OPERATION

Avoid Accidental Starting

Don’t carry plugged-in tool with finger on switch. Be sure switch is OFF when plugging in. Use of any accessory with this power unit might increase the hazard. The

tool should be used only for the purpose for which it is designed.

Plug

THE POLARIZED PLUG IS A SAFETY FEATURE. This tool is equipped with a polarized two wire AC line plug. The two wire polarized plug (having one blade wider

than the other) will fit into the power outlet only one way. DO NOT DEFEAT THE SAFETY PURPOSE OF THE POLARIZED PLUG, by tampering with it. If the plug

does not fit you should still be unable to fully insert the plug into the socket, you may find that a proper outlet is needed to meet today’s electrical standards.An

electrician will replace your outlet safely.

Extension Cords

Always check the extension cord and repair or replace if damaged.

Outdoor Use Extension Cords

When tool is used outdoors, use only extension cords marked W-Aor W.

Stay Alert

Watch what you are doing, use common sense when operating a power tool. Do not use tool while tired or under the influence of drugs, alcohol or medication.

Check Damaged Parts

Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment if moving parts, binding or moving parts, breakage of parts, mounting, and any other conditions that may affect its operation.Aguard

or other part that is damaged should be properly repaired or replaced by an authorized service center unless otherwise indicated elsewhere in this instruction man-

ual. Have defective switches replaced by authorized service center. Do not use tool if switch does not turn it on or off. DO NOT OPERATE power tools in explosive

atmospheres such as in the presence of flammable liquids, gases, or dust. Motors in these tools normally spark and sparks can possibly ignite fumes.

Read all instruction.

Save these instructions.

FUNCTIONAL DESCRIPTION

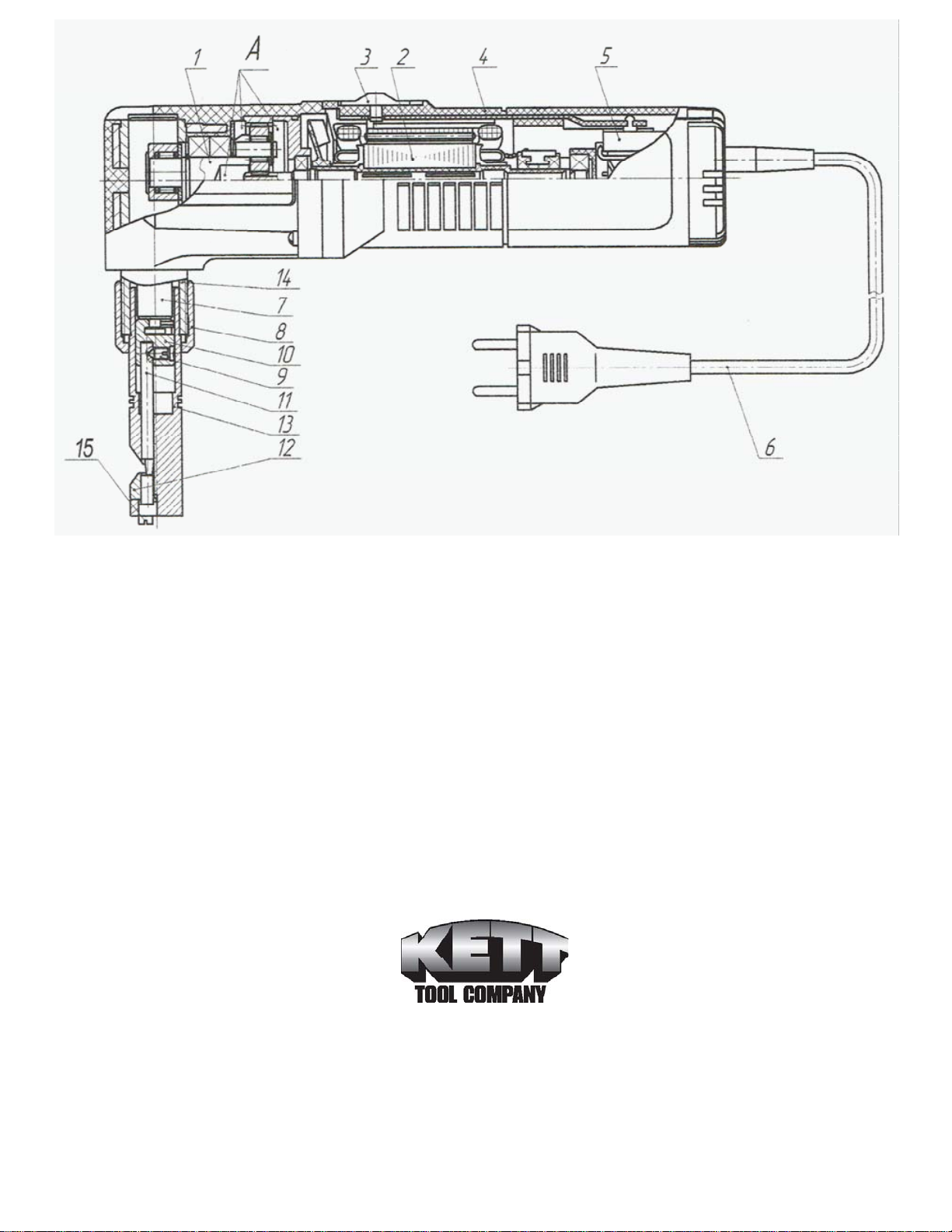

Pre-starting procedure (Fig. 1)

• Check all fasteners to be sure they are tight.

• Check the trigger (3) to see that it is moving freely.

Switching on and off (Fig.1)

• Move the trigger (3) forward to turn the nibbler ON; moving the trigger back turns the nibbler OFF.

