CONTENTS

1. Safety Precautions ...........................................................................................................................4

2. Measuring Principle and Features..................................................................................................6

■ Measuring principle ....................................................................................................................6

■ Features .....................................................................................................................................6

■ Measurable objects ....................................................................................................................6

3. Specications ...................................................................................................................................7

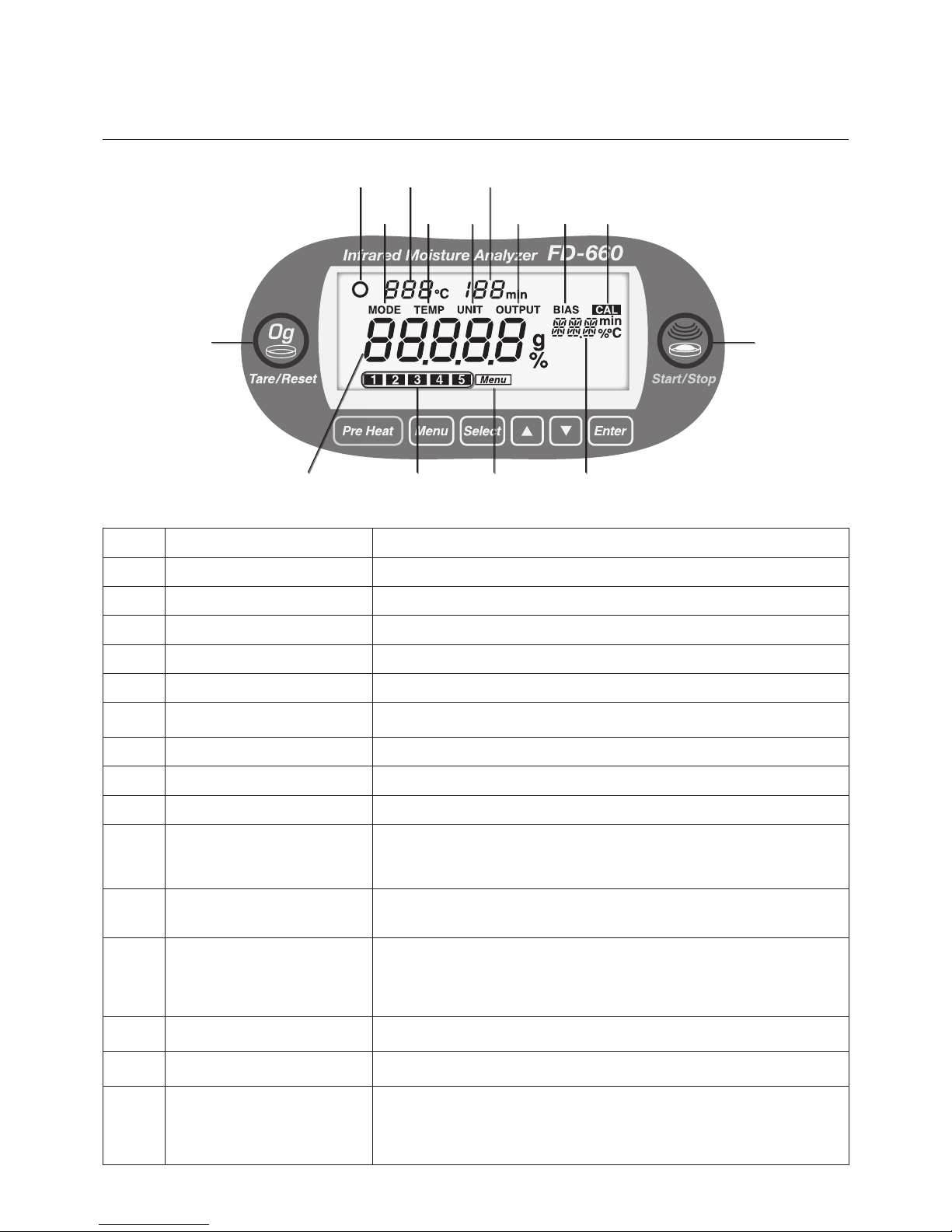

4. Part Names........................................................................................................................................8

4-1. Names of Main Unit Parts ......................................................................................................8

4-2. Accessories ............................................................................................................................9

4-3. Display .................................................................................................................................10

4-4. Control Panel Functions ....................................................................................................... 11

5. Assembly and Installation .............................................................................................................12

■ How to manually specify the power supply voltage .................................................................14

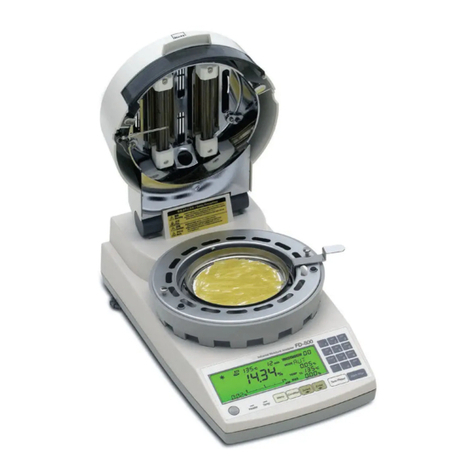

6. Measurement Procedure................................................................................................................15

■ Tips on how to ensure accurate measurements ......................................................................18

● First measurement ..........................................................................................................18

● For multiple measurements in succession ......................................................................19

● How to use sample dish and aluminium foil sheet ..........................................................19

● Measurement of powdered, particulate, and viscous samples .......................................19

● Measurement of liquid sample ........................................................................................19

● Measurement of large particulate sample .......................................................................19

● Removal of soil, sample gas, and others ........................................................................19

● Deodorizing windshield case ..........................................................................................19

7. Specifying Measuring Settings .....................................................................................................20

8. Menu Settings.................................................................................................................................22

8-1. Setting for MODE (measuring mode) ...................................................................................22

● Setting for AUTO (automatic) mode ................................................................................22

● Setting for TIME (timed) mode ........................................................................................24

8-2. Setting for TEMP (drying temperature) ................................................................................26

8-3. Selection of UNIT (measurement standard and minimum display digit) ..............................28

8-4. Selection of OUTPUT (output format) ..................................................................................30

■ Outputting Past Measurement Data ...............................................................................32

■ Sample Printer Output ....................................................................................................32

■ Computer Interface .........................................................................................................32

■ Setting UP and Transmitting Data ..................................................................................32

■ Computer Output Format ................................................................................................33

8-5. Setting for BIAS (offset value) ..............................................................................................34

8-6. CAL (scale calibration) .........................................................................................................36

9. Maintenance....................................................................................................................................40

9-1. How to Perform Maintenance ..............................................................................................40

9-2. Fuse Replacement ...............................................................................................................40

9-3. Heater Replacement ............................................................................................................41

10. Error Display.................................................................................................................................42