THE KETT TOOL COMPANY 5055 Madison Road, Cincinnati, Ohio 45227

(513) 271-0333 fax (513) 271-5318 www.kett-tool.com

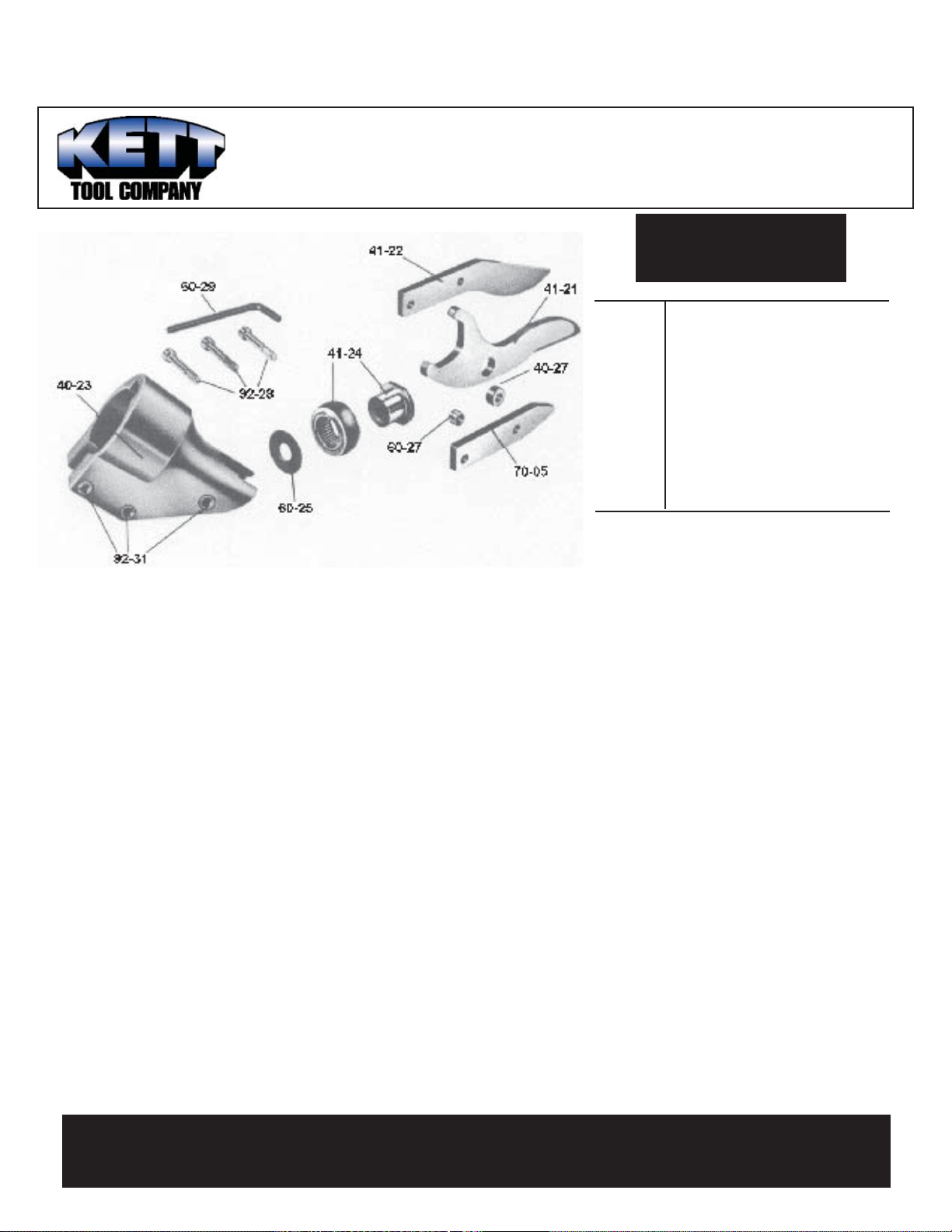

INSTRUCTIONS FOR THE CARE OF

THE KETT 41-20 SHEAR HEAD

CAUTION

Disconnect Power Unit

Before Servicing Tool

PARTS LIST

41-21 Center Blade

40-23 Shear Housing

41-24 Eccentric Bearing Assembly

40-27 Spacer Bushing

92-28 Cap Screw (3)

92-31 Knurled Insert (3)

41-22 Side Knife

70-05 Side Spacer

60-25 Thin Washer, Large

60-27 Spacer Bushing

60-29 (150-4) Allen Wrench

DISASSEMBLY: To remove the shear head from the

motor loosen three cap screws (92-28). Remove shear

head from motor by pulling head firmly forward. Slight

tapping with a mallet may be required if head does not

slide off easily.

To remove cutter blades from shear head remove

three cap screws (92-28) from shear housing (40-23).

Be careful not to lose rear spacer bushing (60-27) when

removing the middle cap screw. Remove center blade

(41-21) from shear housing by tapping blade gently rear-

ward. Be careful not to lose spacer bushing (40-27) from

hole in center blade. Side knife (41-22) and side spacer

(70-05) will now drop out of the shear housing.

To remove eccentric bearing assembly (41-24)

from shaft use an appropriate wrench to loosen eccen-

tric nut by turning counter clockwise.

ASSEMBLY: To install eccentric bearing assembly (41-

24) onto shaft, make sure the large thin washer (60-25)

is first inserted over the shaft. Screw eccentric bear-

ing assembly on to shaft and tighten with appropriate

wrench. Lubricate bearing with a good grade of bearing

grease.

To install cutter blades into shear housing (40-

23) place the side knife (41-22) and side side spacer

(70-05) into position in the shear housing (40-23). Insert

center cap screw (92-28) through the 41-21 and 70-05

with rear spacer bushing (60-27) between them and

start cap screw into thread just enough to hold blades in

place. DO NOT TIGHTEN. Insert spacer bushing (40-

27) into hole in center blade (41-21) and lubricate with

Molybdenum Disulfide grease (264-2) or equivalent.

Install center blade into shear housing by tapping blade

gently forward using a drift to line up hole in center blade

with forward holes in housing. Insert and tighten forward

cap screw (92-28) making sure spacer bushing (40-27)

in center blade stays in position. Apply Molybdenum

Disulfide grease (264-2) or equivalent to clevis or yoke

in center blade where it rides on the eccentric bearing

assembly. Insert rear cap screw (92-28) into shear hous-

ing, but do not completely tighten.

To install shear head assembly onto drive motor

make sure all cap screws (92-28) are loosened about

three or four complete turns. Spread shear housing

(40-23) slightly using a spreader (drift) near the rear cap

screw (92-28). Place shear head onto unit, tap side knife

rearward as far as it will go, and tighten cap screws to

40-45 inch pounds. It may be necessary to gently tap

the shear head into place if it does not readily slip onto

the nose of the power unit.

WARNING: THE KETT TOOL CO. CANNOT ASSUME RESPONSIBLITY FOR DAMAGE TO OR

MALFUNCTION OF A KETT SHEAR HEAD USED IN COMBINATION WITH ANY DRILL OTHER

THAN THOSE REGULARLY SUPPLIED BY US.

40-61 Not Shown

Adapter (1 3/8”-20 LH thread) fits

253-58 power unit on KD-441 power

shear.