8

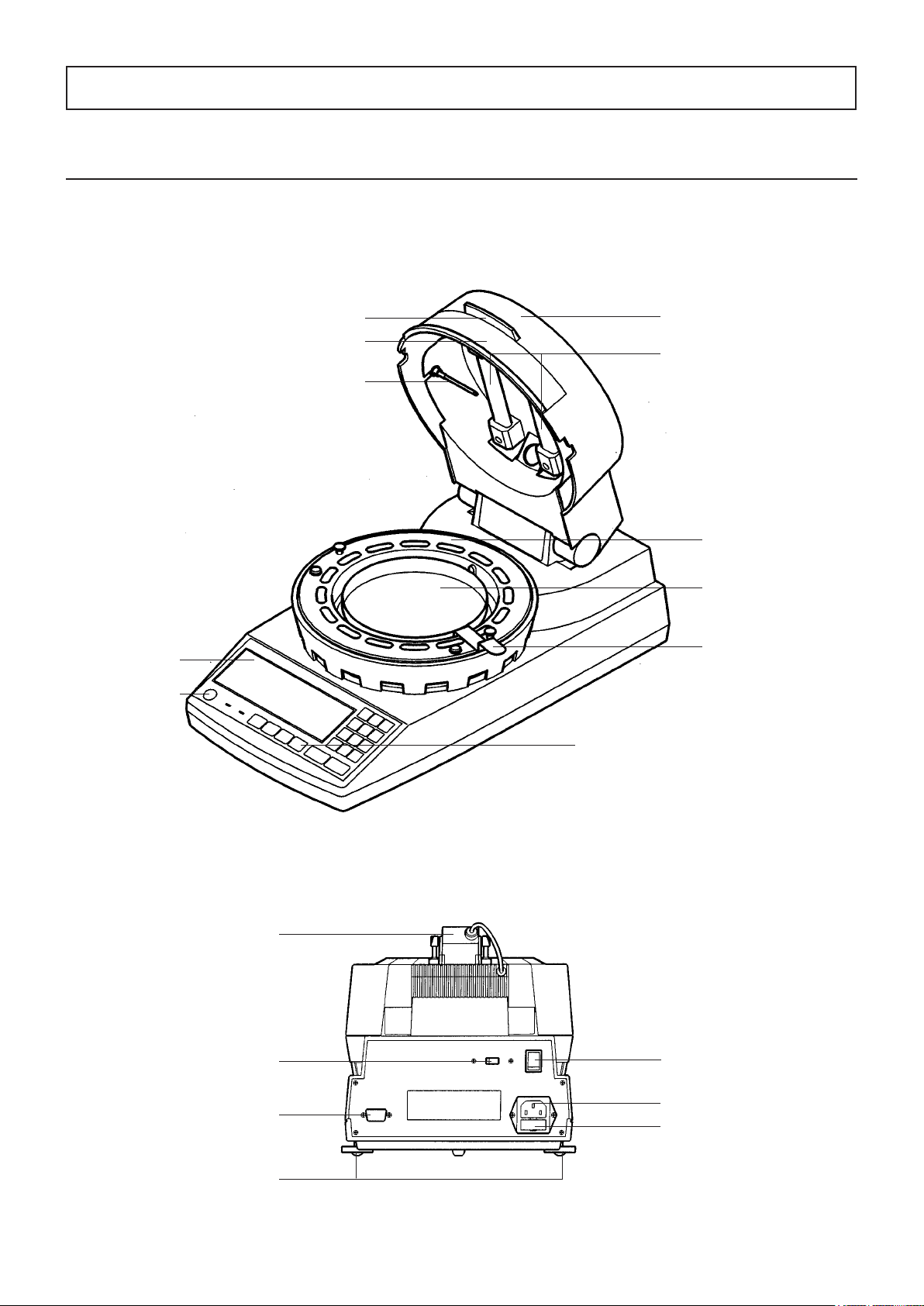

■PrinciplesofOperation

This unit determines the moisture and solid contents of samples by heating them using infrared

illumination and measuring changes in mass due to evaporation. This is referred to as the loss on

drying method and is the simplest method for determining moisture content and thus mandated by

many public regulations related to measurement standards.

■Features

lEquipped with a radiation thermometer

In addition to temperature measurement by a conventional thermistor (T1 measurement), it is equipped with a radiation

thermometer that can directly measure the surface temperature of a sample. (T2 measurement*1) This radiation

thermometer permits drying of a sample in a short time with good reproducibility without burning the sample.

lEquipped with a ten-key pad

The ten-key pad is used to enter numbers and letters simplifying entry.

lUniBloc sensor

The core of the scale is formed by a single-unit aluminum UniBloc*2 weight sensor which provides excellent

responsiveness, temperature characteristics, and shock resistance. This UniBloc*1 sensor ensures excellent reliability

in moisture content measurements even over extended use.

lNew Auto Taring mechanism

The FD-800 comes with an internal Auto Taring mechanism which makes it possible to perform reset correction while

performing measurements, thus eliminating drift of the scale even when performing measurements over long periods

of time and making it possible to obtain extremely reliable measurements.

lMid-infrared quartz heating lamp

The FD-800 uses a mid-infrared quartz heating lamp (with a central wavelength of 2.6 μm). This heater provides

excellent drying efciency over a wide range of different types of sample, makes it difcult for differences to occur as

a result of the colors of different samples, and eliminates the overheating of sample surfaces, thus making it possible

to obtain ideal drying conditions.

What‘s more, this heating lamp also provides a long service life 5~10 times greater (20,000 to 30,000 hours*3) than

older infrared or halogen lamps.

lA wide selection of measuring modes

The FD-800 provides a wide selection of measuring modes (automatic halting mode, timed halting mode, high-speed

drying mode, low-speed drying mode, stepped drying mode, and predictive measuring mode) which makes it possible

to perform measurements under the drying conditions most appropriate to the drying characteristics of the sample

being measured.

lThe ability to store measuring conditions

The FD-800 provides 100 measuring conditions storage areas which may be used to store sets of measuring condi-

tions to be used for different types of materials, thus reducing the amount of time involved in specifying settings before

performing measurements.

lData memory

The FD-800 is able to store up to 100 sets of measurement data in memory, thus making it possible to output large

batches of data all at one time.

lScale (and the radiation thermometer) can be calibrated

Scales (and the radiation thermometer) can be calibrated. During calibration, output can be printed in response to the

demand for GLP, GMP, ISO.

*1 Patent pending.

*2 UniBlock is a product name of the Shimadzu Corporation.

*3 Indicates average life of heater but does not guarantee actual life time.

■Applications(i.e.,materialswhichcanbemeasured)

l Materials for which water is the only main component which evaporates as a result of heating

l Materials for which no dangerous chemical reactions or other changes occur as a result of heating

* Measurements can be performed using virtually any material meeting these conditions.

2. Description of Features and Principles of Operation