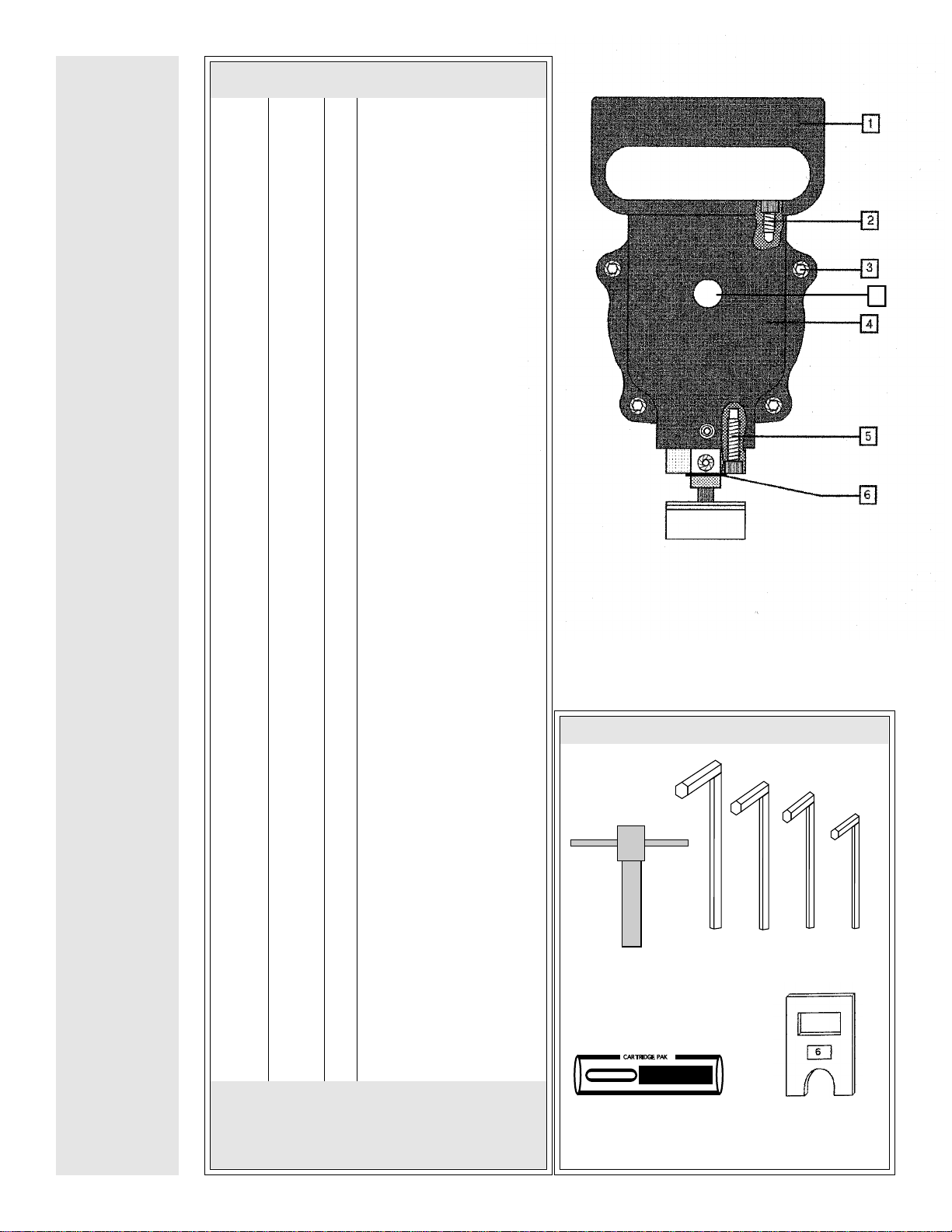

ACCESSORIES

Item No. Part No. Qty. DESCRIPTION

1 N7065 1 Handle

2 N7018 4 Screw, Handle

3 N7057 4 Screw, Body

4 N7037 1 Nose Housing

5 N7055 4 Screw, Die Holder

6 N7035 4 Stripper Shim

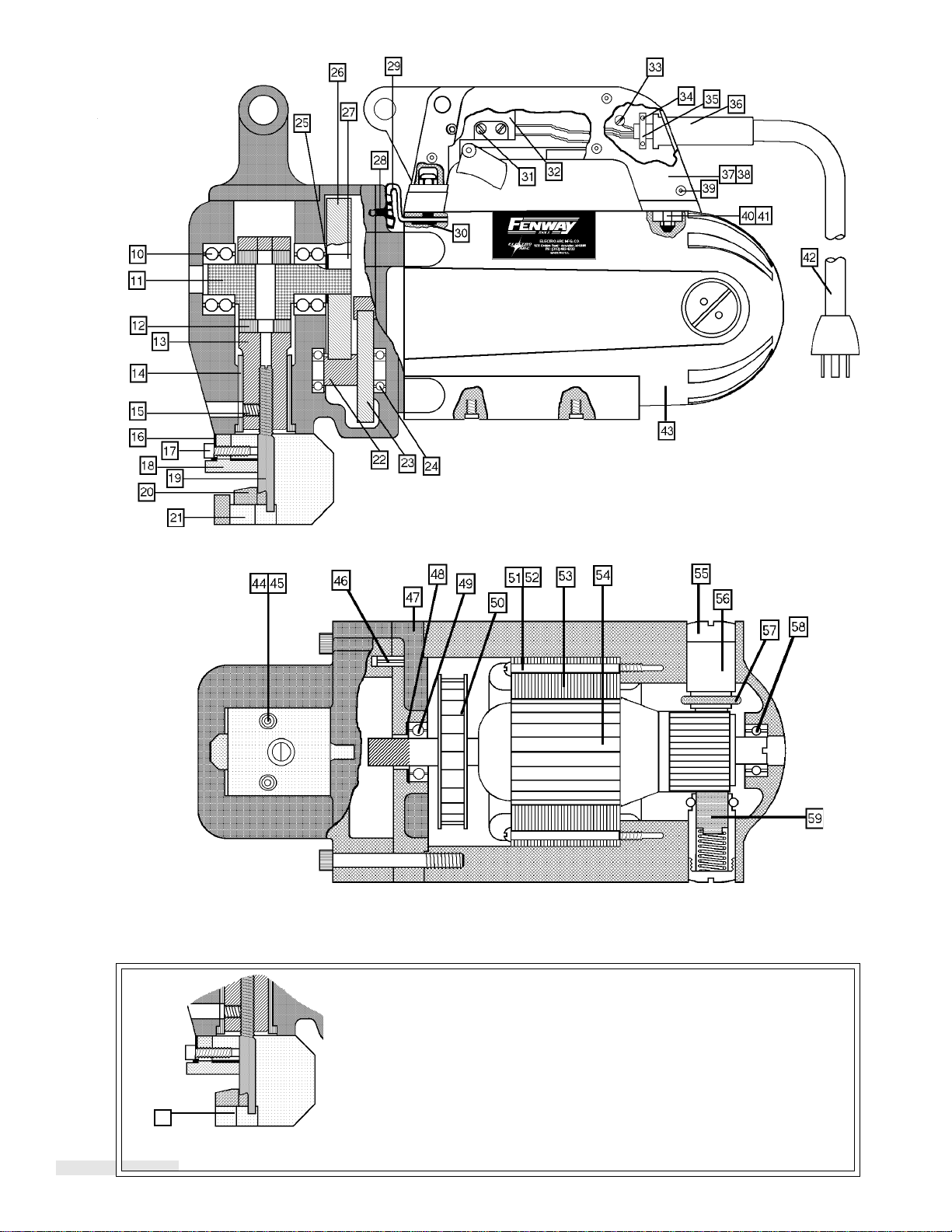

10 N7040 2 Bearing, Eccentric Shaft

11 N7038 1 Eccentric Shaft

12 N7039 1 Slider Block

13 N7036 1 Plunger

15 N5027 1 Screw, Punch Locking

16 N7032 1 Stripper Clamp Plate

17 N7031 1 Screw, Stripper

18 N7030 1 Stripper

N7030-1 1 Stripper, SHN-II

19 N7033 1 Punch

N7034 1 Punch, HSS

20 N7028 1 Die

N7029 1 Die, HSS

21 N7063 1 Die Holder

22 N7052 1 Pinion Gear Shaft

23 N7051 1 Small Gear

24 N5054 2 Bearing

25 N7046 1 Eccentric Shaft Spacer

26 N7041 1 Large Gear

27 N7045 1 Key

28 N7049 1 Screw, Ground

29 N3006 1 Ground Wire Assy.

30 N3007 1 Ground Wire Retainer

31 N3008 2 Screw, Switch Mounting

32 1 Switch

33 N3011 1 Screw, Ground

34 N3012 2 Screw, Cord Clamp

35 N3013 1 Cord Clamp

36 N3014 1 Strain Relief

37 N3002 1 Handle

