2 / 7 P/N P-047550-1816-EN • REV 007 • ISS 21SEP17

Personality Code 10: Alarm - NO delayed latching (Class A):

Same as code 9 except that contact closure must be

maintained for approximately 16 seconds before an alarm

signal is sent. Code 10 is typically used with waterflow alarm

switches.

Personality code 11: Active - NO nonlatching (Class A):

Same as code 9 except that contact closure causes an active

instead of an alarm status, and does not latch at the module.

Personality code 11 is typically used for monitoring fans,

dampers, and doors.

Personality code 12: Active - NO latching (Class A): Same as

code 9 except that contact closure causes an active instead of

an alarm status, which is latched at the module. Code 12 is

typically used for monitoring supervisory and tamper switches.

Personality code 13: Alarm - two-wire smoke unverified

(Class B): Configures the module for monitoring two-wire

conventional smoke detectors (that do not require alarm

verification) and normally open contact initiating devices (e.g.,

pull stations, heat detectors, etc.) on the same circuit.

Personality code 14: Alarm - two-wire smoke verified

(Class B): Configures the module for monitoring two-wire

conventional smoke detectors (that require alarm verification).

Normally open contact initiating devices may not be mixed with

two-wire conventional smoke detectors.

Personality code 15: Signal - supervised output (Class A):

Configures the module for connection of a Class A output

notification appliance circuit (NAC). Code 15 is typically used

to control bells, speakers, etc.

Personality code 16: Signal - supervised output (Class B):

Configures the module for connection of a Class B output

notification appliance circuit (NAC). Code 16 is typically used

to control bells, speakers, etc.

Personality code 20: Alarm - two-wire smoke unverified

(Class A): Same as personality code 13, except that wiring is

Class A.

Personality code 21: Alarm - two-wire smoke verified

(Class A): Same as personality code 14, except that wiring is

Class A.

For personality codes 13, 14, 20 and 21

First SIGA-UM on a loop to go into alarm will maintain the 2

wire detector circuit voltage and current so that the 2 wire

detector can maintain its LED. Second SIGA-UM on the same

loop to get an alarm from a 2 wire detector will indicate the

alarm at the control panel but will reduce voltage and current

on its 2 wire circuit causing the detector LED to turn on and off.

Installation

WARNINGS

•Connecting a device that exceeds this module’s pilot duty

contact ratings may cause activation failure. This module

does not support capacitive loads. See “Specifications” on

page 6 for contact ratings.

•The personality code for this device is factory set to 0.

This module will not operate until it is assigned a

personality code of 1, 2, 3, 4, 8, 9, 10, 11, 12, 13, 14, 15,

16, 20, or 21.

•Electrocution hazard. Dangerous voltages may be present

at the module terminals even when power is shut off.

Notes

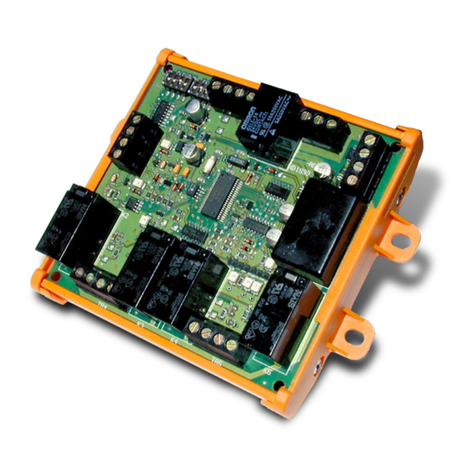

•The module is shipped from the factory as an assembled

unit; it contains no user-serviceable parts and should not

be disassembled.

•This module does not operate without electrical power. As

fires frequently cause power interruption, discuss further

safeguards with the local fire protection specialist.

•This module does not support conventional four-wire

smoke detectors.

Install in accordance with all applicable local codes and

standards and the local authority having jurisdiction.

To install the module:

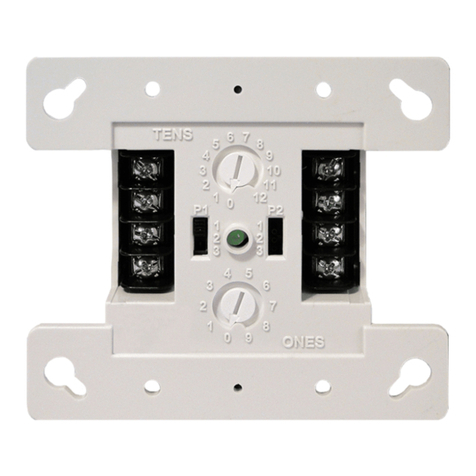

1. Wire in accordance with “Wiring” on page 3.

2. Write the address assigned to the module on the label

provided and apply the label to the module. Remove the

serial number label from the detector and attach it to the

project documentation.

3. Using the screw provided, mount the wall plate to the

module. See Figure 1 on page 3 for mounting details.

4. Using the screws provided, mount the wall plate (with the

module attached) to one of the compatible electrical boxes

listed in “Specifications” on page 6.