• Red dot on the housing (4) near the trigger (3) shows that switch is in ON position.

Test run

Perform a no-load test run of 10-15 seconds prior to starting cutting.

Operating procedure

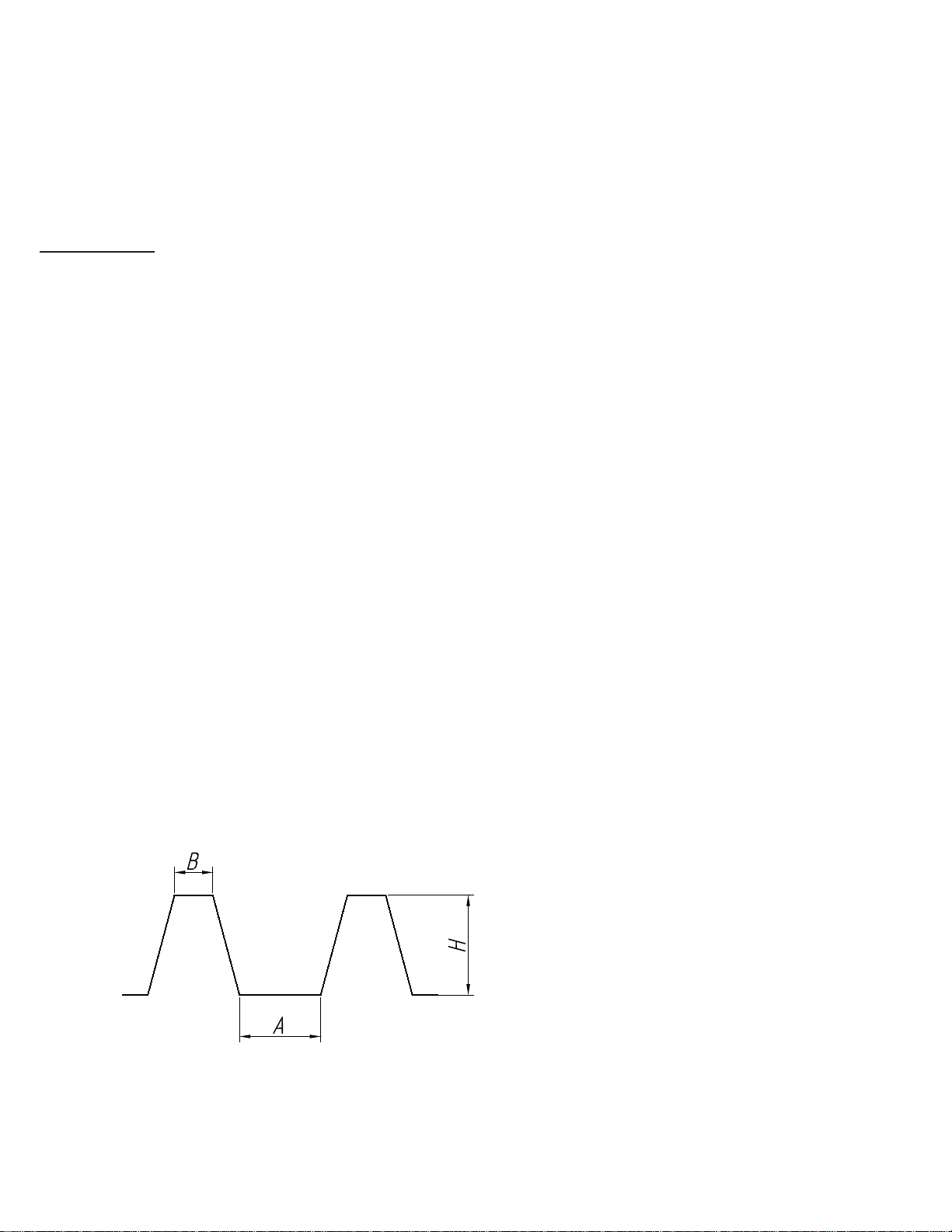

• With the nibbler ‘ON’ insert it into the cutting sheet at the lower V-shaped slot between the die holder (13) and the die (12).

• When cutting, hold the tool so, that the punch (11) is at a right angle to the sheet plane.

• Move the nibbler carefully without putting to much pressure in direction of the cut.

• The temperature of the gear box (1) and the front motor housing (4) should not exceed accordingly 108ºF and 90ºF above ambient. The cooling holes

should be always clean and un-obstructed.

• For cutting within the sheet, it is necessary to drill a pilot hole with the minimum diameter of about 7/8 of an inc, large enough to insert the die

holder (13).

• Periodically, before beginning to work and after cutting about 5-6 feet of material, it is necessary to lubricate the punch (11) and the die (12).

Dip the end of the die holder into light oil 5/8” to 3/4” deep. Also, lightly lubricate the top surface of the metal sheet along the cutting line.

• It is recommended to take a break to cool the gear box to ambient temperature after cutting of every 12 to 15 feet in order to extend the tool life.

• Periodically lubricate the plunger (7) and the punch holder (10).

Punch and die replacement

When the cutting edges of the punch and/or die become worn, it is necessary to replace them. When replacing parts, clean all chips from the tool.

To replace the punch:

• Unfasten nut (8) and take the die holder (13) off.

• Place plunger (7) and punch (11) with the punch holder (10) to the bottom stroke by rotating the fan through holes in the gear box.

• Take the punch, the punch holder and plunger off.

• Unfasten the lock screw (9).

• Replace the punch.

• Fasten the punch lock screw.

• Re-assemble the tool.

• After replacing the punch, check the tool at no-load speed for 30-60 seconds. The die holder should not get warm.