38 N3003 1 Handle Cover

39 N3004 5 Handle Cover Screw

40 N3017 2 Handle Locking Screw

41 N3016 2 Self Lock Nut for Handle

42 N7015 1 Cord With Plug

43 N7001 1 Motor Housing*

AN7001 1 Complete Motor Housing Assy.**

44 N7058 2 Die Screw

45 N3050 2 Lock Washer

46 N7054 2 Dowel Pin

47 N7042 1 Gear Housing

48 N5024 1 Load Spring

49 N7048 1 Front Armature Bearing

50 N7068 1 Fan

51 N7047 2 Field Screw

52 N2050 2 Lock Washer

53 N7019 1 Motor Field (110V)

N7020 1 Motor Field, 220V

54 N7021 1 Armature (110V)

N7022 1 Armature, 220V

55 N5032 2 Brush Holder Cap

56 N7026 2 Brush Holder(not replaceable)

57 N5071 2 Field Spring

58 N3048 1 Rear Armature Bearing

59 N7044 2 Carbon Brush

60 N3059 1 Button Plug

S

U

P

E

R

P

A

R

T

S

L

I

S

T

KETT / Fenway Super Nibbler 4

PARTS LIST

* Includes: N7026

** Includes: N7001, N3002, N3003, N3004, N3016, N3017,

N3012, N3013, N5032, N7026

Figure 1

CARTRIDGE PAK

KETT

LUBRICANT

(1//4) (3/16) (5/32) (3/32)

N7059 N0106 N0105 N0102 N0101

"T" WRENCH

N0109 N7035

SHIM

60

N3009