4.2 Driving a Capacitive Load in Voltage Mode ....................................................................................... 1-14

1.5.5 Remote Turn-off...................................................................................................................................... 1-14

1.5.6 Circuit Breaker Shutdown Prevention ..................................................................................................... 1-15

1.5.7 References.............................................................................................................................................. 1-15

1.5.8 Series Or Parallel Operation ................................................................................................................... 1-15

1.5.9 Voltage Control Channel......................................................................................................................... 1-15

1.5.10 External Voltage Monitor......................................................................................................................... 1-16

1.5.11 External Current Monitor......................................................................................................................... 1-16

1.5.12 Mode Control........................................................................................................................................... 1-17

1.5.13 Current Control Channel ......................................................................................................................... 1-17

1.5.14 Bounding................................................................................................................................................. 1-17

1.5.15 Front Panel Status Indications ................................................................................................................ 1-18

1.5.15.1 POWER (G)/FAULT (R)/LIMIT (O) indicator...................................................................................... 1-18

1.5.15.2 OUTPUT ON indicator ....................................................................................................................... 1-18

1.5.15.3 MASTER (G)/SLAVE (Y) indicator..................................................................................................... 1-18

1.5.15.4 DIG ON/REM ON-OFF indicator........................................................................................................ 1-18

1.5.16 Rear Panel Status Indications................................................................................................................. 1-19

1.5.17 Standards................................................................................................................................................ 1-19

1.6 Mechanical Specifications .......................................................................................................................... 1-19

1.7 Equipment Supplied.................................................................................................................................... 1-19

1.8 Accessories ................................................................................................................................................ 1-20

1.9 Safety.......................................................................................................................................................... 1-21

SECTION 2 - INSTALLATION

2.1 Unpacking and Inspection. ......................................................................................................................... 2-1

2.2 Terminations, Controls and Indicators........................................................................................................ 2-1

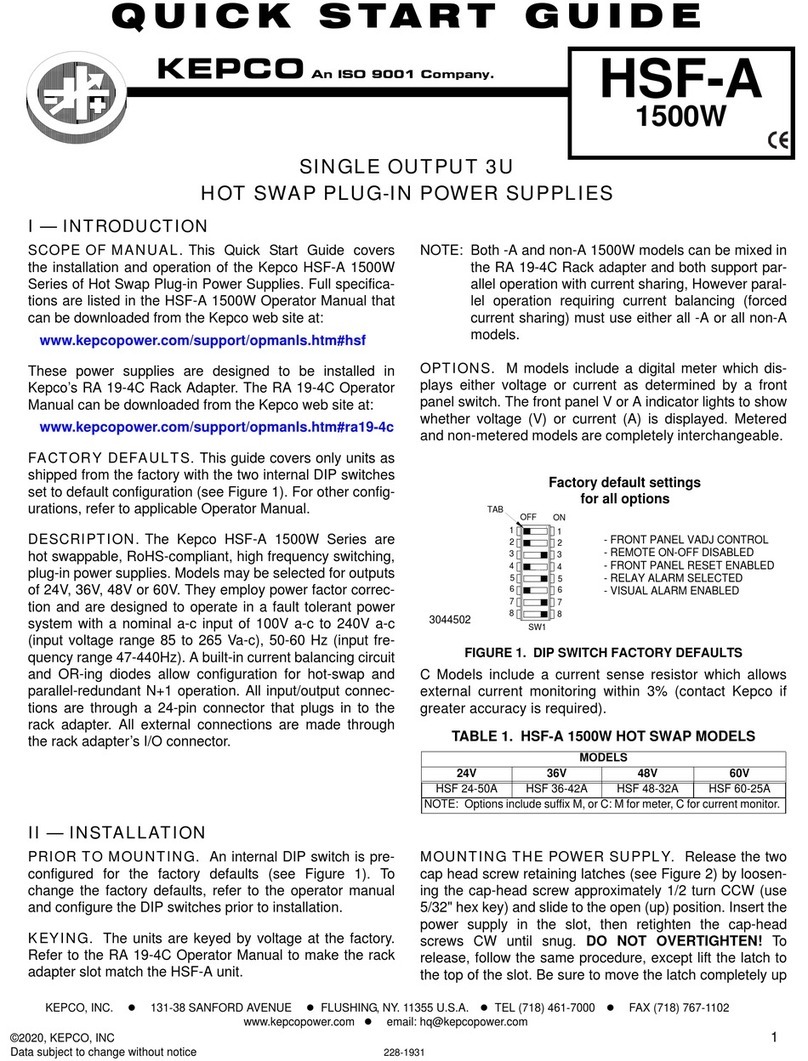

2.3 Factory Defaults.......................................................................................................................................... 2-13

2.4 A-C Input Requirements ............................................................................................................................. 2-13

2.5 Cooling........................................................................................................................................................ 2-13

2.6 Preliminary Checkout.................................................................................................................................. 2-13

2.7 Installation................................................................................................................................................... 2-19

2.7.1 Slide Installation...................................................................................................................................... 2-19

2.8 Load Connection......................................................................................................................................... 2-21

2.8.1 Load Connection, Local Sensing............................................................................................................. 2-21

2.8.2 Load Connection, Remote Sensing......................................................................................................... 2-21