5 Dual Zone Digital Location Control Unit Installation and Operation Manual

Regulatory information

The control unit is approved to UL864 (tenthedition).

Installations that are required to comply with UL must be installed in accordance

with NFPA 70, NFPA 72, and NEC 760 (National Electric Code).

Non-UL installations must be installed in accordance with the relevant local

standards and AHJ’s (Authority Having Jurisdiction).

Description

Alarmline II Digital Sensor Cable has an insulation designed to soften at a

particular temperature (the cable alarm temperature) – when the cable reaches

this temperature, it short circuits and activates an alarm condition.

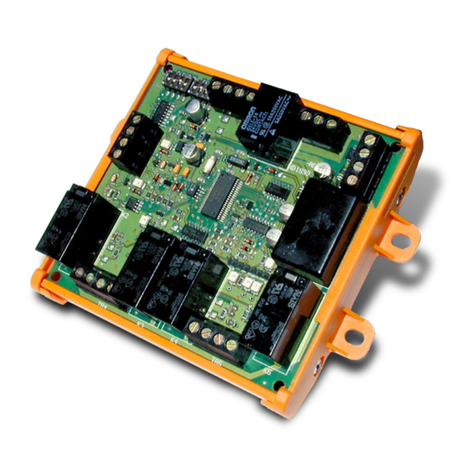

The Dual Zone Digital Location Control Unit is an optional component for any

Alarmline II Digital LHD system and offers enhanced monitoring and interfacing

features, as well as simple status indications and controls for monitoring the LHD

system.

Dual LHD zones are provided on the control unit, which enable the following

features:

• Two zones of sensor cable:Two monitored inputs allow connection of two

Alarmline II Digital Sensor Cables to one control unit. The sensor cables for

each zone are independent and can be different alarm temperatures if

required. The two zones of sensor cable can be used to protect two separate

risk areas or can be used to protect the same risk area using two different

temperature cables providing pre-alarm and alarm type system.

• Independent or interlock modes of operation:Each zone on the control

unit has alarm and fault outputs for independent signaling to a main fire alarm

control panel. The two zones can also be programmed in interlock mode –

this provides a coincidence scenario where both zones must be in alarm

before any alarm outputs are triggered.

The control unit provides open circuit fault monitoring of the digital sensor cable

with a short circuit on the digital cable activating an alarm condition.

Interposing cable can be used between the control unit zone input and the digital

sensor cable allowing the control unit to be mounted remotely to the risk area.

See “Interposing cable” on page 14 for more information.

Additional features provided by the control unit:

• Alarm location:Detecting the location of an overheat condition or flame

within the risk area can help reduce the response time to an incident (thus

minimizing the damage). The control unit can identify the point along the

sensor cable where the fire has occurred.

• Modbus interface:In many applications it can be advantageous to link the

LHD system to third party graphics or control systems. The Modbus output on

the control unit provides the capabilities to do this for each zone.